Efficient cleaning device

A cleaning device and high-efficiency technology, applied in cleaning methods and utensils, cleaning methods using liquids, multi-stage water/sewage treatment, etc., can solve problems such as unfavorable sedimentation space, and achieve increased cleaning strength, efficient washing, and water quality improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

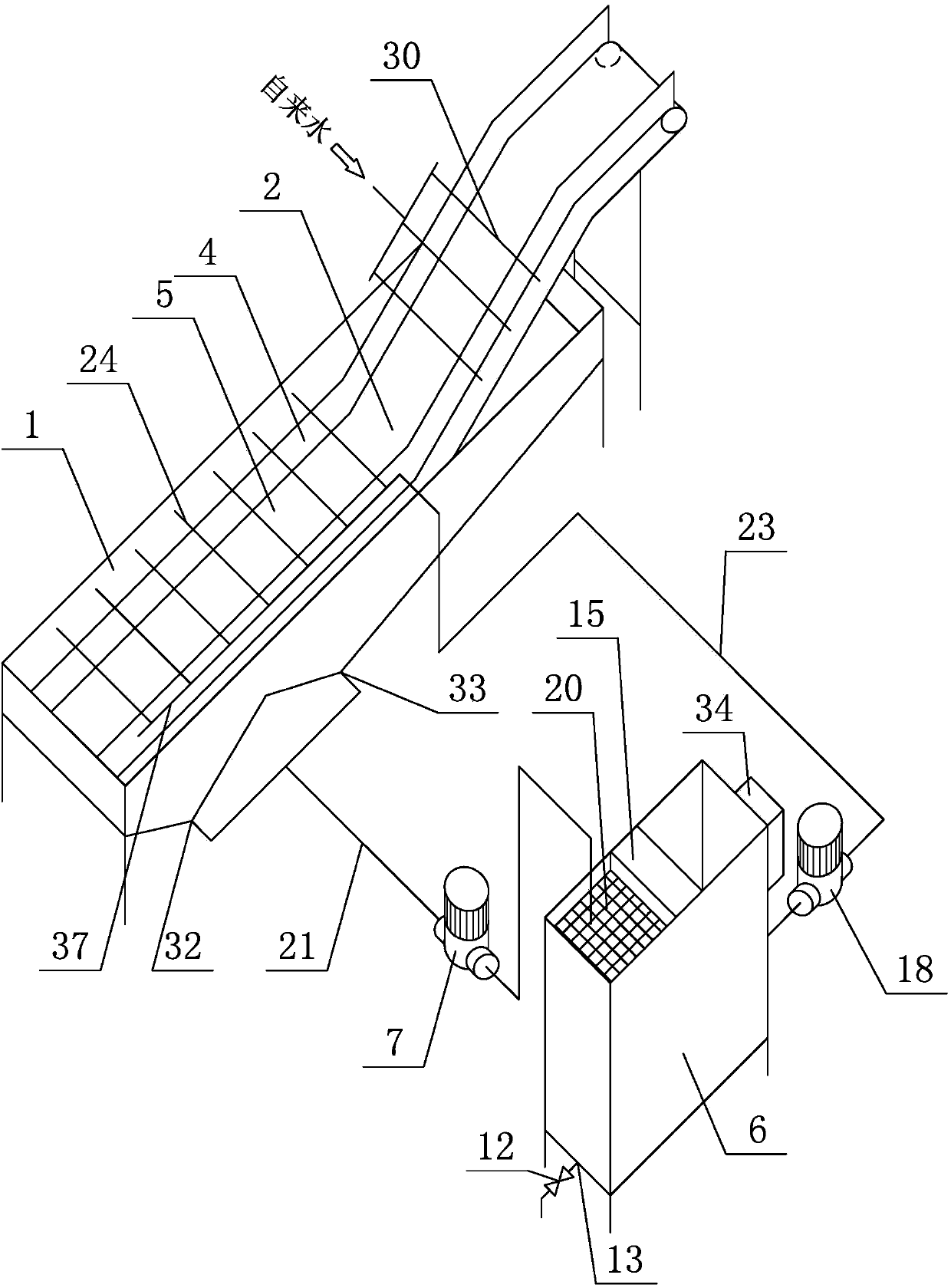

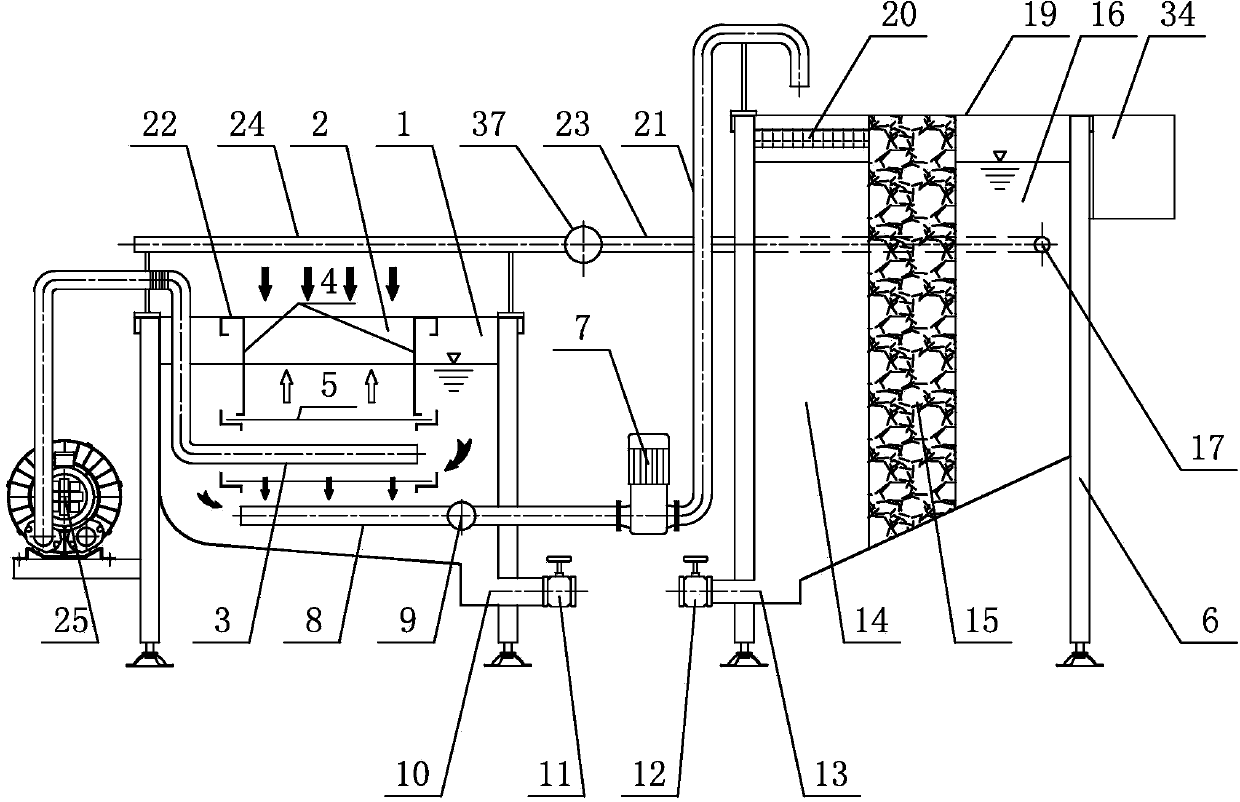

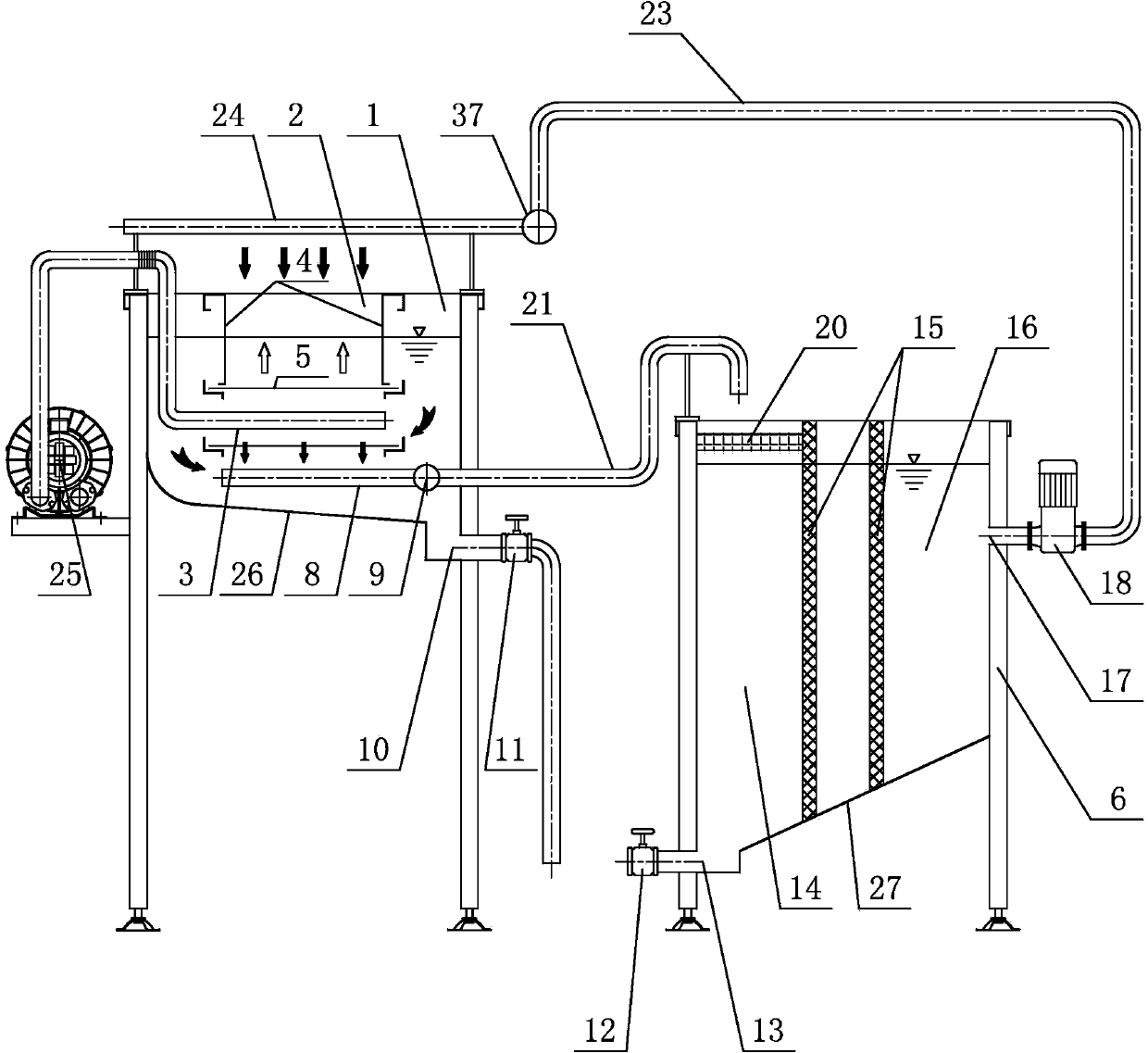

[0034] Such as figure 1 , figure 2 with image 3 As shown, the present invention is composed of a cleaning tank 1, a material washing tank 2, a pipeline 21, a pipeline 23, a circulating water treatment tank 6, and the like. The washing tank 1 and the washing tank 2 are rectangular containers with an open upper part respectively. The washing tank 2 is in the washing tank 1, and the material can be placed in the washing tank 2 for cleaning. The cleaning tank 1 can contain water, and the bottom is provided with a sewage outlet 10 and a sewage valve 11 for emptying or cleaning the tank body. The material washing tank 2 is composed of a wall 4 and a bottom 5. The wall 4 and the bottom 5 are provided with uniformly distributed mesh holes 28 or slits 29 composed of sticks arranged. The material washing tank 2 communicates with the water in the washing tank 1. , Figure 4 Shown is a shape of hole 28, Figure 5 Shown is a seam 29 shape. One or more gas pipes 3 are arranged under the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com