Sintering and pelletizing flue gas SCR denitration and dioxin removal apparatus

A dioxin and SCR reactor technology, which is applied in the field of denitrification and dioxin removal devices, can solve the problems of difficult promotion, high initial investment and operation costs, and achieve the effects of low ammonia escape rate, reduced blockage, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

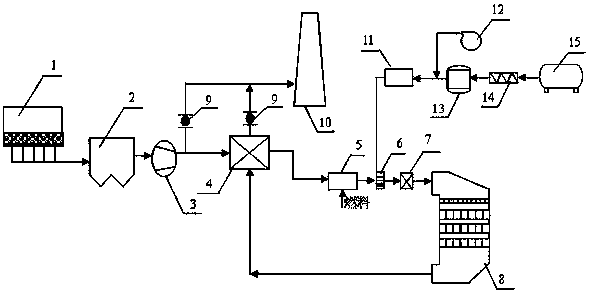

[0030] The connection mode of each equipment in the sintering and pelletizing flue gas SCR denitrification and dioxin removal device of this embodiment is as attached figure 1shown. The device includes a rotary flue gas heat exchanger 4, a duct burner 5, an ammonia injection grid 6, a flue gas mixer 7, an SCR reactor 8 and an ammonia-air mixer 11, and the rotary flue gas heat exchanger 4 includes The first cold-end inlet flue, the first hot-end outlet flue, the second hot-end inlet flue, and the second cold-end outlet flue, wherein the first cold-end inlet flue is connected to the sintering and pelletizing main exhaust fan 3 The outlet flue of the SCR reactor 8 is connected to the outlet flue of the first hot end of the rotary flue gas heat exchanger 4; the pipe burner 5, the ammonia injection grid 6, and the flue gas mixer 7 are arranged in sequence Between the rotary flue gas heat exchanger 4 and the SCR reactor 8, specifically, it is arranged inside the flue connecting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com