Zoning-regulating double-layer ammonia injection grid applied to selective catalytic reduction denitrification device for industrial flue gas

A technology of ammonia injection grille and industrial flue gas, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problem of uneven distribution of flue gas flow rate, large difference in ammonia injection amount, and uneven distribution of ammonia, etc. problem, to achieve the effect of optimizing the uniform mixing effect, uniform distribution, and reducing the ammonia escape rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

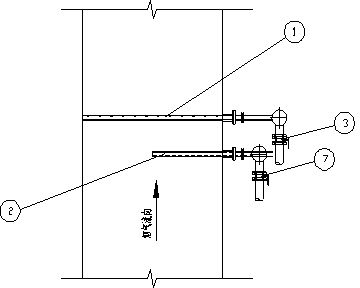

[0019] figure 1 The ammonia injection grille (1) in the middle and upper layers is connected to the inner wall of the flue and arranged vertically on the flue section, covering the entire flue section. The lower ammonia injection grille (2) is vertically arranged on the flue section after being connected to the inner wall of the flue, and covers 1 / 2 of the flue section. The distance between the upper ammonia injection grid (1) and the lower ammonia injection grid (2) is 400mm-500mm.

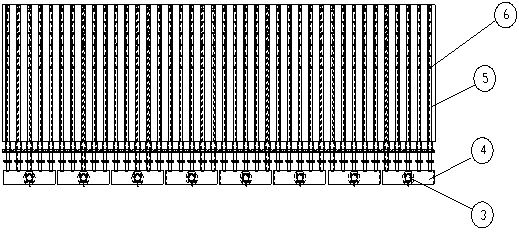

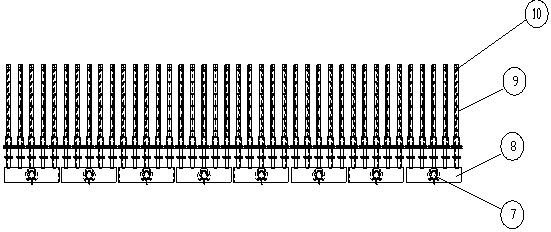

[0020] The upper ammonia injection grid (1) and the lower ammonia injection grid (2) of the present invention are composed of ammonia injection control valves (3,7), ammonia injection main pipes (4,8), ammonia injection branch pipes (5,9) composition. Each ammonia injection control valve (3,7) controls the ammonia injection flow rate of one ammonia injection main pipe (4,8), and is connected to five ammonia injection branch pipes (5,9). The ammonia injection branch pipes (5, 9) of the upper am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com