SCR (Selective Catalytic Reduction) flue gas denitration system control method and apparatus

A flue gas and denitrification technology, applied in the field of flue gas denitrification, can solve the problems of high cost of denitrification system, lagging measurement signal, high ammonia escape rate, etc., achieve the effect of reducing escape rate, strong nonlinearity, and improving denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

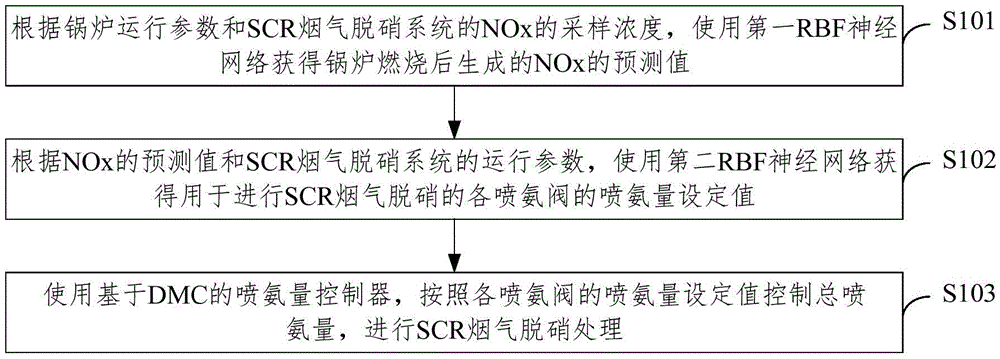

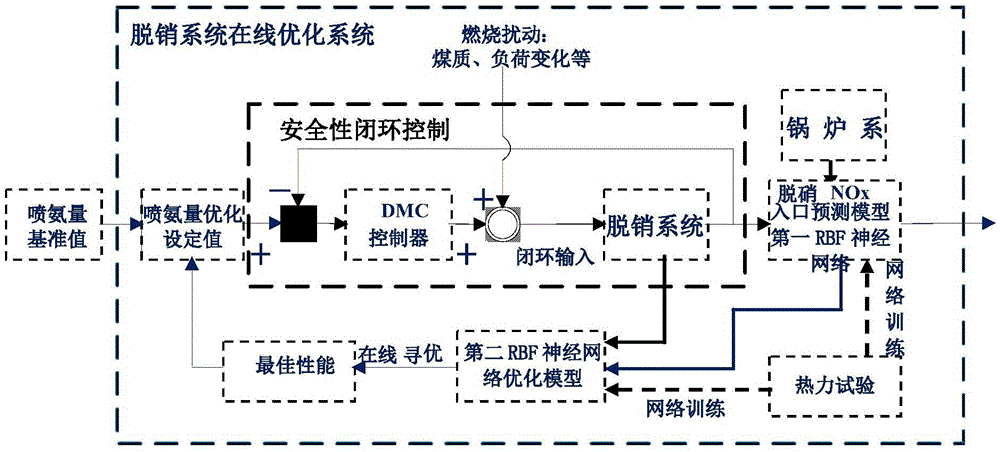

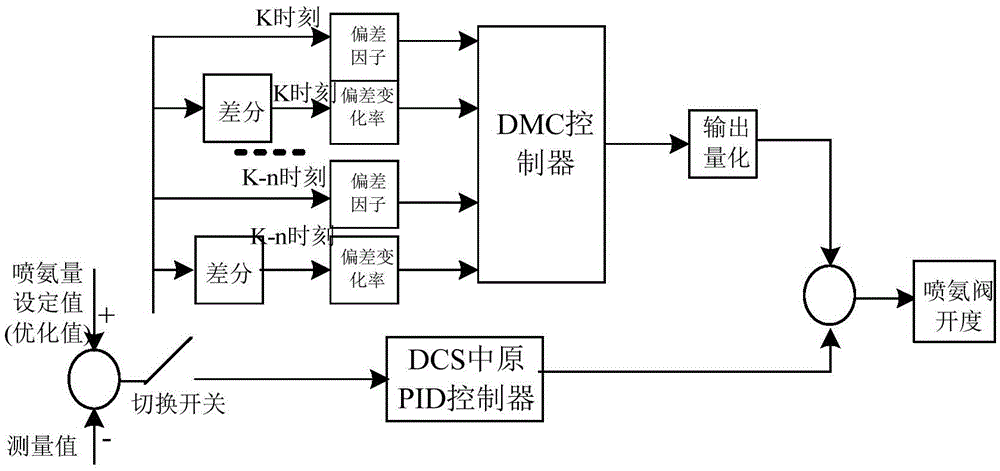

[0017] In order to make the purpose, technical solution and advantages of the present invention more clear. The technical solution of the present invention will be clearly and completely described below, and it is obvious that the described embodiments are part of the embodiments of the present invention, rather than all embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

[0018] SCR denitrification is in the range of suitable working temperature (290-430 degrees Celsius) and under the condition of aerobic participation, the reducing agent selectively reduces the NOx in the flue gas to non-toxic and pollution-free N under the action of the catalyst. 2 and H 2 O process. The key to the optimal design and operation of the SCR denitrification system is how to ensure that the flow field, temperature field and reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com