Denitration process and denitration apparatus for cement kiln flue gas

A cement kiln and flue gas technology, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of shortening the service life of the catalyst, increasing the operating cost, and deactivating the catalyst, so as to reduce the investment and operation cost, save the occupation land area, the effect of reducing the ammonia escape rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

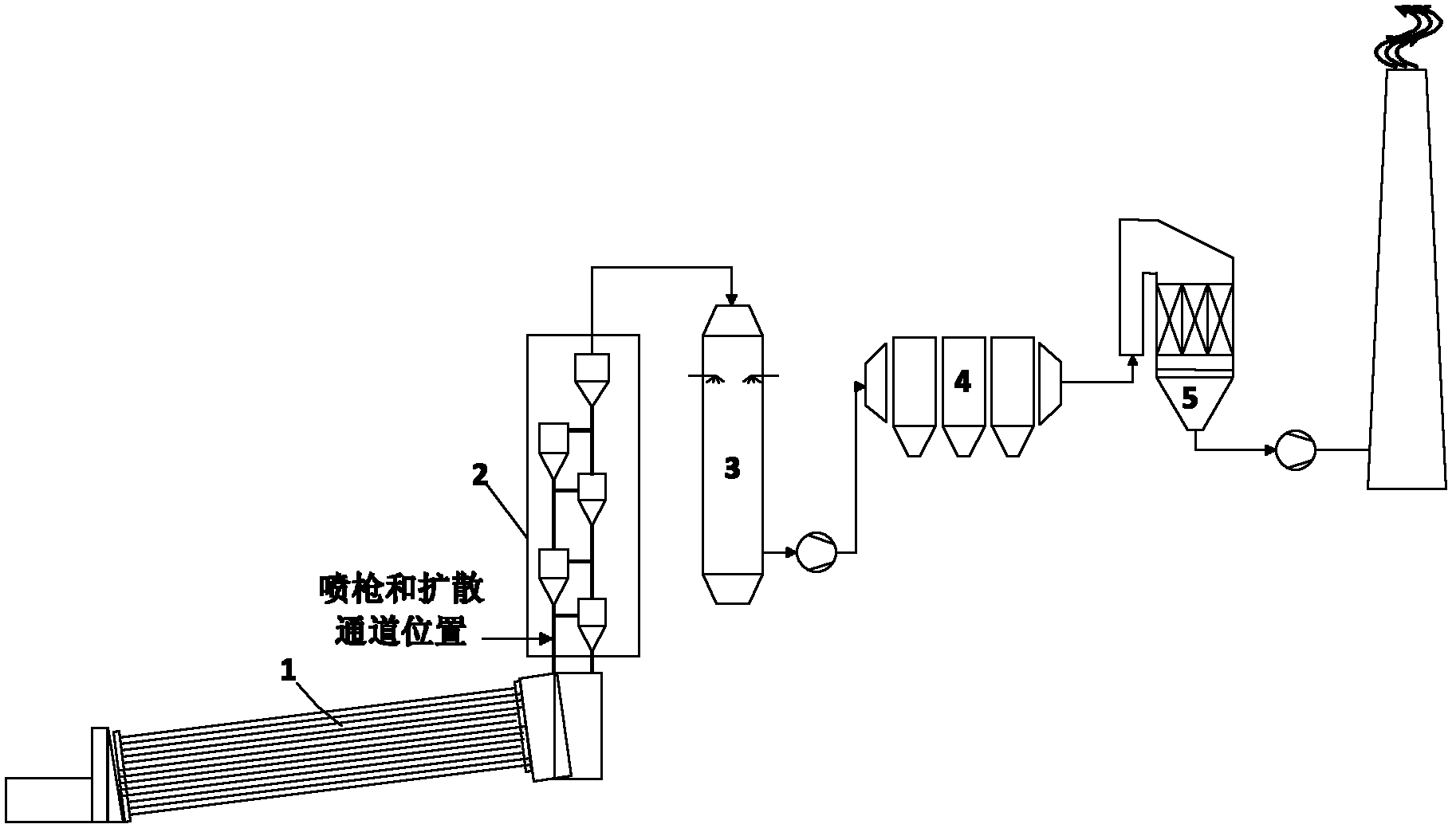

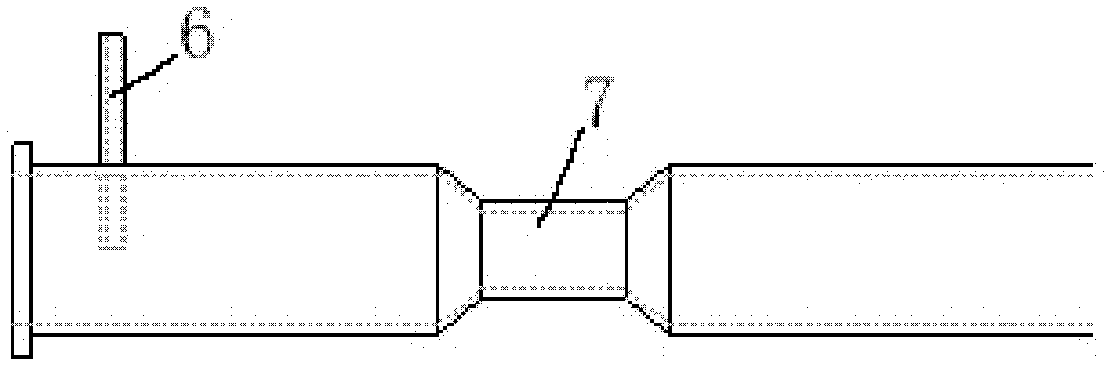

[0024] Such as figure 1 The shown cement kiln flue gas denitrification device includes a cement decomposition kiln 1, a waste heat boiler 2, a humidifying tower 3, a dust collector 4 and an SCR reactor 5 connected in sequence, and the SCR reactor is a honeycomb reactor. In the temperature range of 750℃~1100℃, the concentration of nitrogen oxides is 600mg / m 3 A spray gun is arranged at half of the tail flue of the cement decomposition kiln 1, and a contraction diffusion channel is arranged behind the spray gun (such as figure 2 As shown), the reducing agent is injected according to the molar ratio of the injected amount of the reducing agent to the molar ratio of nitrogen oxides in the flue gas of 2.0:1, and the injection speed is 15m / s. The reducing agent is mixed with the flue gas in the flue, and has a selective non-catalytic reaction with nitrogen oxides, and most of the NO X reduced to N 2 .

[0025] The SCR reactor is arranged at the tail of the dust collector 4 with...

Embodiment 2

[0027] A cement kiln flue gas denitrification device, comprising a cement decomposition kiln 1, a waste heat boiler 2, a humidification tower 3, a dust collector 4 and an SCR reactor 5. The difference from Example 1 is that the SCR reactor 5 is installed Between the humidification tower 3 and the dust collector 4.

[0028] In the temperature range of 750℃~1100℃, the concentration of nitrogen oxides is 600mg / m 3 The spray gun 6 is arranged at one-half of the tail flue of the cement decomposition kiln 1, and the reducing agent is injected according to the injection amount of the reducing agent and the molar ratio of nitrogen oxides in the flue gas is 2.4:1, and the injection speed is is 15m / s. The reducing agent is mixed with the flue gas in the flue, and has a selective non-catalytic reaction with nitrogen oxides, and most of the NO X reduced to N 2 .

[0029] The SCR reactor 5 is arranged at the tail of the humidification tower 3 with a temperature of about 160°C. It is lo...

Embodiment 3

[0031] A cement kiln flue gas denitrification device, the equipment layout is the same as in Example 2, the temperature range is 750°C to 1100°C, and the nitrogen oxide concentration is 550mg / m 3 A spray gun is arranged at half of the tail flue of the cement decomposition kiln 1, and the reducing agent is injected according to the molar ratio of the injected amount of the reducing agent to the nitrogen oxide in the flue gas being 2.0:1. The reducing agent is mixed with the flue gas in the flue, and has a selective non-catalytic reaction with nitrogen oxides, and most of the NO X reduced to N 2 .

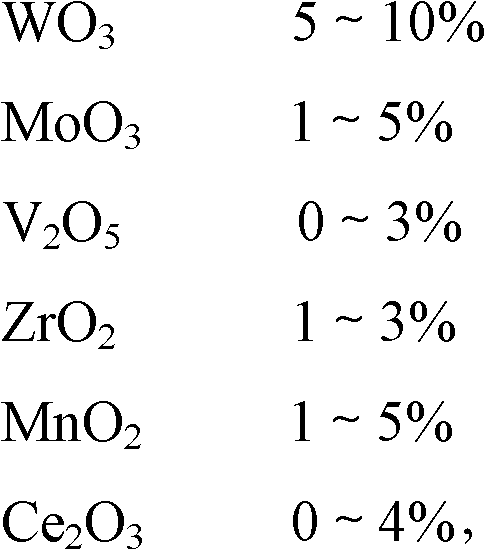

[0032] The SCR reactor 5 is arranged at the tail of the humidification tower 3 with a temperature of about 160°C. It is loaded with a honeycomb-shaped, medium-low temperature and high-activity catalyst that is resistant to alkaline earth alkali metals. Its active components mainly include: 8.5% WO 3 , 3.6% MoO 3 , 2.9% V 2 o 5 , 2.8% ZrO 2 , 4.2% MnO 2 , 3.3% Ce 2 o 3 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com