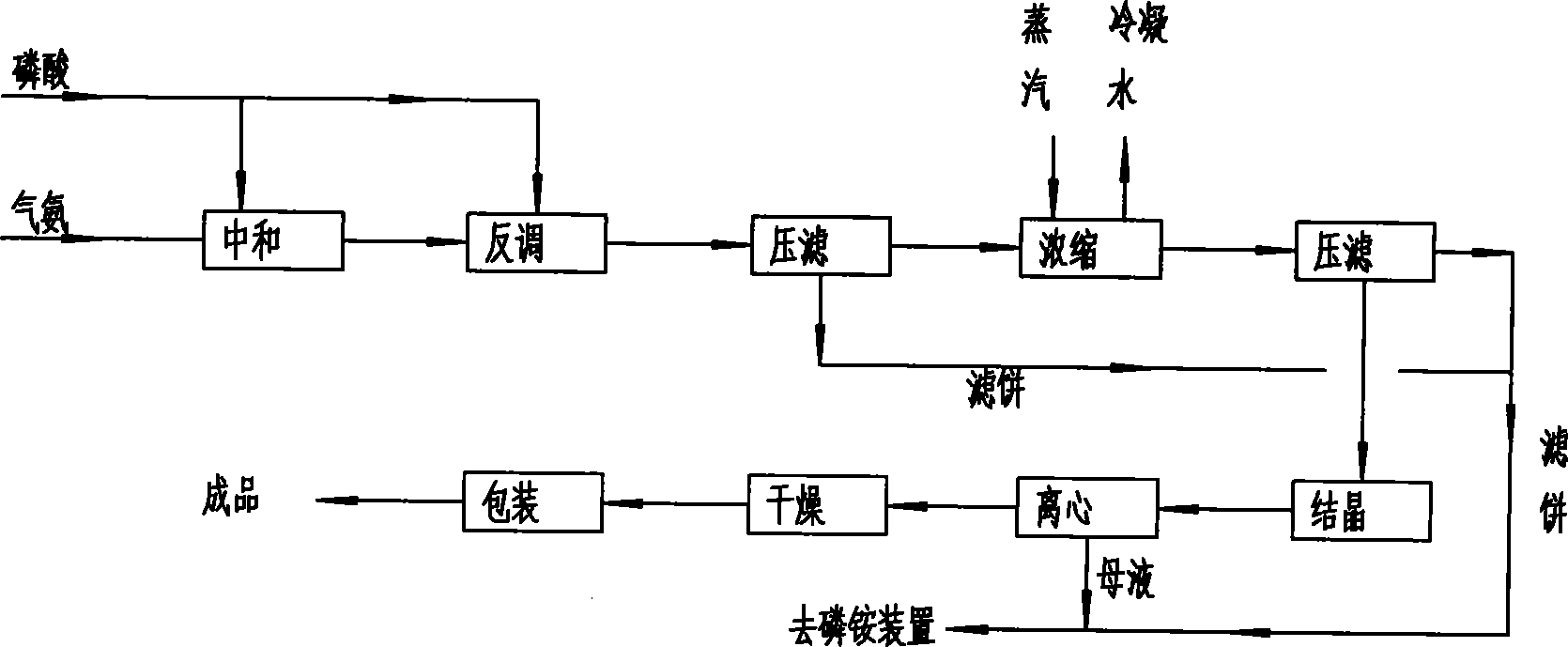

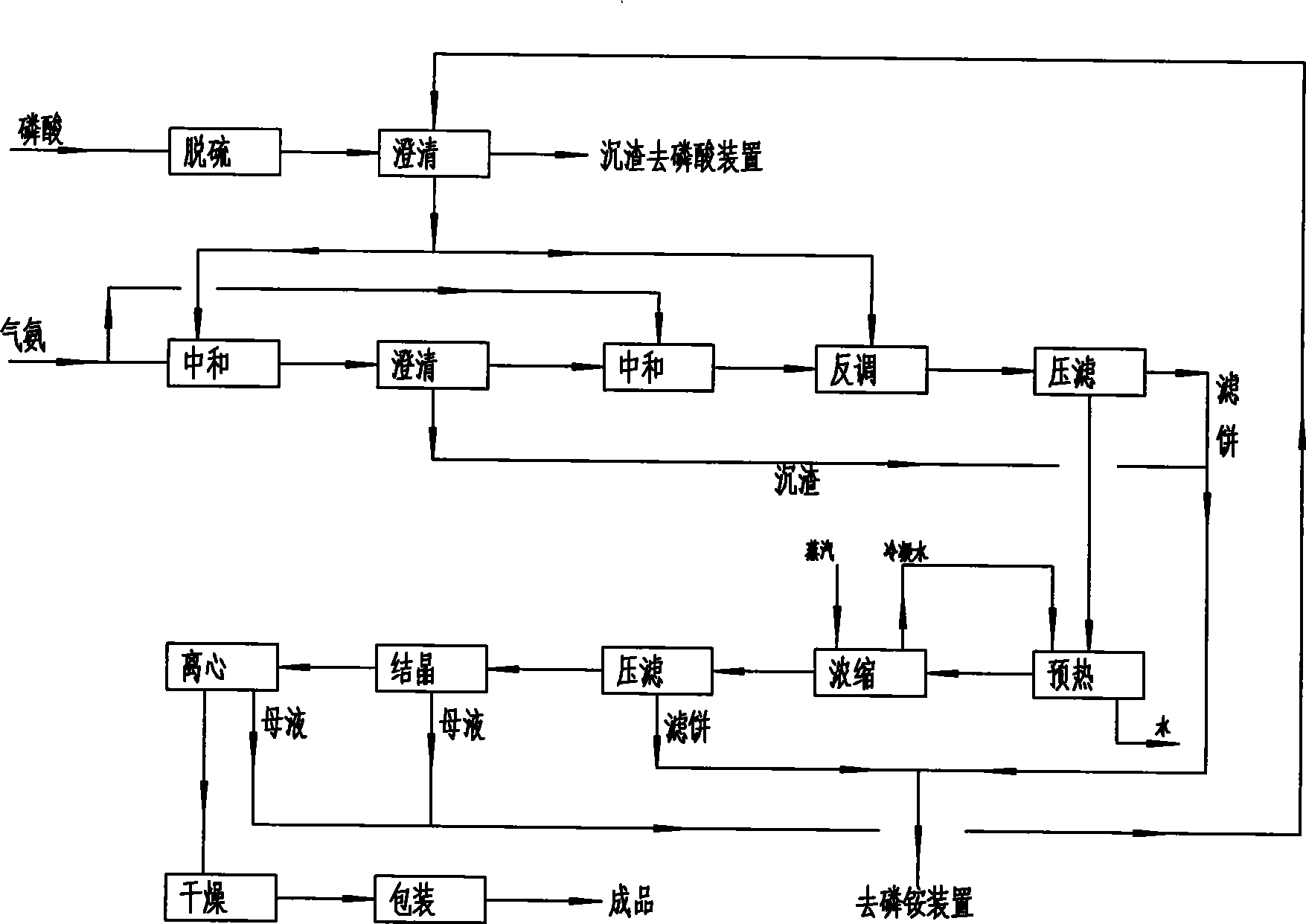

Process for continuous production of technical grade mano-ammonium phosphate with wet-process and phosphoric acid

A technology of wet-process phosphoric acid and monoammonium phosphate, which is applied in the direction of phosphate, phosphorus oxyacid, etc., can solve the problems of non-recyclable mother liquor, low production capacity, and high labor intensity, so as to save steam consumption, large production capacity, Effect of reducing steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The technique for the continuous production of industrial-grade monoammonium phosphate by wet-process phosphoric acid is characterized in that it comprises the following steps:

[0039] 1) Put phosphoric acid and phosphate rock slurry into the desulfurization reaction tank in proportion to control SO in phosphoric acid 3 The molar ratio to CaO in the phosphate rock slurry is 1:1.05, stirring for desulfurization reaction, the resulting reaction slurry overflows to the phosphoric acid buffer tank, and is sent to the phosphoric acid clarification tank by the phosphoric acid pump for sedimentation and separation, and the supernatant is desulfurized phosphoric acid. The bottom layer of the phosphoric acid clarification tank is pumped to the phosphoric acid plant for the phosphoric acid sediment;

[0040] 2) The desulfurized phosphoric acid obtained in step 1) and gaseous ammonia are neutralized for the first time in a tank-type neutralization reactor, and the pH value is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com