Tangential double vortex SCR mixer

A mixer and double eddy current technology, applied in fluid mixers, mixers, chemical instruments and methods, etc., can solve the problems of increased system pressure drop, increased power consumption of induced draft fans, etc., to solve the problem of insufficient ammonia mixing distance, Advantages of manufacturing costs and maintenance costs, the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

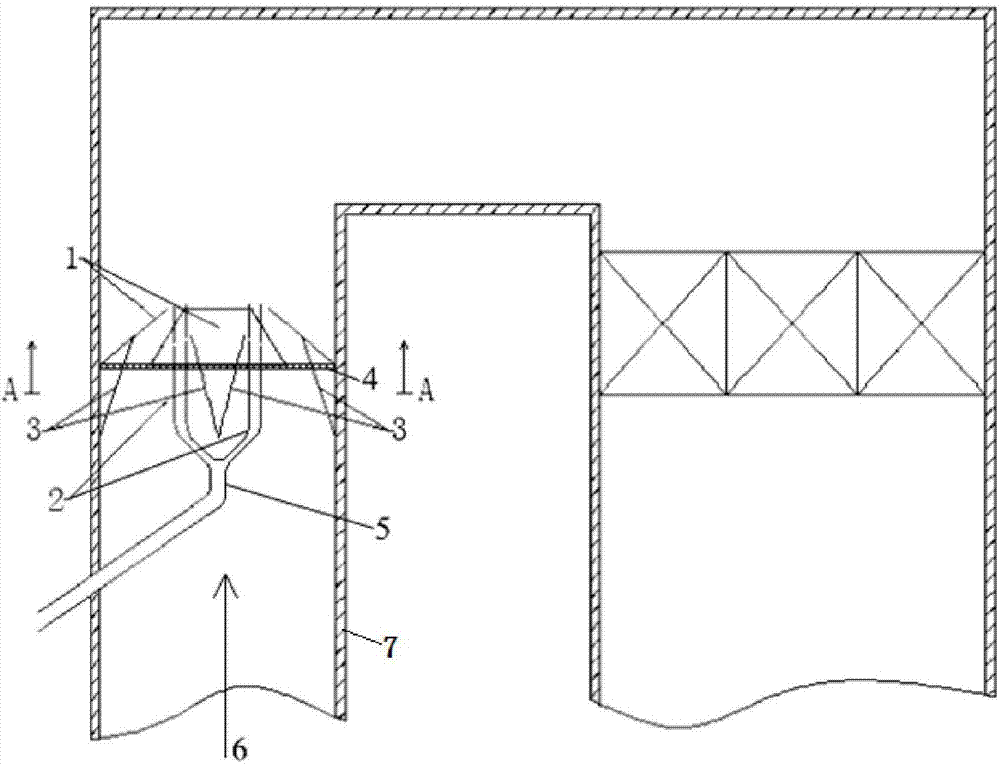

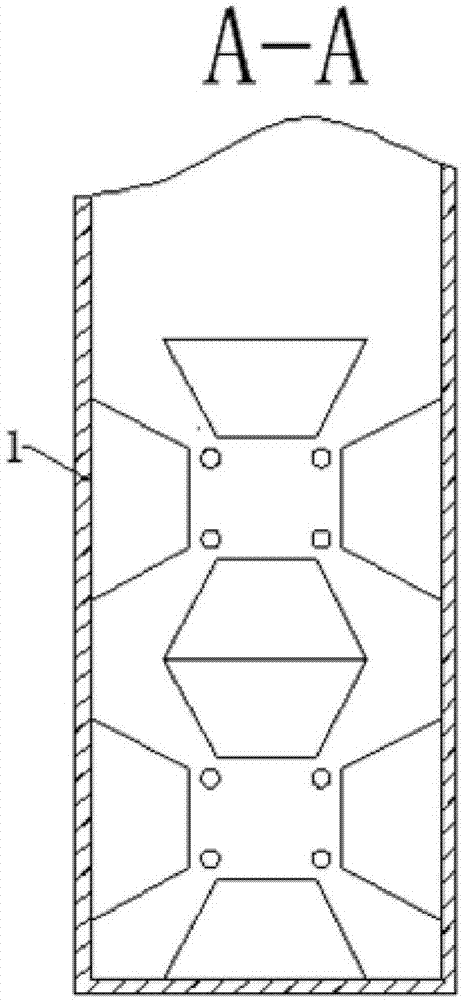

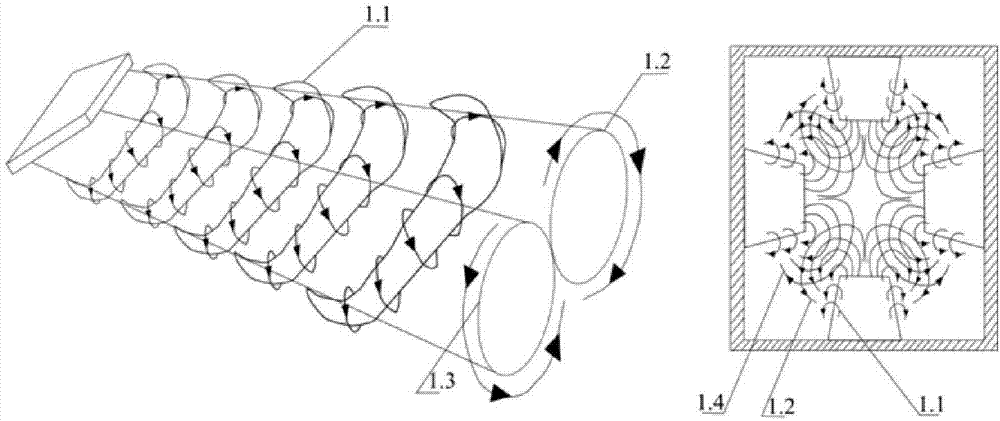

[0022] Such as figure 1 with figure 2 As shown, a tangential double vortex SCR mixer, a group of support beams 4 are equidistantly arranged on the section of the flue 7, and the support beams 4 divide the section of the flue into several mixer unit areas, and the mixer The unit area includes a group of mixer units, the mixer unit includes a group of trapezoidal plates 1, a group of nozzles 2, support beams 4, support rods 3, the bottom edge of the trapezoidal plates 1 is connected with the support beams 4, and the support One end of the rod 3 is fixed on the trapezoidal plate 1, and the other end is fixed on the inner wall of the flue 7, the trapezoidal plate 1 is downward and at 30°-60° to the incoming smoke 6; each nozzle 2 is set on the adjacent trapezoidal Between the plates 1, a group of nozzles 2 share an air supply branch pipe 5; the support beam 4 has a squa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com