Desending catalytic cracking reactor and its application

A catalytic cracking and reactor technology, applied in catalytic cracking, cracking, petroleum industry, etc., can solve the problems of equipment coking, insufficient heavy oil conversion capacity, low oil contact efficiency, etc., to reduce pulsation and back mixing, and strengthen heavy oil conversion Ability, the effect of preventing serious coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This example illustrates that the product distribution and product properties can be significantly improved by adopting the descending reactor provided by the present invention.

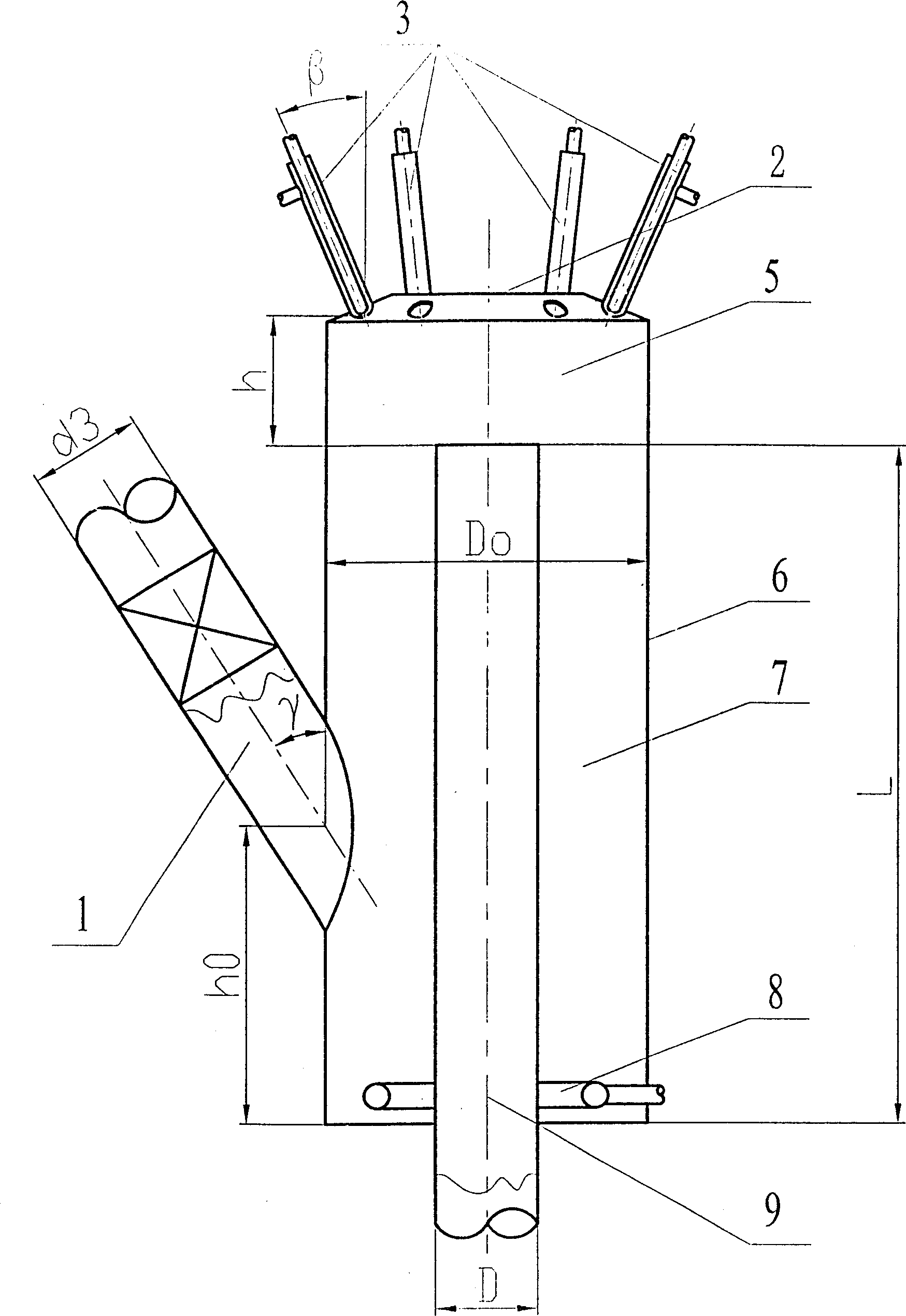

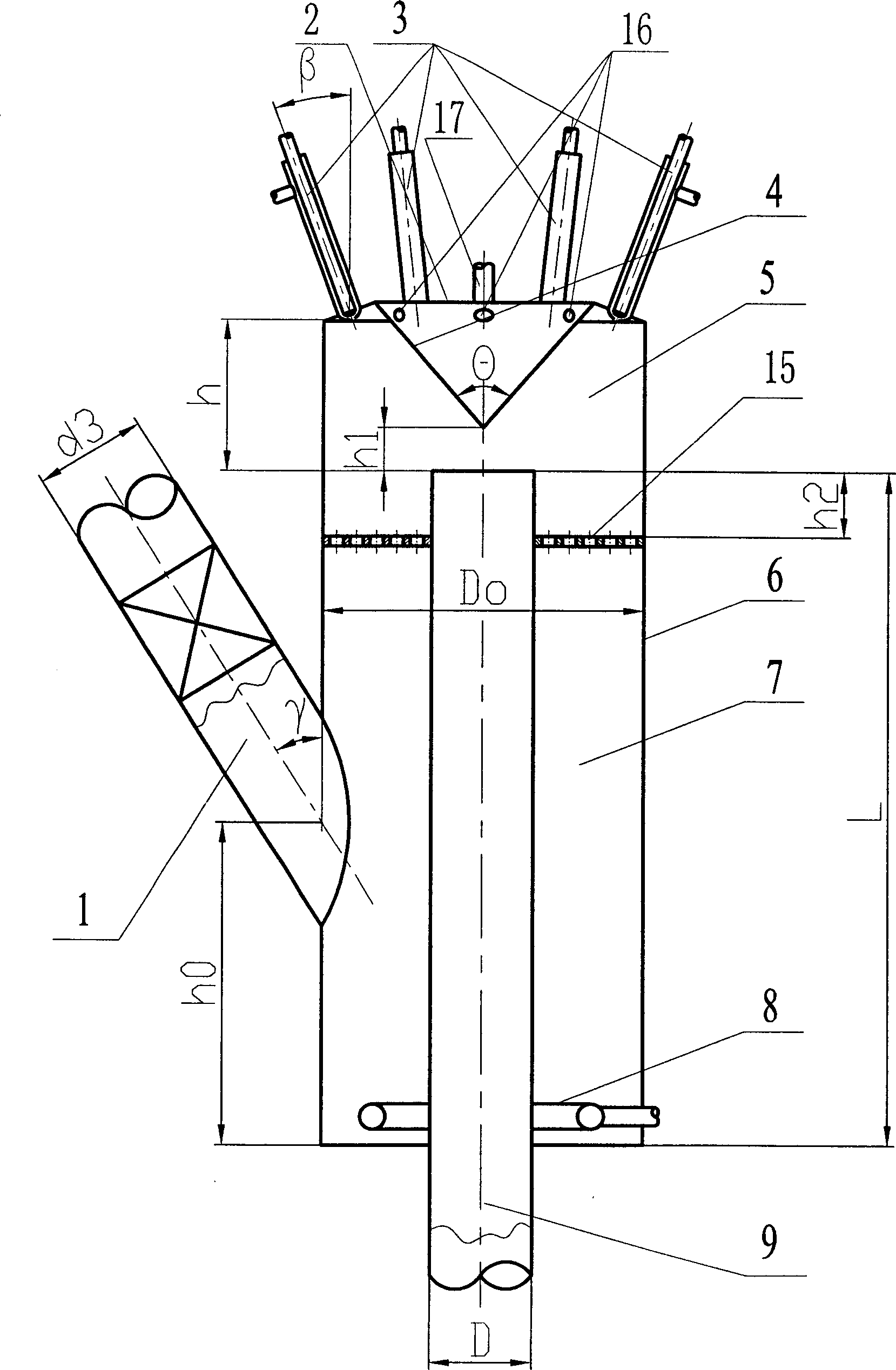

[0042] The principle flow chart of the catalytic cracking medium-sized unit used in the test Figure 11 , the structural diagram of the down-flow reactor is shown in figure 1 . The diameter of the descending reaction tube D=20mm; the diameter of the outer cylinder Do=2.5D; the height difference L=6D between the inlet of the descending pipe and the bottom of the outer cylinder; the number of nozzles is 4; the angle between each nozzle and the vertical direction β=30°, the height difference h=1.25D from the outlet of the nozzle to the inlet of the down pipe; the diameter of the catalyst delivery pipeline d3=0.8D, the angle between the center line and the vertical direction γ=30°, the catalyst delivery pipe and the outer The height difference h0=3D from the intersection point of the cylinder t...

Embodiment 2

[0045] This example illustrates that the product distribution and product properties can be significantly improved by adopting the descending reactor provided by the present invention.

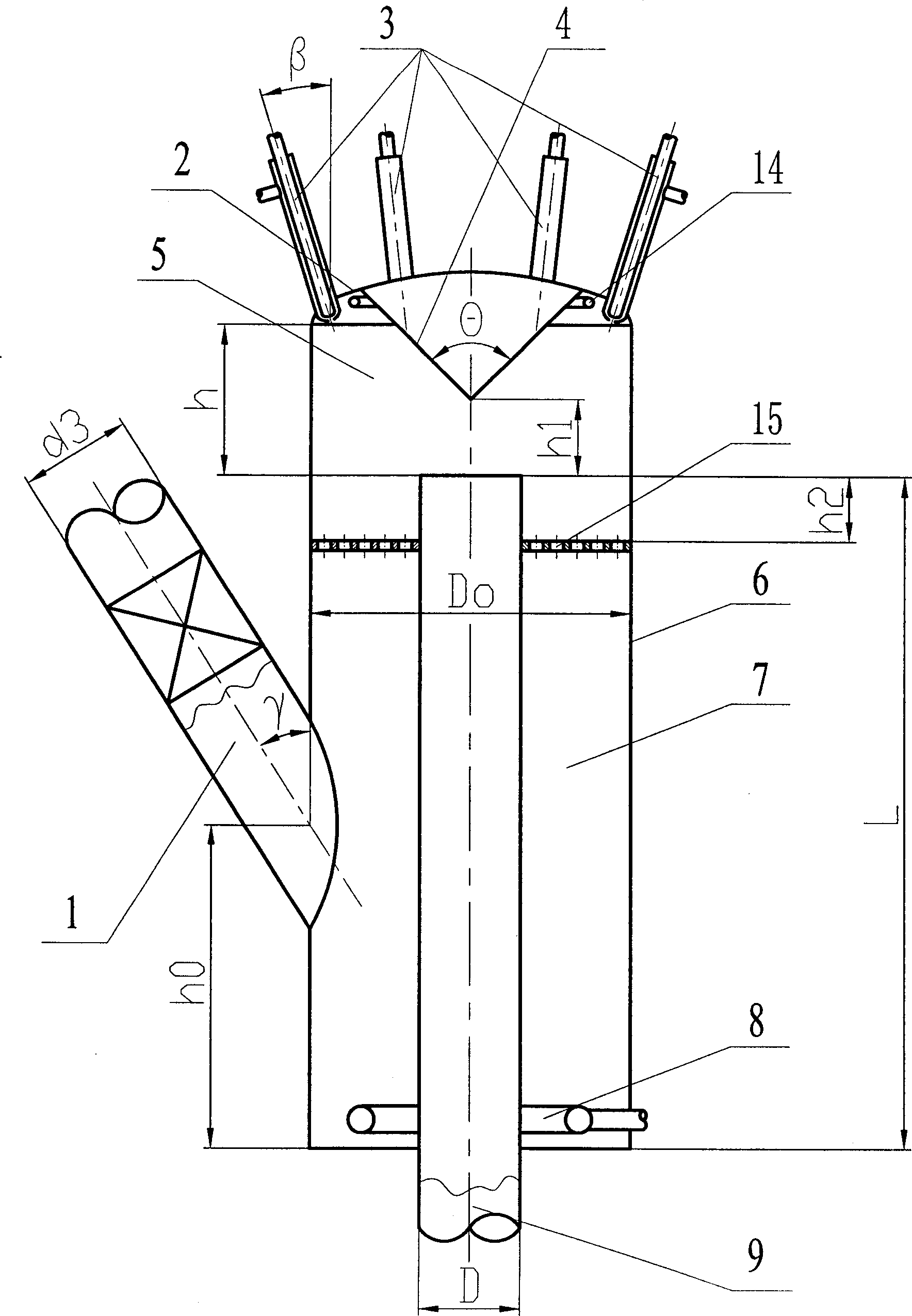

[0046] The principle flow chart of the catalytic cracking medium-sized unit used in the test Figure 12 , the structural diagram of the down-flow reactor is shown in Figure 10 . The diameter of the downcomer reactor is D=20mm; the cone angle of the outer cylinder is β0=22.5°, and the diameter of the lower opening is Db=2D; the height difference from the upper edge of the inlet structure of the downcomer to the bottom of the outer cylinder is L=6D ; The number of nozzles is 4; the angle β=45° between each nozzle and the vertical direction, the height difference h=1.35D from the exit of the nozzle to the upper edge of the down pipe narrowing section; the diameter of the cone bottom of the diversion cone Dt= 3D, its cone angle =100°, the height difference h1=0.5D from the upper edge of the do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com