Method for improving denitration rate of SCR (Selective Catalytic Reduction) denitration system of power station boiler

A technology of power plant boiler and denitration rate, applied in the field of SCR denitration system of coal-fired power station, can solve the problems of affecting the denitration effect of the system and the harm of economic and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described further below by embodiment.

[0032] The embodiment of the present invention conducts field operation optimization test research on the SCR device of a 600MW unit in a certain power plant.

[0033] 1. Optimized test and measuring instruments for on-site operation

[0034] (1) NO x and O 2 Measurement

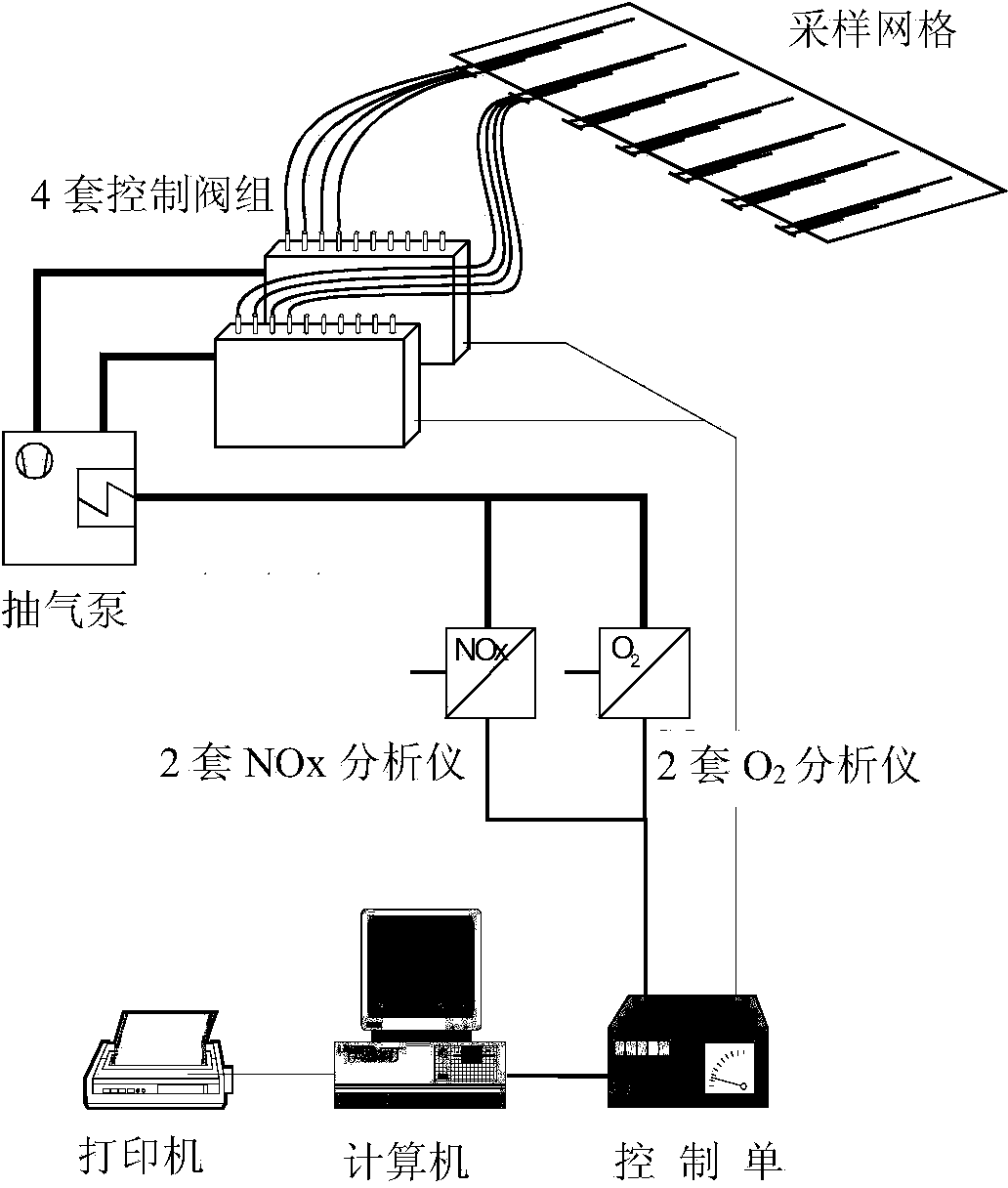

[0035] Field test NO x The measuring instrument is infrared NO x Analyzer, O 2 The measuring instrument is usually a paramagnetic oxygen meter. Due to the large area of the SCR reactor, it is usually necessary to adopt such image 3 The automatic measurement system shown.

[0036] by NOx and O 2 Simultaneous measurement of NOx data converted to 6%O 2 benchmark data.

[0037] (2) NH 3 Measurement

[0038] Field Trial NH 3 The measurement can be in accordance with the EPAmethodCTM027 standard, the sampling system such as image 3 shown.

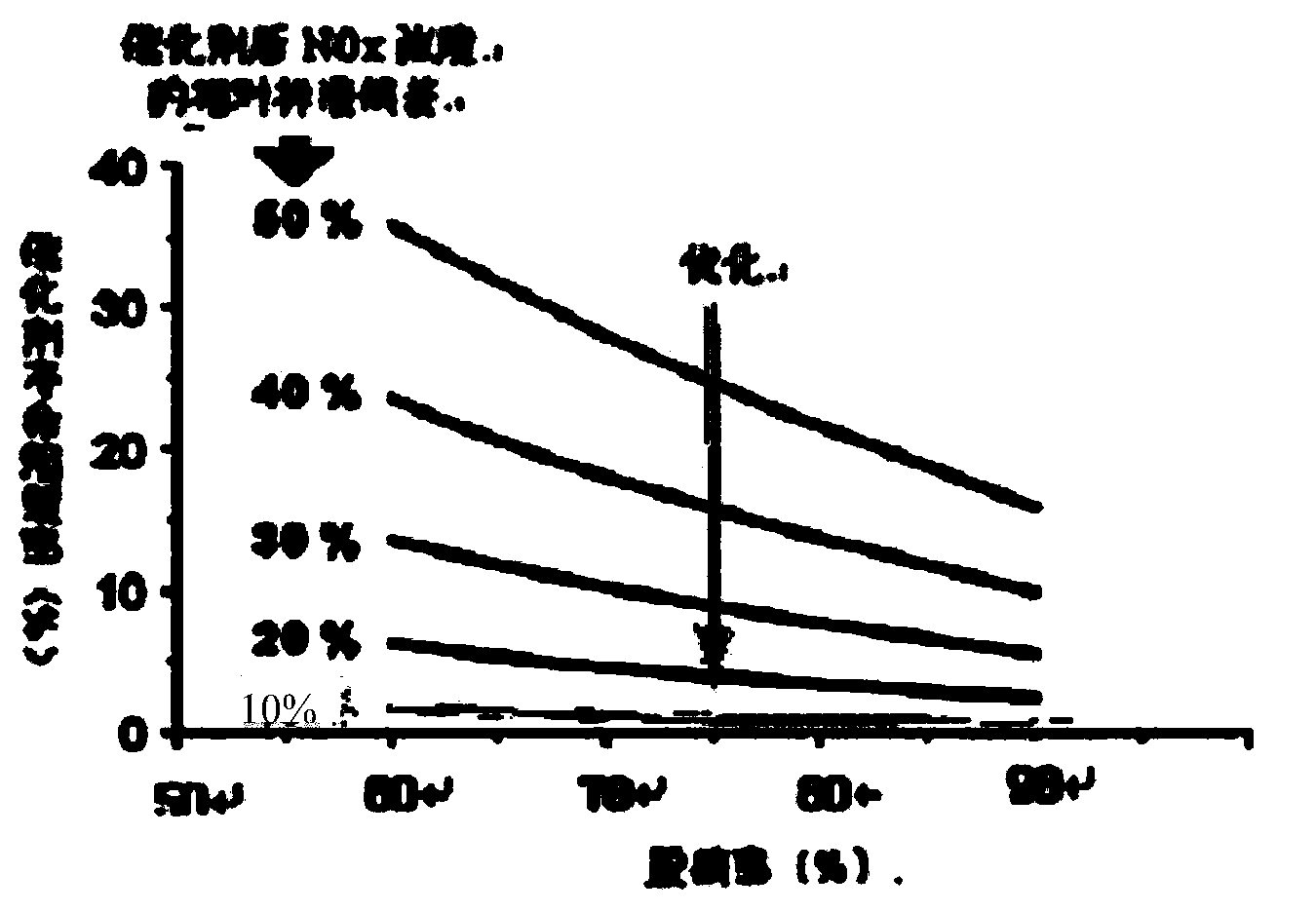

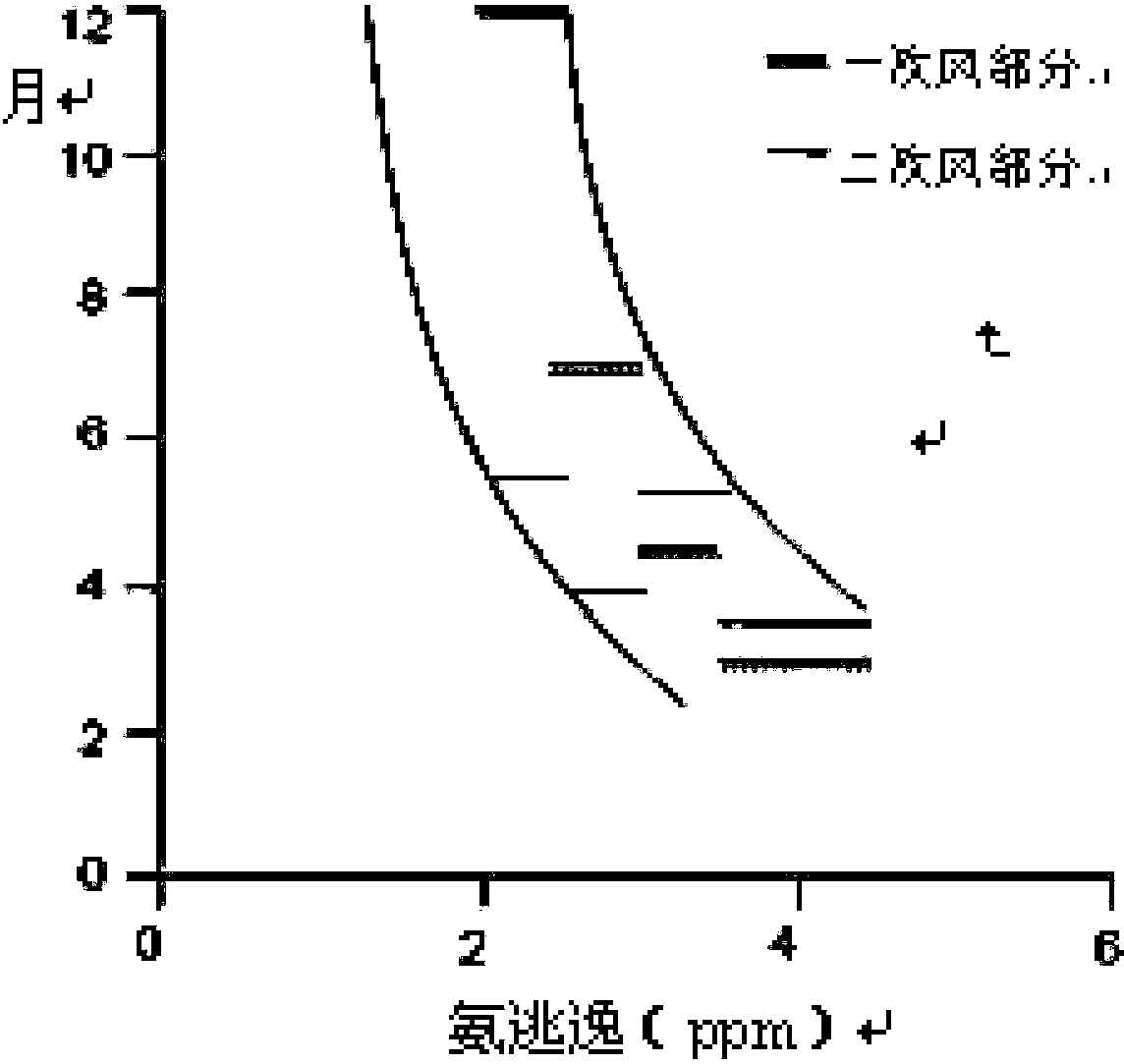

[0039] 2. Analysis and discussion on field operation optimization practice

[0040...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com