Gas explosion coal seam permeability increasing extraction method in borehole in later period of induction extraction

A drilling and drainage technology, which is applied in the direction of gas discharge, mining equipment, earthwork drilling, etc., can solve the problems of limited penetration range, uneven and discontinuous detonation gas concentration distribution area, and achieve high transmission efficiency of explosion wave , Increase the development of coal fractures and the uniform distribution of gas concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

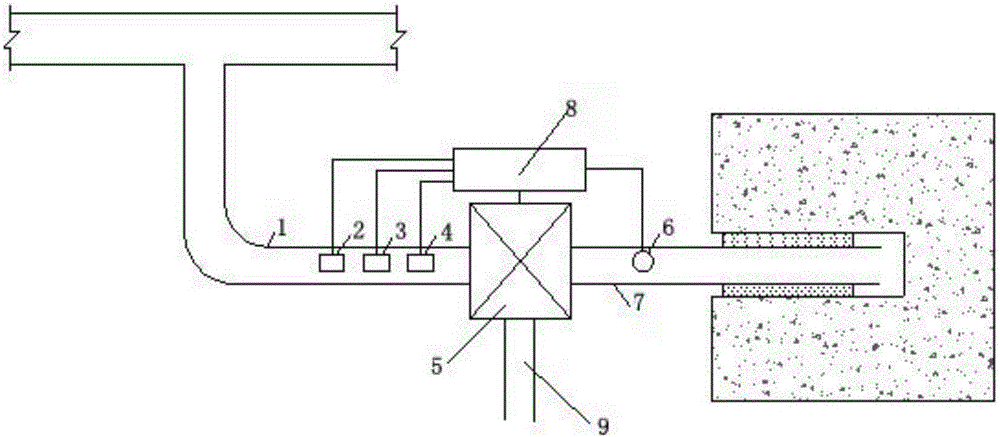

[0028] a. Insert the 20m-long gas extraction pipe 7 into a borehole with a diameter of 94mm and a depth of 100m, then seal the borehole with pressurized cement grouting, install the gas concentration monitoring device 2, carbon monoxide monitoring device 3, temperature The monitoring device 4 is set on the pipeline of the underground negative pressure drainage main pipeline 1, and the spark generator 6 is set on the pipeline of the gas drainage pipe 7. By what means are the spark generator 6 connected to the gas concentration monitoring device 2 and the carbon monoxide monitoring device? Device 3 and temperature monitoring device 4 are isolated and separated by three-way ball valve 5;

[0029] b. When the gas concentration monitoring device 2 monitors that the gas concentration in the gas extraction pipe 7 is 9.3%, close the three-way ball valve 5, and connect the power to the spark generator 6 to cause the gas in the borehole to detonate;

[0030] c. After the gas explosion i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com