Solution dehumidifying and regenerating device

A solution dehumidification and regeneration device technology, which is applied in household heating, lighting and heating equipment, space heating and ventilation, etc., can solve the problem of unfavorable heat and mass exchange between solution and humid air, reduction of mass transfer potential difference, and damage to heat transfer In order to achieve uniform distribution of solution concentration, avoid corrosion, and reduce pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

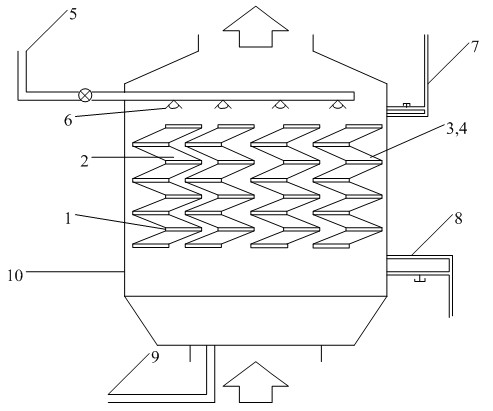

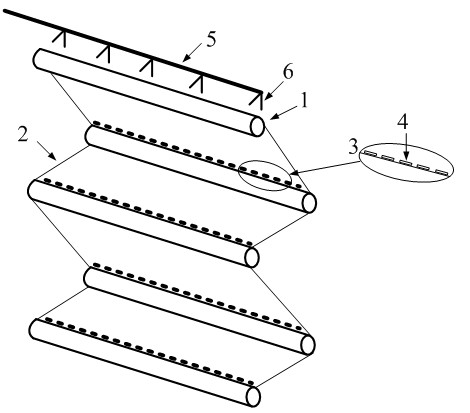

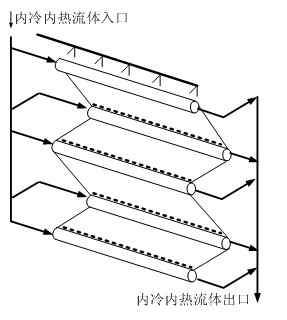

[0024] The housing 10 is equipped with a heat and mass transfer unit composed of a number of "zigzag" connected drop plates 2 and inner cooling and inner heat pipes 1, and a dehumidification solution inlet pipe 5 is provided on the upper left of the housing 10 for dehumidification. The solution is introduced and sprayed through the nozzle. The upper right of the housing 10 is provided with an internal cooling / internal heat source inlet main pipe 7 for the fluid of the cold and heat source, and the lower part is provided with an outlet pipe 8; the dehumidification solution inlet pipe 5 is provided Above the heat and mass transfer unit body, the liquid separator 6 is set on the dehumidification solution inlet pipe 5, and the dehumidification solution is evenly sprayed onto the drop plate 2 through the nozzle, and the dehumidification regeneration solution outlet pipe 9 is provided at the bottom of the shell 10 .

[0025] An overflow structure 3 is provided at the link between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com