Method for producing polyethylene

A polyethylene and product technology, applied in the field of polyolefin production, can solve problems such as sticking to the wall, achieve the effects of enhanced fluidity, lower material viscosity, and avoid sticking to the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

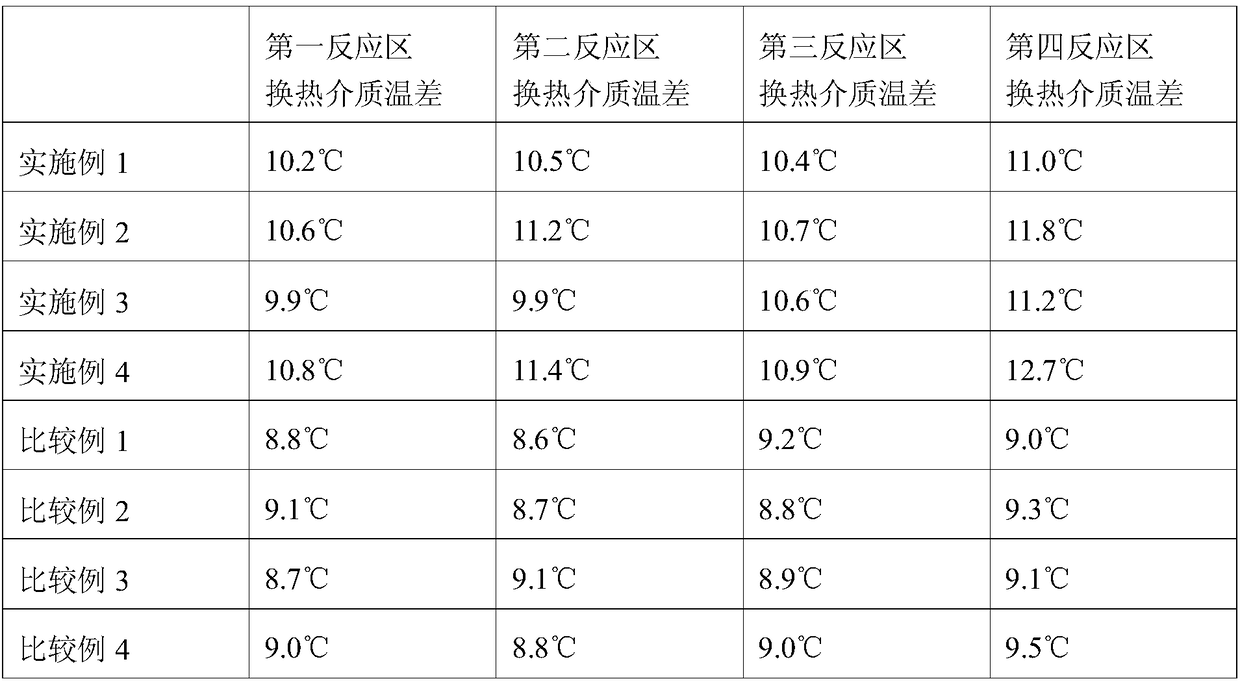

Examples

Embodiment 1

[0038] According to the method of the present invention, polyethylene is produced as follows:

[0039] A polyethylene tubular reactor with four reaction zones is used. The ethylene material is preheated by a reaction preheater, so that the temperature of the preheated reaction material reaches 170°C. The pressure of the polyethylene tubular reactor was set at 250MPa.

[0040] The reaction temperature of the first and second reaction zones of the polyethylene tubular reactor is set to 302°C, and the first-stage polymerization reaction is carried out in the first and second reaction zones to obtain the first polymerization product; the third and second The reaction temperature of the four reaction zones is set at 290° C., and the second-stage polymerization reaction is carried out in the third and fourth reaction zones to obtain the polymerization product polyethylene.

[0041] During the polymerization reaction, the heat exchange jacket of the reactor is fed with exchange wat...

Embodiment 2

[0043] Carry out the production of polyethylene according to the method for embodiment 1, difference is, carry out first-stage polymerization reaction at 307 ℃ in the first, second reaction zone, obtain the first polymerization product; In the 3rd, the 4th reaction zone at 285 The second-stage polymerization reaction is carried out at ℃ to obtain the polymerization product polyethylene.

Embodiment 3

[0045] The production of polyethylene was carried out according to the method of Example 1, the difference was that, during the first and second stages of polymerization, with the injection rate of 80g / h, oxygen was introduced into the reactor as a polymerization inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com