Centrifugal spray drying apparatus capable of preventing catalyst from adhering to walls

A centrifugal spray drying and centrifugal drying technology, used in spray evaporation, evaporator accessories, etc., can solve the problems of sticking to the inner wall of the drying tower, affecting the quality of catalyst powder, and difficulty in continuous operation, so as to avoid material sticking to the wall and disassembly. Easy assembly, maintenance and replacement, good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

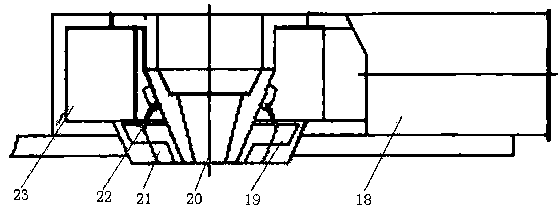

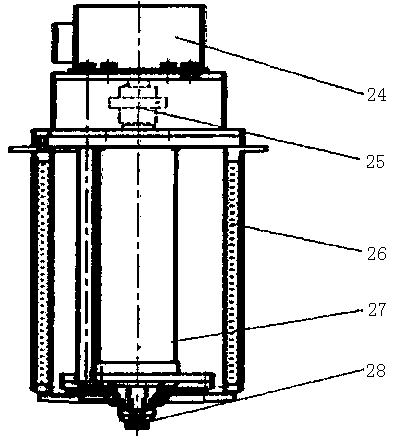

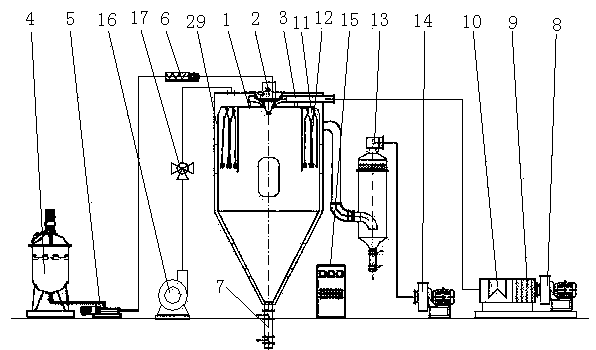

[0020] Example 1: like figure 1 — image 3, a centrifugal spray drying device that can prevent the catalyst from sticking to the wall, including a centrifugal drying tower 1 with a composite structure of a vertical upper cylinder and a lower cone, a feeding device, a heating device, a cooling feeder 7, a dust removal device and an intelligent The control box 15 is provided with a volute hot air distributor 3 and a frequency conversion centrifugal atomizer 2 in the middle of the tower top of the drying tower 1, and the nozzle of the frequency conversion centrifugal atomizer 2 passes through the cone 20 of the volute hot air distributor 3 Extends to the inside of the drying tower 1; the storage tank 4 of the feeding device is connected to the feed port of the frequency conversion centrifugal atomizer 2 through the feed pump 5, and the heating device is connected to the volute hot blast distributor 3 through a hot blast pipeline. The air inlet 18, the cooling feeder 7 is insta...

Embodiment 2

[0021] Example 2: like figure 1 , as an improvement of the present invention, the front end of the heating device is provided with an air filter 96, the air is filtered by the air filter 96 and sent to the electric heater 10 by the blower 8 to be heated to form hot air, and the hot air passes through the spiral The shell hot air distributor 3 enters the drying tower 1 in a spiral state after distribution, and exchanges heat and mass with the atomized material liquid sprayed from the nozzle of the frequency conversion centrifugal atomizer 2 . The coverage radius of the hot air is relatively large and the distribution is relatively uniform, which can fully and effectively combine with the atomized material liquid, and quickly evaporate the moisture in the atomized material liquid. The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0022] Example 3: like figure 1 , as an improvement of the present invention, a filter 6 is provided on the feed pipeline between the feed pump 5 and the frequency conversion centrifugal atomizer 2 to filter coarse fibers and large particles in the material to prevent The material blocks the distributor of the frequency conversion centrifugal atomizer 2 and the channel of the atomizing disc 28, so that the material forms a uniform atomized liquid when the material forms droplets and leaves the atomizing disc 28, and improves the uniformity of the catalyst powder or particles. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com