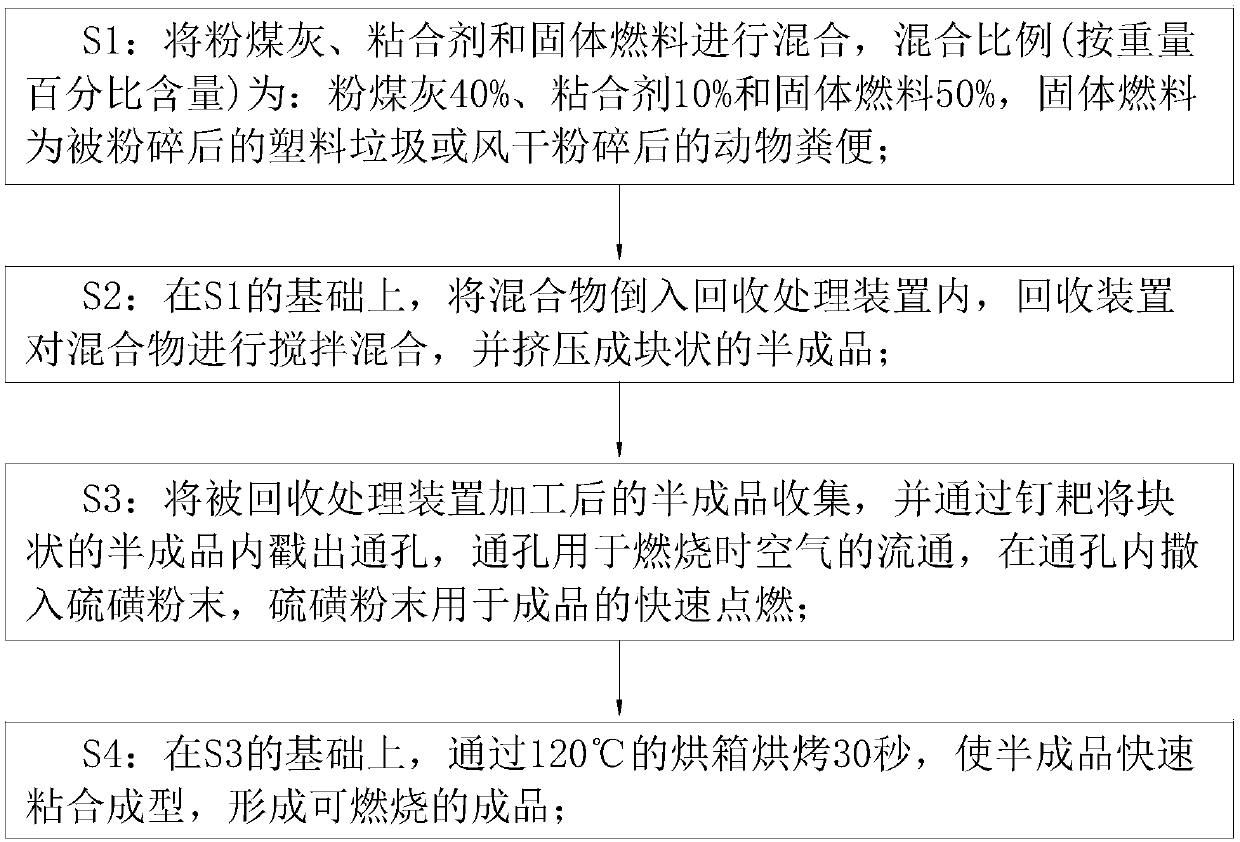

Recycling process of pulverized coal ash

A treatment process and technology for fly ash, applied in the petroleum industry, solid fuels, biofuels, etc., can solve the problems of insufficient combustion and difficult to ignite, and achieve the effect of improving the scraping effect, rapid ignition, and sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

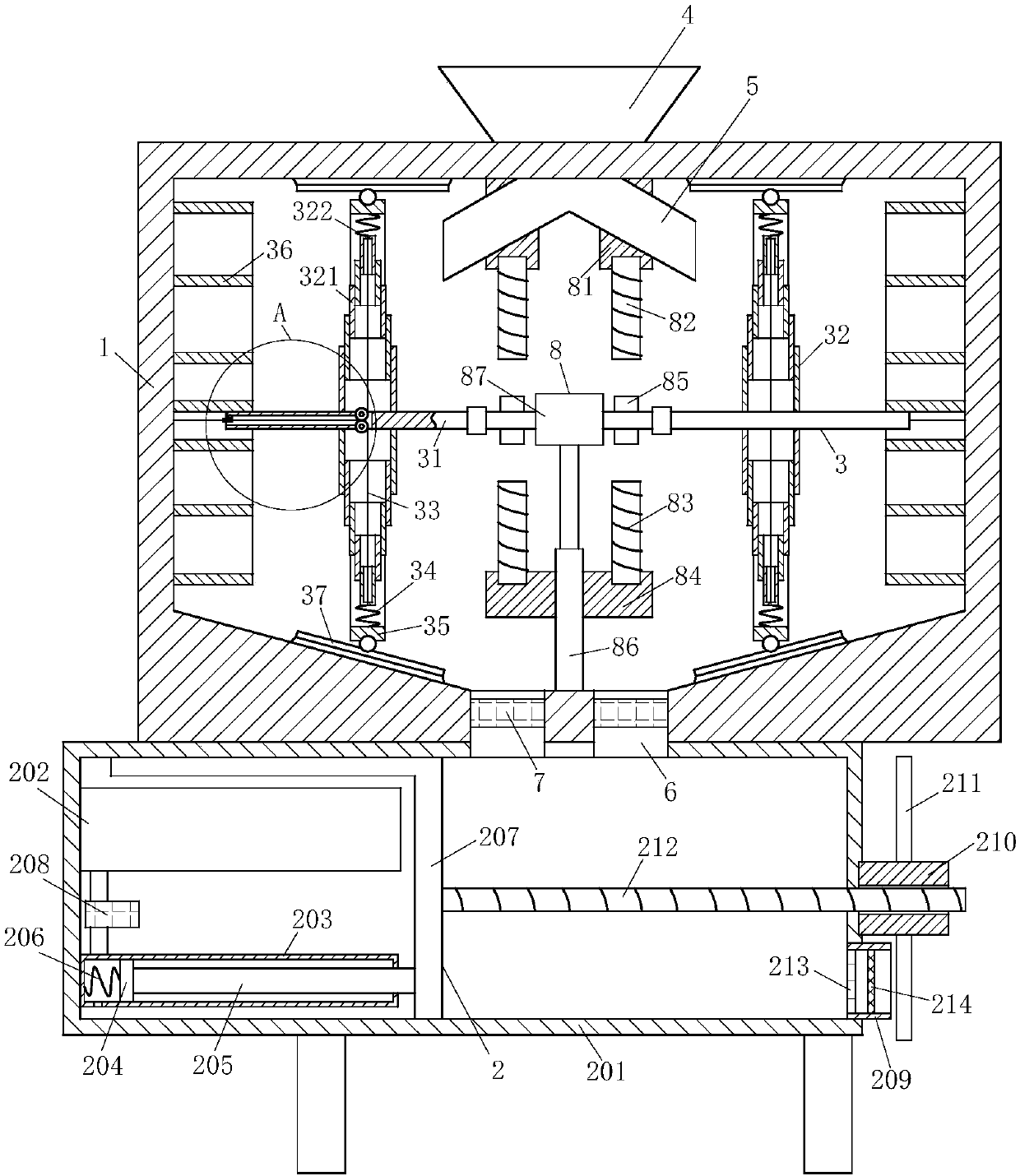

Method used

Image

Examples

Embodiment approach

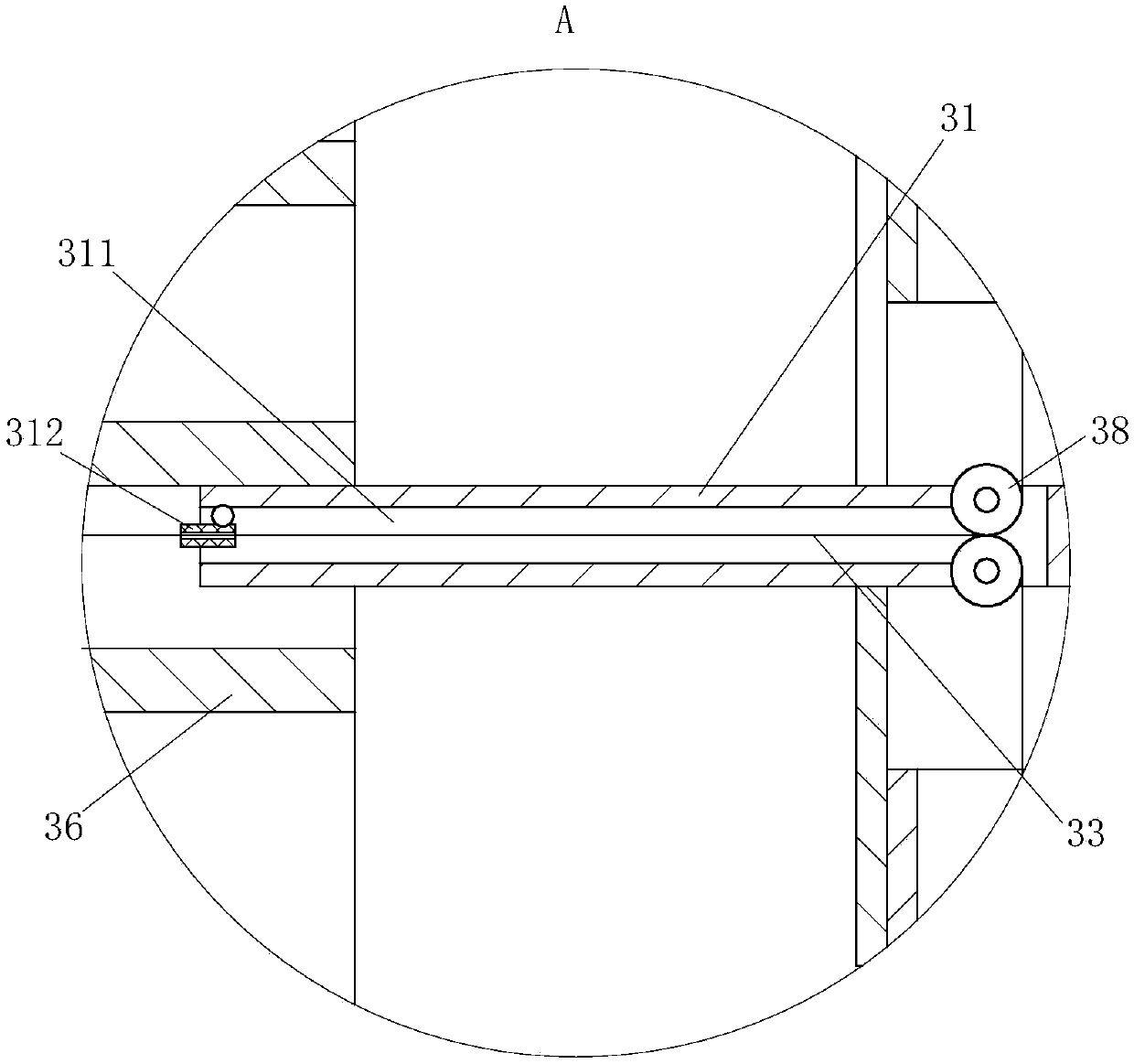

[0040] As an embodiment of the present invention, a sleeve 312 is hinged in the L-shaped through hole 311 , and a rope 33 slides through the sleeve 312 , and the sleeve 312 can swing freely under the drive of the rope 33 . When the rotating shaft 31 is shaking up and down, the angle of the rope 33 at the exit of the L-shaped through hole 311 of the rotating shaft 31 will change. At this time, the rope 33 can drive the sleeve 312 to rotate, thereby reducing the distance between the rope 33 and the exit of the L-shaped through hole 311. The friction at the place increases the service life of the rope 33.

[0041] As an embodiment of the present invention, the No. 1 wall scraping plate 36 includes an arc-shaped plate 361 and a No. 2 cylinder 362; the adjacent arc-shaped plates 361 are connected by the No. 2 cylinder 362, and a plurality of arc-shaped The connection between the plate 361 and a plurality of No. 2 cylinders 362 forms a complete No. 1 scraper plate 36; the No. 2 cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com