A kind of compound enzyme preparation and the technology for preparing paper pulp

A compound enzyme preparation and pulp technology, applied in papermaking, textiles and papermaking, using microorganisms/enzymatic cellulose treatment, etc., can solve the problems of long cycle, achieve short cycle, improve bleachability, and improve bleachability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

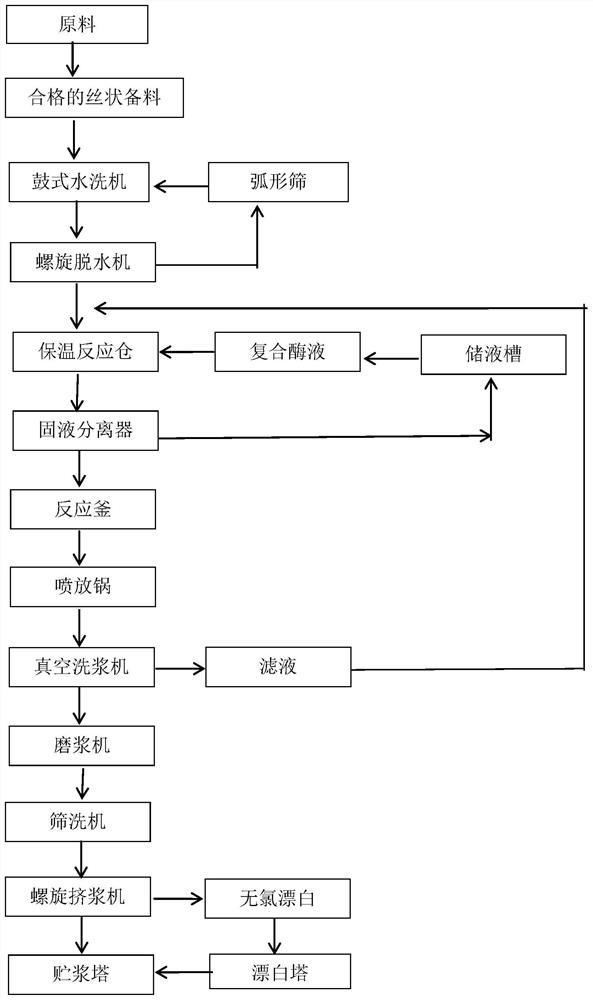

Image

Examples

Embodiment 1

[0048] Step 1, the poplar wood material is prepared by equipment, and the filamentous material suitable for pulping is obtained through the processes of peeling, cutting, chipping and cooking;

[0049] Step 2: After the material is washed by a drum washing machine and dehydrated by a spiral dehydrator, it is moved into the heat preservation reaction chamber through a conveyor belt, and the compound enzyme preparation solution is added according to the material ratio of 1:4, and the pH is adjusted to 5.5, and the temperature in the tank is kept at 60°C. 120min; after the reaction, the liquid was recovered to the liquid storage tank; the compound enzyme solution was prepared by dissolving the industrial enzyme powder preparation in the buffer solution. The preparation process of the compound enzyme preparation solution was as follows: 10 parts of laccase and 15 parts of xylanase , 3 parts of pectinase, and 1 part of mannanase were weighed respectively for laccase enzyme powder, x...

Embodiment 2

[0054] Step 1, the poplar wood material is prepared by equipment, and the filamentous material suitable for pulping is obtained through the processes of peeling, cutting, chipping and cooking;

[0055] Step 2: After the material is washed by a drum washing machine and dehydrated by a screw dehydrator, it is moved into the heat preservation reaction chamber through a conveyor belt, and the compound enzyme preparation solution is added according to the material ratio of 1:3, and the pH is adjusted to 5.7, and the temperature in the tank is maintained at 63°C. 135min; after the reaction, the liquid was recovered to the liquid storage tank; the compound enzyme solution was prepared by dissolving the industrialized enzyme powder preparation in the buffer solution. The preparation process of the compound enzyme preparation solution was as follows: 20 parts of laccase and 10 parts of xylanase , 5 parts of pectinase, and 1 part of mannanase weighed respectively laccase enzyme powder, x...

Embodiment 3

[0060] Step 1, the poplar wood material is prepared by equipment, and the filamentous material suitable for pulping is obtained through the processes of peeling, cutting, chipping and cooking;

[0061] Step 2, after the material is washed by a drum washing machine and dehydrated by a spiral dehydrator, it is moved into the heat preservation reaction chamber through a conveyor belt, and the compound enzyme preparation solution is added according to the material ratio of 1:4, and the pH is adjusted to 6.0, and the temperature in the tank is maintained at 65°C. 150min; after the reaction, the liquid was recovered to the liquid storage tank; the compound enzyme solution was prepared by dissolving the industrialized enzyme powder preparation in the buffer solution. The preparation process of the compound enzyme preparation solution was as follows: 15 parts of laccase and 13 parts of xylanase , 4 parts of pectinase, and 1 part of mannanase weighed respectively laccase enzyme powder, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com