Desulfurization and purification method and equipment for unpowered sintering machine by using two-step method

A sintering machine, two-step technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as unstable operation, system corrosion, low desulfurization rate, etc. The effect of low and high desulfurization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

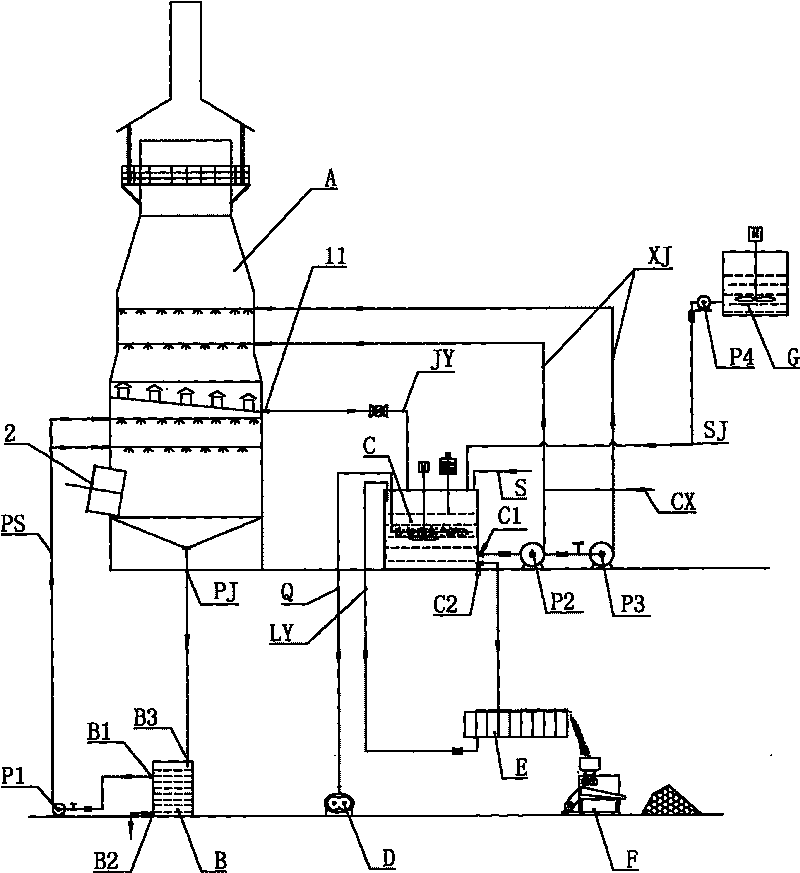

[0025] see Figure 1 ~ Figure 4 , the present invention's two-step non-assisted sintering machine desulfurization purification device, including desulfurization reaction tower A, dust removal circulation system, desulfurization circulation system.

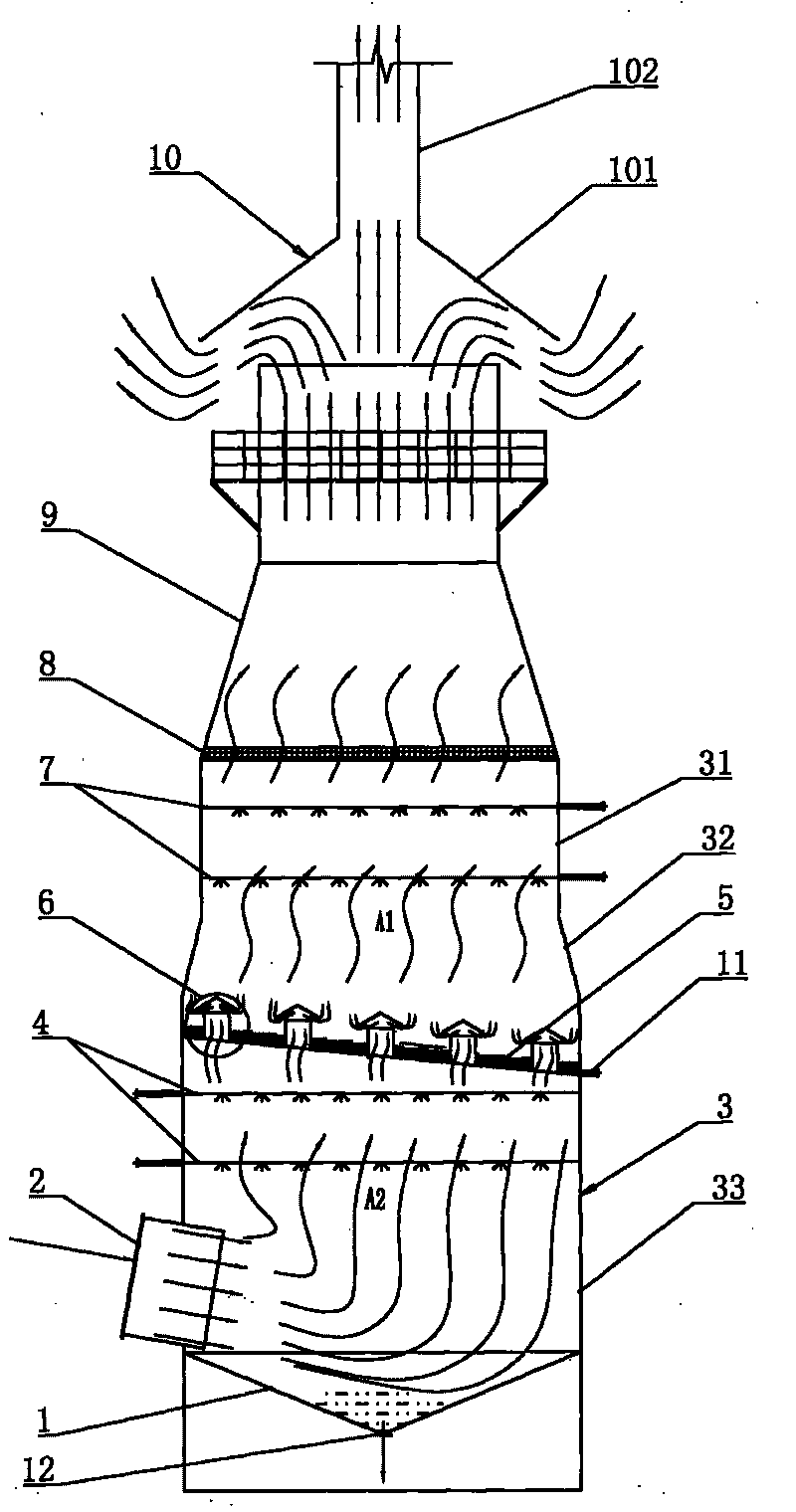

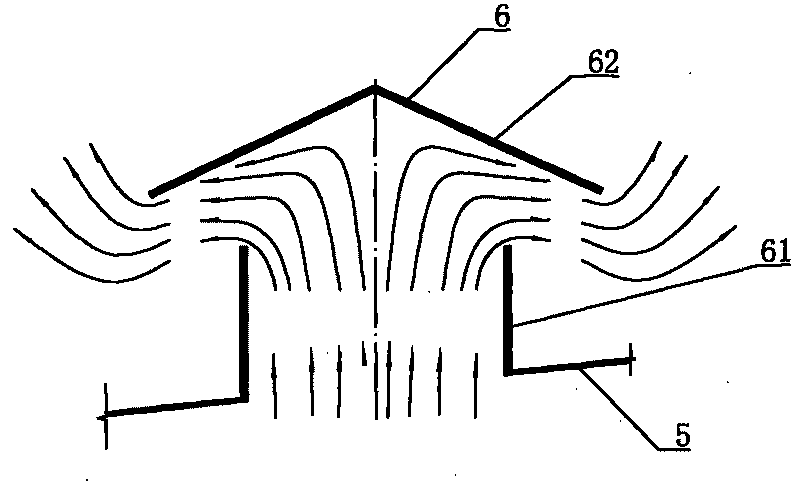

[0026] The structure of described desulfurization tower A (see Figure 2 ~ Figure 4 ) is: the upper end of the cylindrical tower body 3 is connected with a conical discharge port 9 with a small diameter at the upper end, and a cap type cover body 10 is installed above the conical discharge port 9 . In the middle of the tower body 3, there is an obliquely arranged bubble cap bottom plate 5, which divides the tower body 3 into upper and lower parts, and a plurality of bubble cap type flue gas risers 6 are arranged on the bubble cap bottom plate 5. The upper and lower regions of the blister bottom plate 5 are respectively the desulfurization reaction zone A1 and the washing and dust removal zone A2, and the desulfurization solution s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com