Sealing device for preventing cold air from entering preheater at tail of rotary kiln

A technology of sealing device and rotary kiln, which is applied in the direction of rotary drum furnace, lighting and heating equipment, furnace, etc., can solve the problems of poor sealing, achieve the effects of reducing coal consumption, improving flexibility and reducing system resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013]The present invention will be described in detail in connection with the accompanying drawings and examples in conjunction with the drawings and examples.

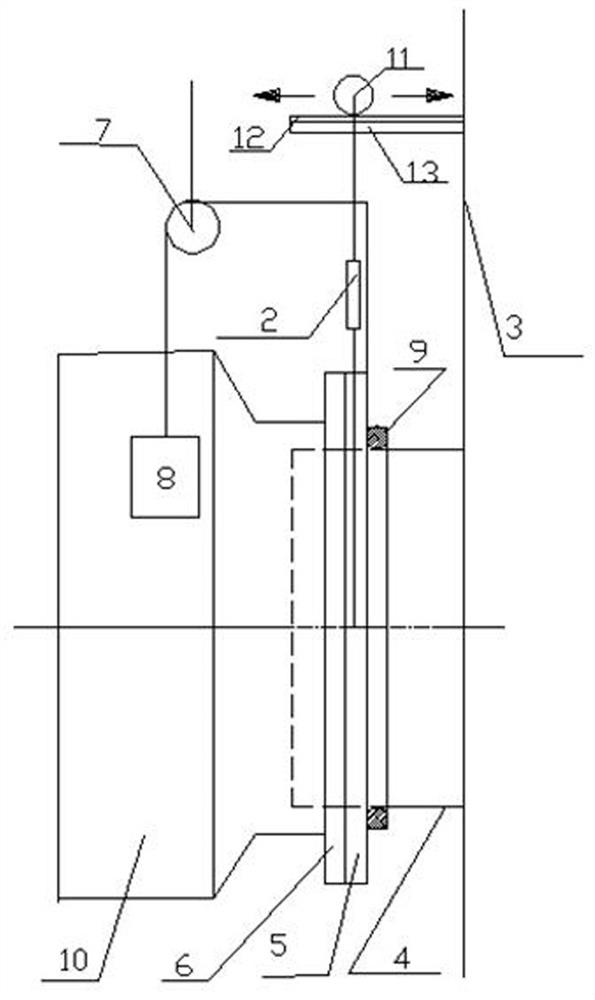

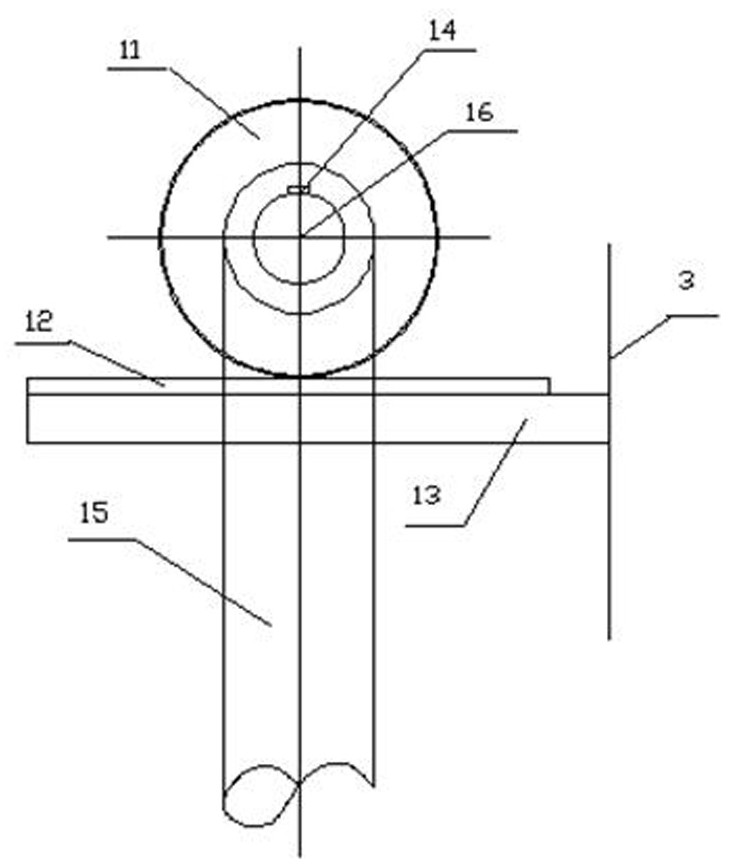

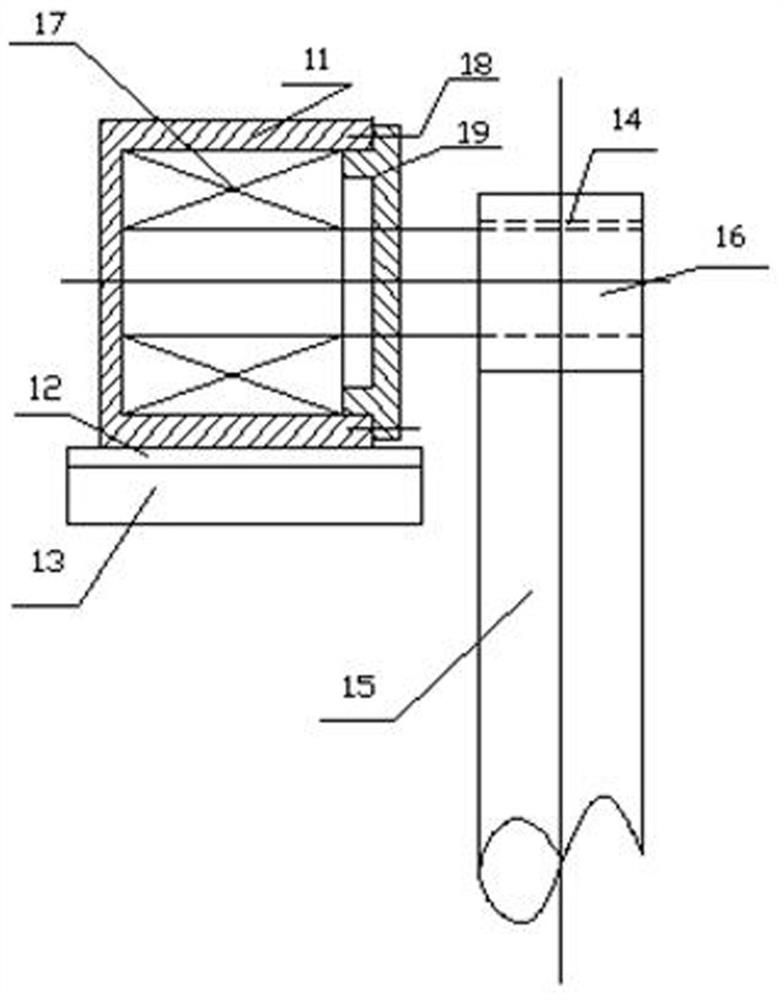

[0014]A rotary kiln kiln tail anti-cold wind enters a preheater sealing device, such asfigure 1 As shown, the horizontal orbit 12 and the track base 13 homogenerate, the roller 11 is a cylinder, and when the roller 11 rolls back in the horizontal rail 12, the center of the roller 11 can be maintained. Will not change. The kiln tail cigarette chamber fixing sleeve 4 is fixed to the kiln tail tunnel 3, the center line of the kiln tail tobacco compartment fixing sleeve 4 is coincident with the centerline of the rotary kiln cylinder 10, the ring seal 9 seals the fixing friction ring 5 and the kiln tail The smoke room fixes the gap between the sleeve 4 to prevent the gap. The roller shaft 16 is rigidly attached to the screw buckle link 15, and then the fixing friction ring 5 is rigidly attached, and the fixing friction ring is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com