Cement raw meal vertical pipe rotary spray preheater and preheating and decomposing system

A cement raw meal and preheater technology, which is applied in cement production, preheating cost, clinker production, etc., can solve the problems of increasing the moving route of material gas, affecting separation efficiency, and large system resistance, and achieves extended rotation separation. time, improve separation efficiency, and the effect of smooth motion path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

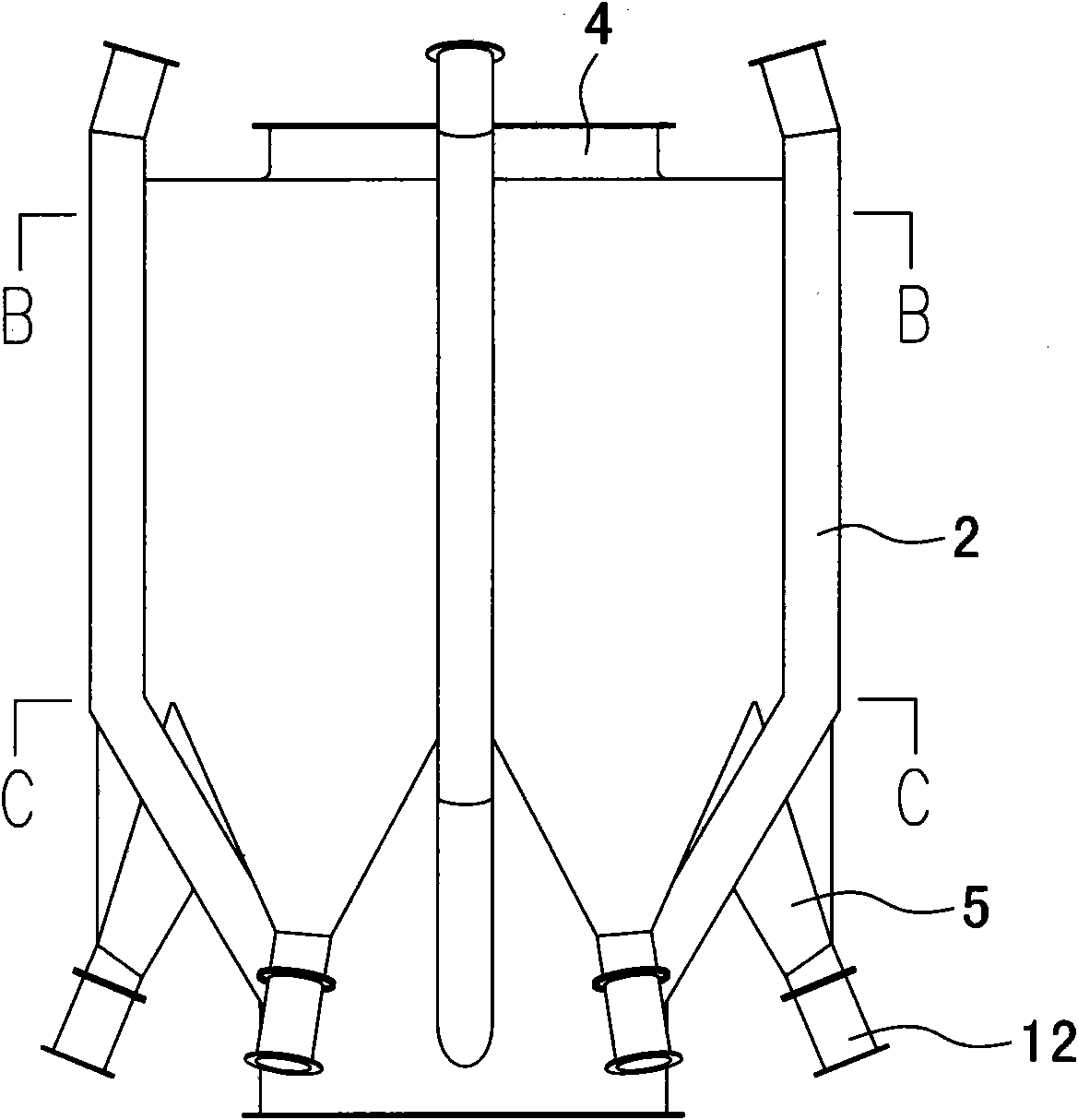

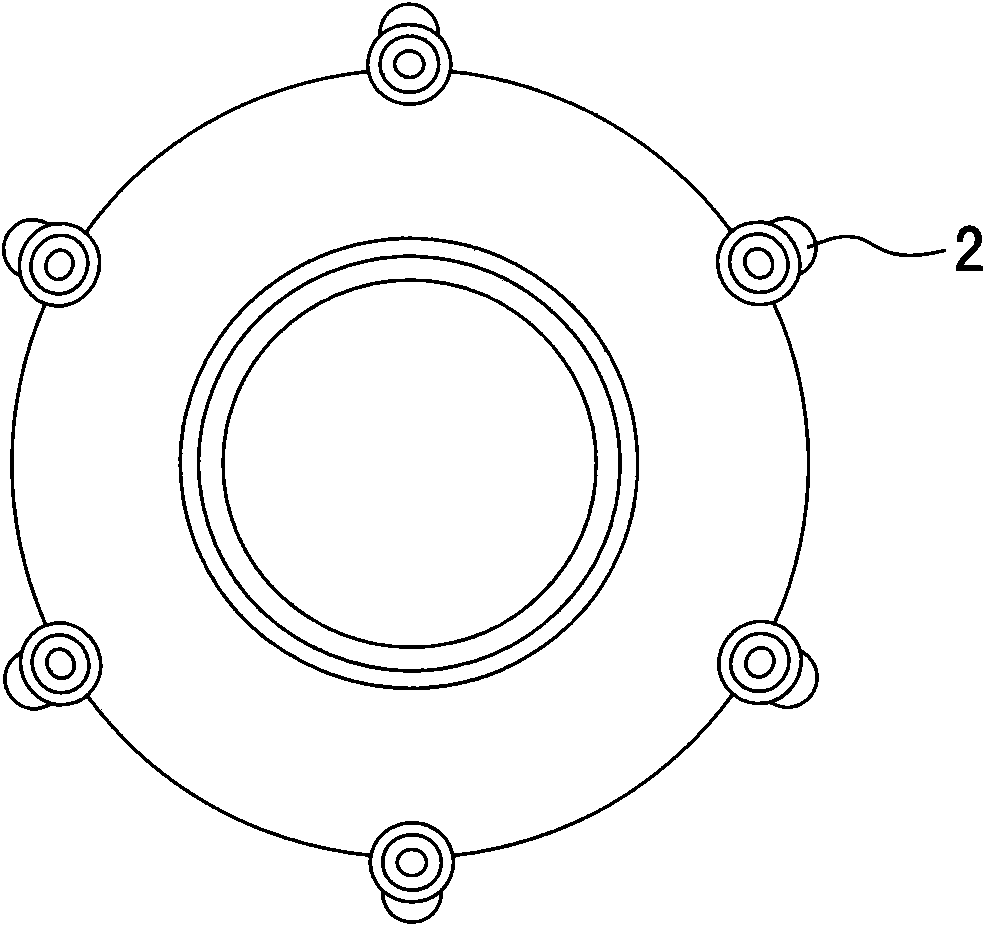

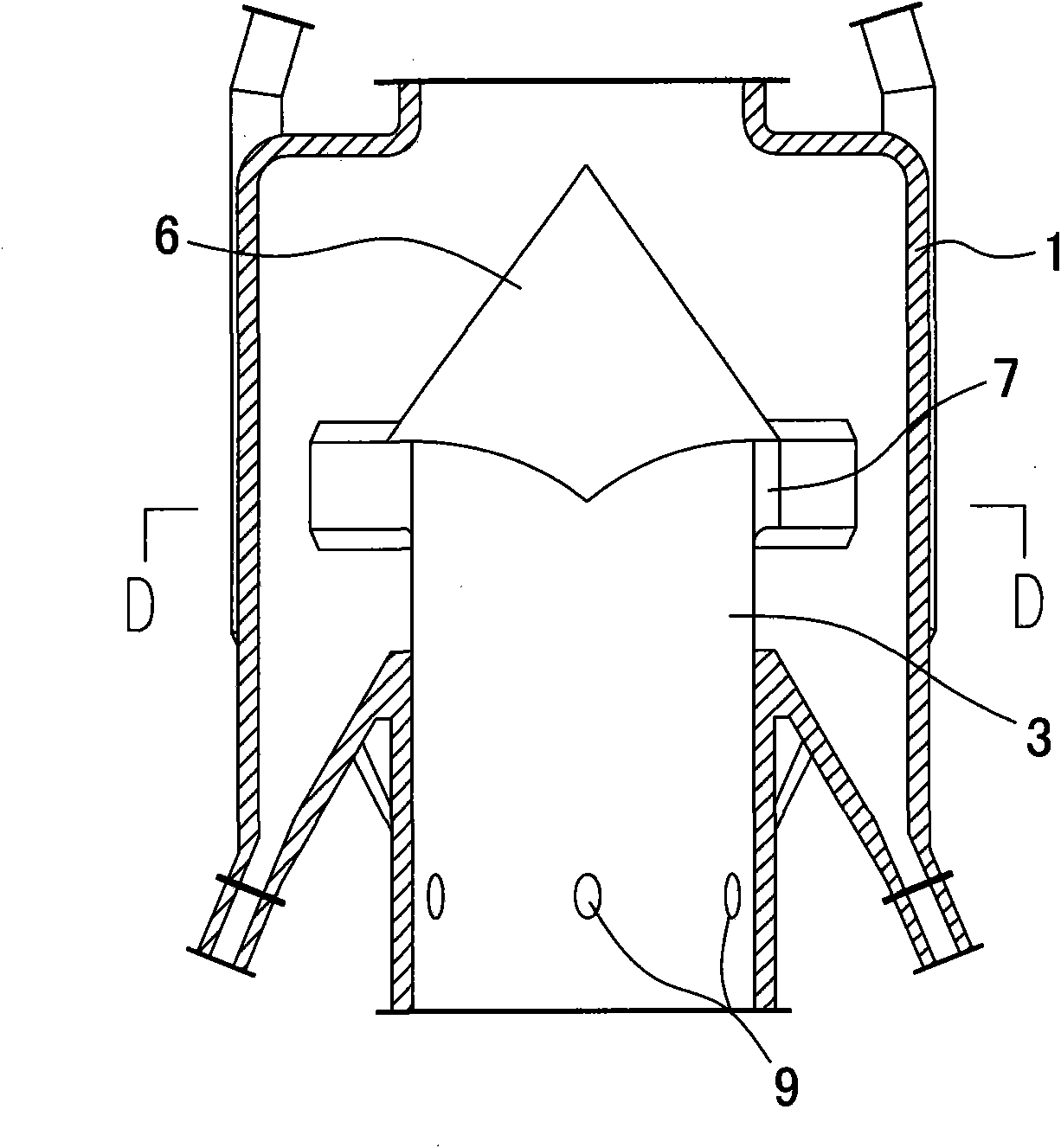

[0037] see Figure 1~6 As shown, a cement raw meal standpipe rotary spray preheater includes a rotary spray cylinder body 1, a feed pipe 2 and a standpipe 3 coaxially arranged in the rotary spray cylinder body, and the bottom of the standpipe protrudes from the rotary spray cylinder. Outside the cylinder; the top of the rotary spray cylinder 1 is provided with an air outlet 4, and its bottom is evenly distributed with 6 collecting hoppers 5, and the bottom of each collecting hopper is provided with a discharge port 12;

[0038]The top of the standpipe 3 is provided with a guide cone 6, and the sidewall of the standpipe below the guide cone is evenly distributed with a plurality of swirl nozzles 7 in the circumferential direction, and each swirl nozzle 7 is provided with a matching curved surface cyclone guide plate 8, and the standpipe The bottom is fixedly connected with the collection hopper, and the lower side wall of the standpipe is also circumferentially evenly distribut...

Embodiment 2

[0051] see Figure 10 As shown, a cement raw meal powder preheating decomposition system is composed of 8 cement raw meal standpipe rotary jet preheaters connected in series vertically. The air outlet of the upper stage preheater is connected with the feed pipe of the next stage preheater. The axis of each preheater is on the same vertical line. There is a decomposition furnace 10 in between.

[0052] The above-mentioned cement raw meal vertical pipe rotary jet preheater is the same as that of Embodiment 1.

[0053] Taking the preheating and decomposition system of the standpipe rotary spray preheater that produces 105 tons (2500t / d) of cement clinker per hour as an example, the 8-stage preheating decomposition system composed of the above-mentioned 8 standpipe rotary spray preheaters vertically connected in series is adopted. After the system, the system resistance is lower than 3000pa, and the exhaust gas temperature can be controlled at about 200°C. Compared with the exis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com