Device for evaporation pyrolysis

A kind of evaporation heat, decent technology, applied in evaporation, ammonia preparation/separation, heating water/sewage treatment, etc., can solve the limitation of large-scale popularization and use of urea solution pyrolysis, insufficient urea solution evaporation and pyrolysis, affecting SCR system Denitration efficiency and other issues, to achieve the effect of improving the efficiency of evaporation and pyrolysis, the structure is simple and reliable, and the uniformity of the flow field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0040] Specific Example 1

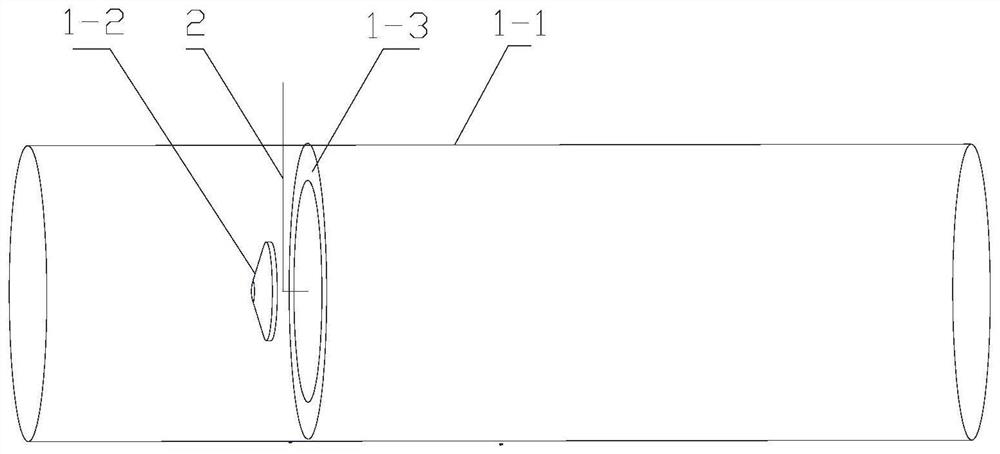

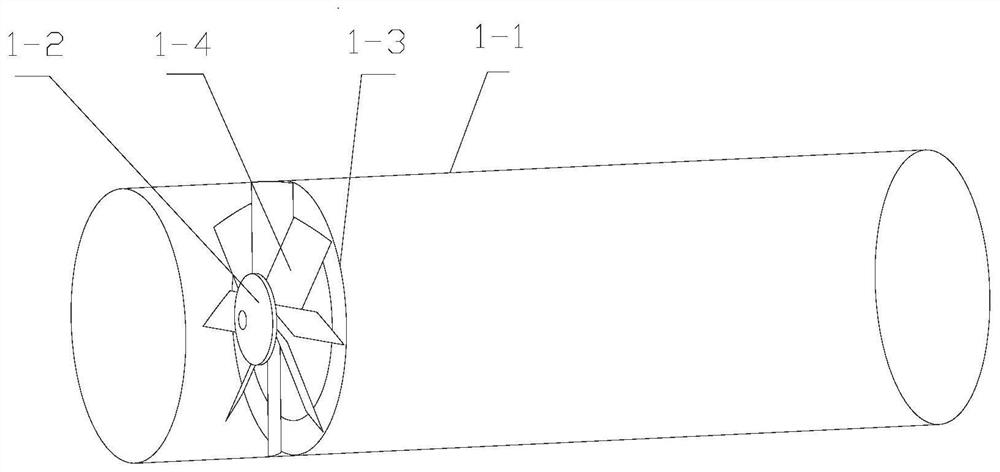

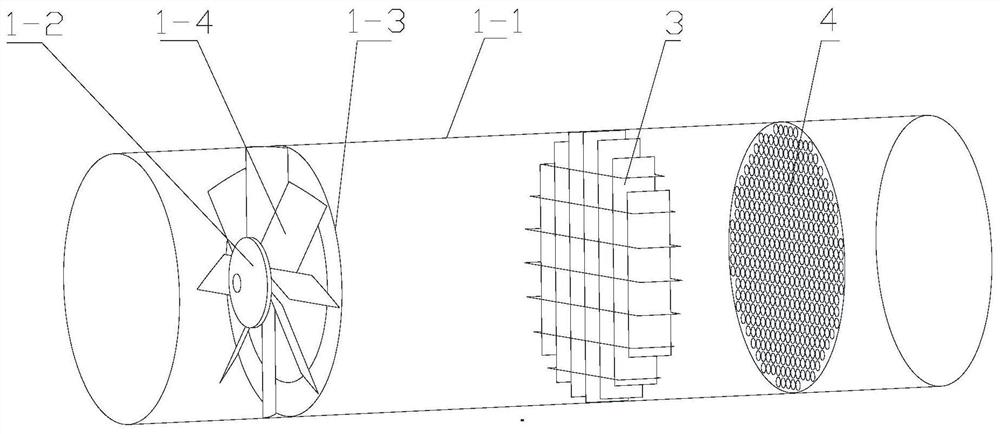

[0041] The following combined with the drawing of the distributed energy denitration system of a certain power plant gas internal combustion engine as an example, and the present invention will be further described.

[0042] In this first embodiment, the development project is studied in the use of SCR method flue gas denitration process, and the reducing agent is urea, and ammonia gas is prepared by the urea solution thermolysulofer, so that the system can achieve a nitrogen oxide (NOx) emission indicator below 30 mg / The purpose of NM3. High efficiency evaporation pyrolysis device and denitration system such as Figure 4 As shown: The gas internal combustion engine generates a flue gas temperature of 370 to 550 ° C, up to 600 ° C, and the power generation force is 4.4mW, and the amount of flue gas is from 100% in the gas internal combustion engine load. 19500 nm3 / h. At the state, the NOx is 350 mg / nm3 under the dry base 5% o2, and the flue gas ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com