Preparation method of high-heat-conductivity veneer graphene impregnated modified wood

A graphene, high thermal conductivity technology, applied in wood impregnation, wood impregnation, pressure impregnation, etc., can solve problems such as low thermal conductivity, achieve uniform heat dissipation, shorten heat transfer time, and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

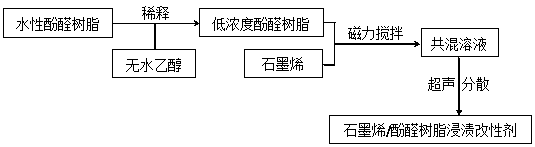

[0023] Example 1: Preparation of graphene / phenolic resin impregnated modified veneer

[0024] Due to the high solid content of water-soluble phenolic resin, it is not easy to impregnate and will solidify on the equipment, which will cause difficulties in equipment cleaning. It needs to be diluted with absolute ethanol to a solid content of 15% to 30%. Mix the diluted phenolic resin with graphene in an amount of 1% to 3% to obtain a blend solution, where the added amount is defined as: the mass ratio (solid content) of the mixed phenolic resin is 1% to 3%; The blended solution was magnetically stirred for 10 to 30 minutes, and then ultrasonically dispersed with an ultrasonic breaker (ultrasonic power of 80w, ultrasonic time of 20 to 30min), and the graphene / phenolic resin impregnated modifier was obtained.

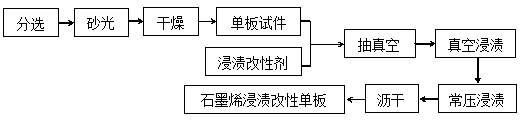

[0025] Sorting the fast-growing poplar veneer to remove the wormy and moldy boards, so that the impregnating agent can better enter the wood cells. Sand the surface and si...

Embodiment 2

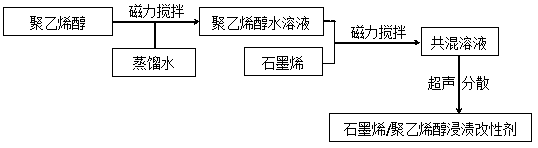

[0026] Example 2: Preparation of graphene / polyvinyl alcohol impregnated modified veneer

[0027] Pour polyvinyl alcohol (type p1788, degree of alcoholysis: 87.0-89.0% (mol / mol)) into the water bath slowly, and keep stirring with a glass rod, fully contact with the distilled water in the pot to avoid condensation, and finally Magnetic stirring for 45-60 min to obtain an aqueous solution of polyvinyl alcohol with a mass concentration of 5-15%; mixing the aqueous solution of polyvinyl alcohol with graphene in an addition amount of 1%-3% to obtain a blended solution, where the addition amount is defined as: 1% ~ 3% of the solute mass of the mixed polyvinyl alcohol aqueous solution; put the blended solution into an ultrasonic breaker for ultrasonic dispersion (ultrasonic power is 80w, ultrasonic time is 20 ~ 30 min), and the graphene / polymer Vinyl alcohol impregnation modifier.

[0028] Sorting the fast-growing poplar veneer to remove the wormy and moldy boards, so that the impreg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com