Natural circulation phase change heating storage tank

A technology of natural circulation and oil storage tanks, which is applied to tank cars, transport passenger cars, railway car body parts, etc., can solve the problems of large medium loss, high energy consumption, and easy fouling, so as to improve heat exchange efficiency and prolong heat exchange Time, the effect of expanding the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

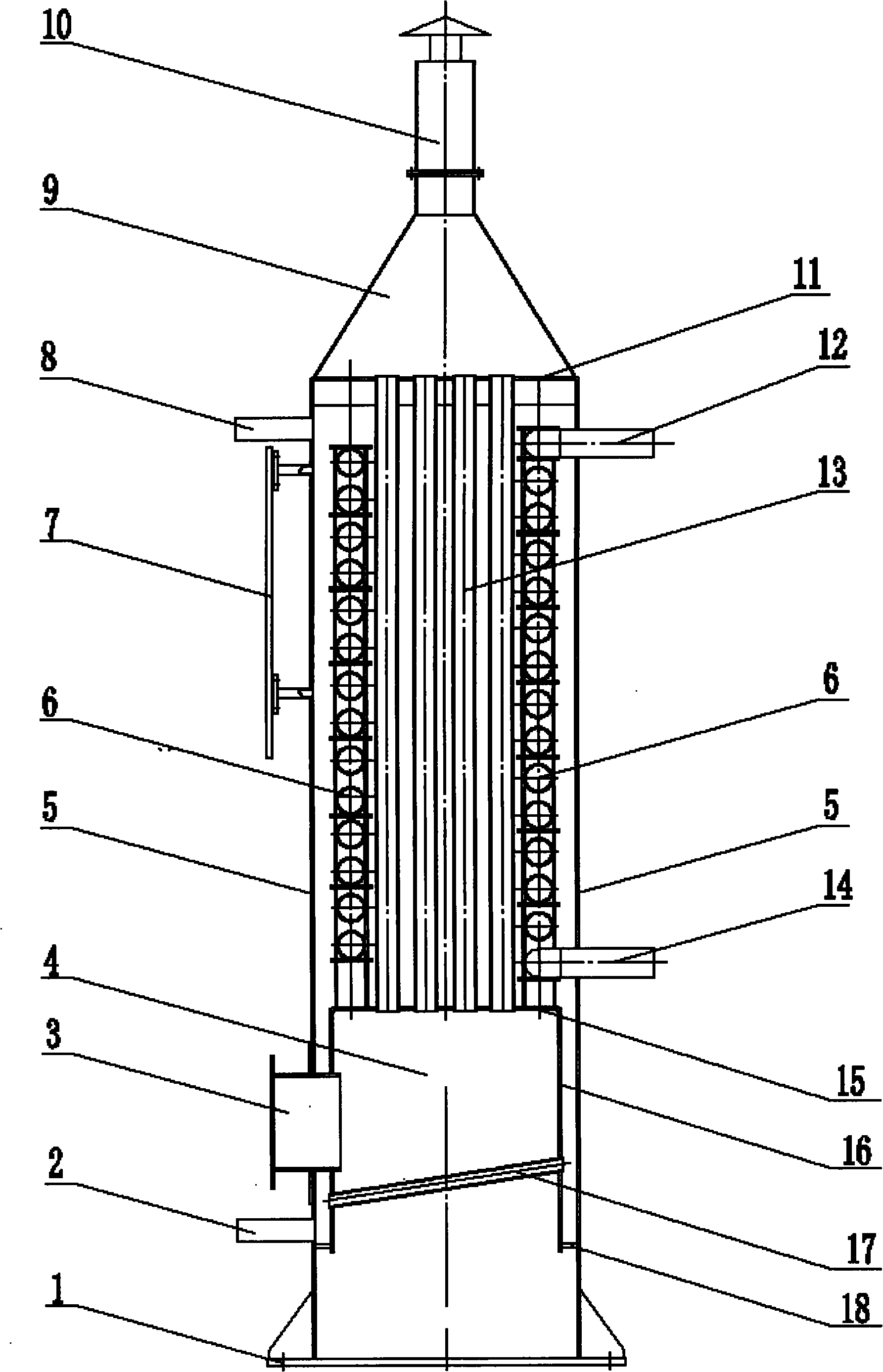

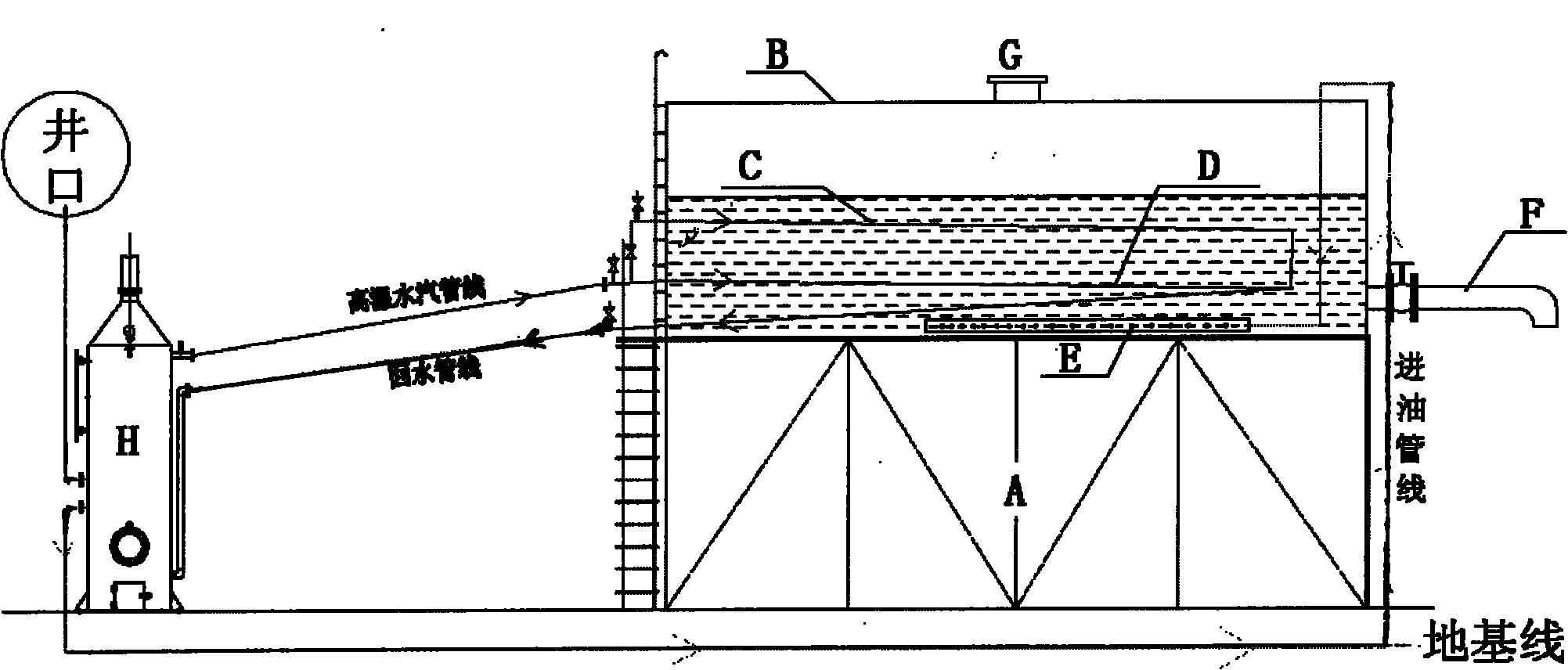

[0015] Embodiment 1: in combination with Figure 1-2 , to further describe the present invention:

[0016] The present invention is mainly composed of a phase change heating furnace H, an oil storage tank and a pipeline system. The phase change heating furnace is connected to the oil storage tank through the pipeline system; the oil storage tank has a normal pressure tank or a pressure separation tank Two forms; the pipeline system is composed of crude oil pipelines, gas pipelines, water vapor circulation pipelines, and valves. The crude oil pipelines and gas pipelines are laid under the foundation line; The water vapor enters the tank pipeline, and the lower part is the condensate return pipeline.

[0017] Among them, the atmospheric tank is a horizontal cuboid, consisting of a tank base A, a tank body B, an upper heat exchanger C, a lower heat exchanger D, a crude oil diffuser E, an oil discharge port F, and a breathing port G, and the tank body B is fixed. On the tank bas...

Embodiment 2

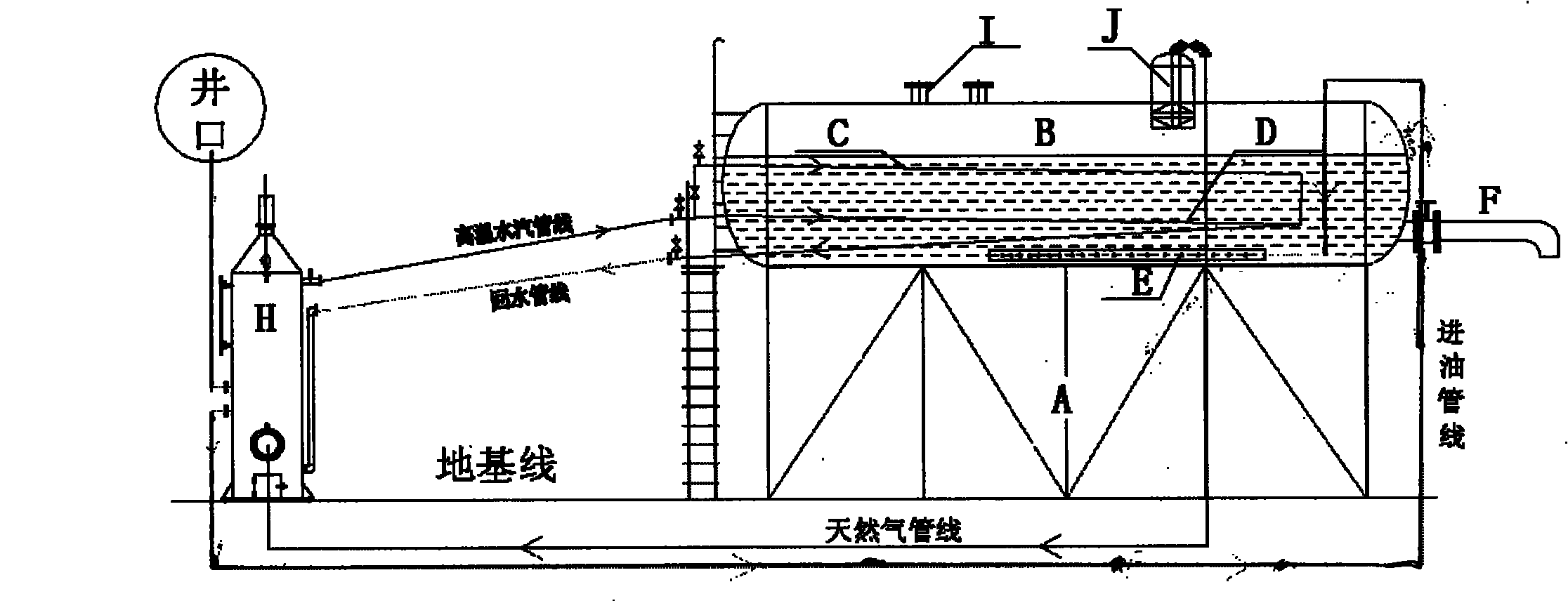

[0022] Embodiment 2: in combination with image 3 , to further describe the present invention:

[0023] Another pressure-bearing separation tank is a horizontal cylinder, which consists of a tank base A, a tank body B, an upper heat exchanger C, a lower heat exchanger D, a crude oil diffuser E, an oil discharge port F, a safety valve I and a gas distributor. The tank body B is fixed on the tank seat A, the upper heat exchanger C, the lower heat exchanger D, and the crude oil diffuser E are respectively fixed at the bottom of the tank body, and the safety valve I and the gas distribution bag J are placed in the tank top of the body.

[0024] The advantages of the present invention are as follows:

[0025] 1. Safe and reliable, the distance between the heating furnace and the oil storage tank is more than 15 meters, in line with the safety fire regulations of GB50183-2004 "Code for Fire Protection of Oil and Gas Engineering Design"; equipped with a thermostatic control valve, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com