Manufacturing method for PVC straight-through pipe and PVC straight-opening reducer tee joint

A technology of reducing tees and manufacturing methods, which is applied in the direction of pipes/pipe joints/fittings, pipes, branch pipelines, etc., and can solve problems such as inability to form welds, limit the application of PVC pipes, and unrealized hot-melt welding technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066](Example 1, the formula and preparation process for preparing extruded PVC pipes in parts by weight)

[0067] In addition to ensuring the molding (extrusion or injection molding) of PVC pipes in the formulation design of hot-melt welded PVC pipes, the subsequent welding molding should also be fully considered. The material has been fully plasticized (gelled) by the PVC pipe molding process under the action of heat and mechanical shearing force, forming a network structure in which molecular chains are intertwined. In the subsequent hot-melt welding, enough heat energy must be obtained to fully melt the end of the PVC pipe and untangle the molecular chains. Therefore, the process temperature during hot-melt welding is higher than the forming temperature of the first PVC pipe. Generally around 230°C, which requires the design of a formula with better thermal stability, and the amount of stabilizer is more than 30% higher than that of normal tubes. PVC-U is a highly polar ...

Embodiment 2

[0070] (Example 2, the formula for preparing injection-molded PVC tubing and its preparation process)

[0071] A formula in parts by weight for preparing injection-molded PVC tubular objects in this embodiment is as follows: 100 parts of PVC resin, 0.4 to 4.5 parts of stabilizer, 0.2 to 0.5 parts of oxidized polyethylene wax, 0 to 0.5 parts of polyethylene wax, 0-0.6 parts of paraffin, 0-0.5 parts of stearic acid, 0.5-2.0 parts of calcium stearate, 0-3.0 parts of acrylate ACR, 0-5.0 parts of chlorinated polyethylene CPE, 0-4.0 parts of MBS additives, 1.0 parts of calcium carbonate ~15.0 parts, 0.2~3.0 parts of titanium dioxide, appropriate amount of pigments, the pigments in this embodiment are as follows: 0.2~2.0 parts of titanium dioxide, 0~0.1 parts of phthalocyanine blue, 0~0.1 parts of carbon black. Among them, the MBS additive is a terpolymer of methyl methacrylate, butadiene and styrene, which is one of the most important impact modifiers for PVC.

[0072] The preparat...

Embodiment 3

[0073] (Example 3, manufacturing method of heat-melt welded PVC pipe fittings)

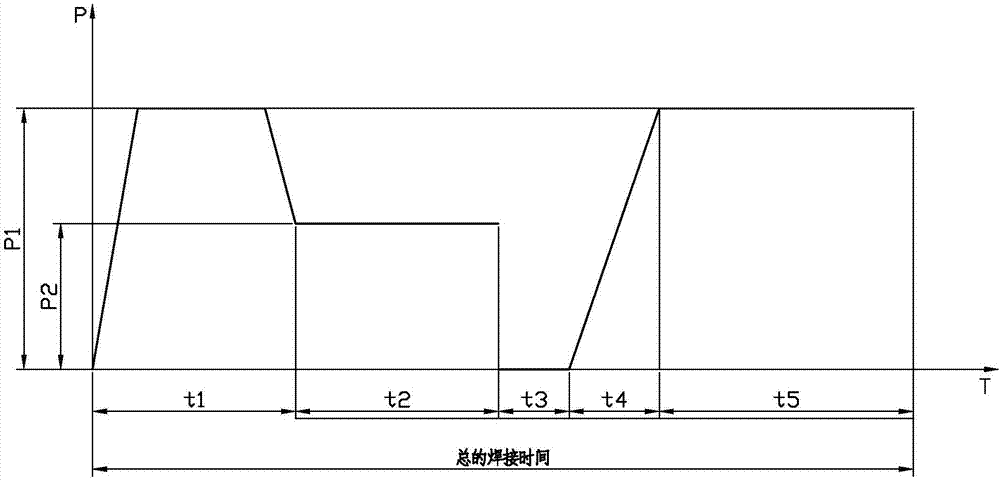

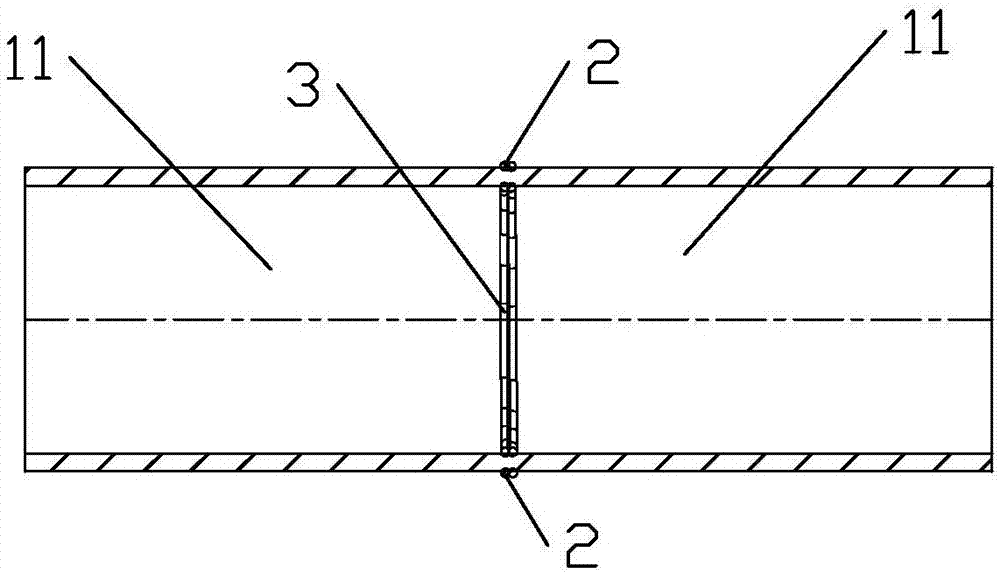

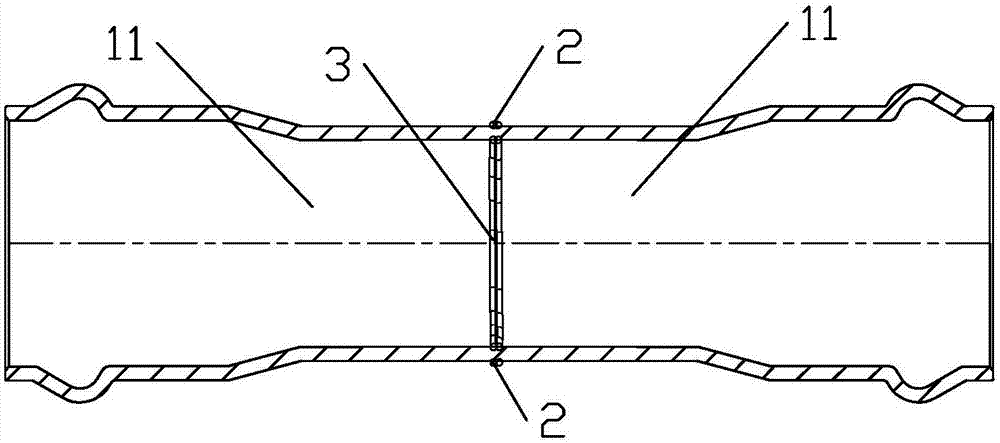

[0074] See figure 1 , the manufacturing method of the heat-melt welded PVC pipe fitting of the present embodiment comprises the following steps:

[0075] ① Select the corresponding extrusion-molded PVC tubular obtained in Example 1 or the injection-molded PVC tubular obtained in Example 2 according to the product specifications, and use a multi-angle pipe sawing machine to cut the PVC tubular into required lengths and angles ;

[0076] ②Place the cut PVC pipe on the welding machine fixture and fix it;

[0077] ③Treat the end surfaces to be welded of the pipe ends of the two PVC pipes to be smooth and smooth to meet the welding requirements and suitable for anastomosis;

[0078] ④ Close the end faces and check the alignment. The misalignment of the two end faces to be welded does not exceed 10% of the wall thickness. Otherwise, use the clamping force of the fixture to adjust and reprocess until ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com