Composite positive electrode of rapidly-activated thermal battery and manufacturing method thereof

A composite cathode and thermal battery technology, applied to the electrodes of primary batteries, battery electrodes, circuits, etc., can solve the problem of increasing activation time, and achieve the effect of reducing activation time, reducing the intermediate process of heat transfer, and shortening activation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

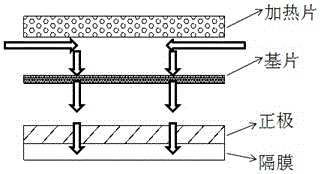

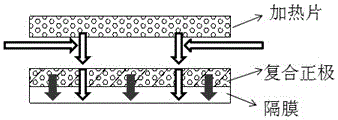

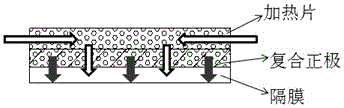

[0022] A preparation method for rapidly activating a thermal battery composite positive electrode, the method comprising: physically mixing the pre-coated thermal battery positive electrode material and heating powder in proportion to uniformity, and adopting a powder compaction method to form, and inserting a wire mesh into the sheet as a The supporting skeleton prevents deformation and forms a network of technical filaments to enhance conductivity.

[0023] Preferably, the above-mentioned wire mesh needs to be flattened and embedded in the positive electrode layer, the diameter of the wire mesh is 60%-90% of the sheet diameter, and the wire is made of a material with good conductivity and corrosion resistance, such as copper, nickel, silver, etc.

[0024] Preferably, when the mixing ratio of the heating powder in the composite positive electrode is more than 20%, a combustion type positive electrode can be formed, and the separate molding of the heating sheet can be canceled ...

Embodiment 1

[0025] Embodiment 1: A composite positive electrode for fast activation thermal battery, its composition percentage is: 45% positive electrode material FeS 2 , 55% heating powder Fe-KClO 4 , and its preparation method is as follows: the FeS 2 The molten salt electrolyte is used for coating pretreatment, and the heating powder (Fe-KClO 4 ) mixed at room temperature at a ratio of 55% to obtain a composite positive electrode material; place the wire mesh at the bottom of the mold, pour the weighed composite positive electrode into it, spread it out, pour it into a weighed diaphragm, spread it out, and press Next filming. Compared with conventional assembly, the activation time of the positive electrode battery prepared in Example 1 can be reduced by 29%, and the activation time can reach 85ms.

Embodiment 2

[0026] Embodiment 2: A composite positive electrode for fast activation thermal battery, its composition percentage is: 85% positive electrode material CoS 2 , 15% heating powder Fe-KClO 4 , and its preparation method is as follows: the CoS 2 The molten salt electrolyte is used for coating pretreatment, and the heating powder (Fe-KClO 4 ) mixed at room temperature at a ratio of 15% to obtain a composite positive electrode. Pour the heating powder into the mold and flatten it. Put the wire mesh on the heating powder. The diaphragm is flattened and made into slices under a certain pressure. Compared with conventional assembly, the activation time of the positive electrode battery prepared in Example 2 can be reduced by 23%, and the activation time can reach 92ms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com