Assembled heat sink

A heat sink and assembled technology, applied in the electrical field, can solve the problems of affecting the service life of electronic components, damage to the graphite heat dissipation layer, and poor heat dissipation effect, so as to shorten the heat transfer time, improve the corrosion resistance, and speed up the heat dissipation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

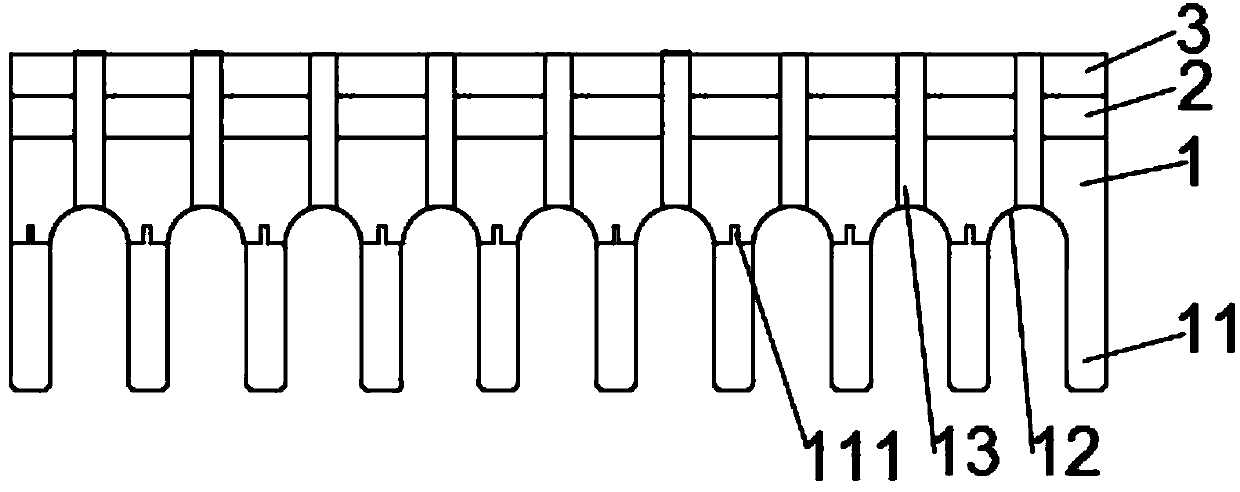

[0018] Such as figure 1 As shown, an assembled heat sink of the present invention includes a heat sink body 1, a heat sink 11 arranged on one end surface of the heat sink body 1 at equal intervals in parallel, and a heat dissipation film arranged on the other end surface of the heat sink body 1 layer 2 and the corrosion-resistant protective film layer 3 arranged on the surface of the heat dissipation film layer 2; the detachable combination of the heat dissipation fins 11 is connected to the heat dissipation fin body 1; a recess is provided between every two adjacent heat dissipation fins 11 Groove 12, the groove 12 is arranged on the end surface where the heat sink 1 is located; the heat sink body 1 is provided with a number of heat dissipation through holes 13, and the heat dissipation through holes 13 longitudinally penetrate the heat sink body 1 .

[0019] The heat sink 11 is provided with connecting convex strips 111 , and the heat sink body 1 is provided with connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com