Magnetic particle based directional adjusting system for mobile heat supplying and staged heat transferring performances and method thereof

A technology of magnetic particles and heat transfer performance, applied in heat storage equipment, indirect heat exchangers, heat exchanger types, etc., can solve the problem of neglecting one another, and achieve the effects of short heat release time, efficient recovery, and high heat storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the following will further describe the embodiments of the present invention in detail in conjunction with the accompanying drawings.

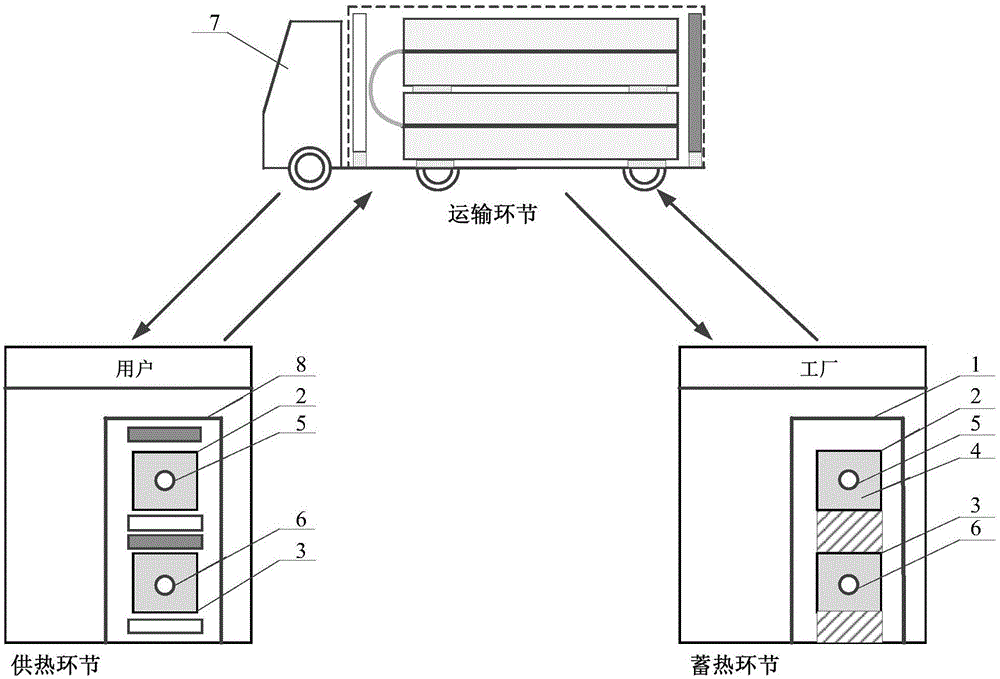

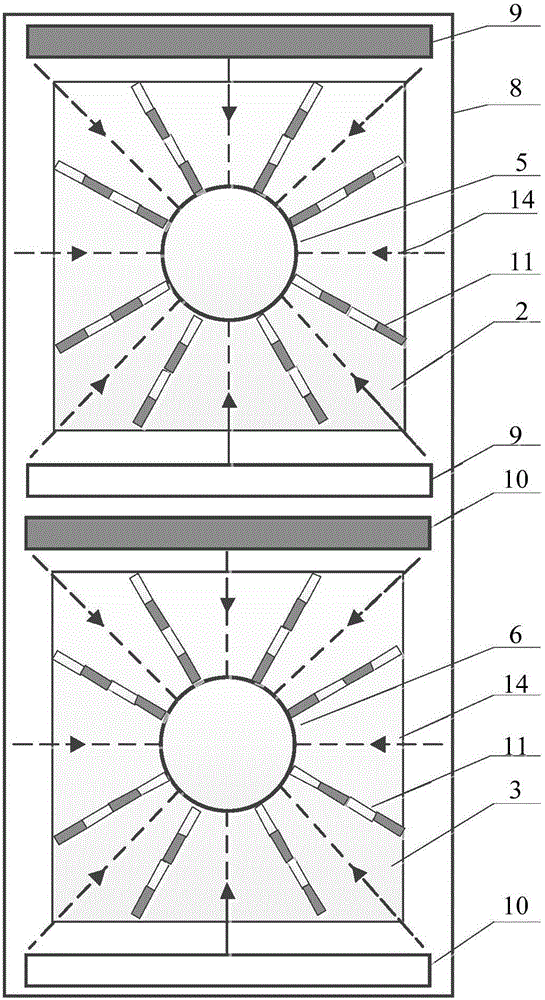

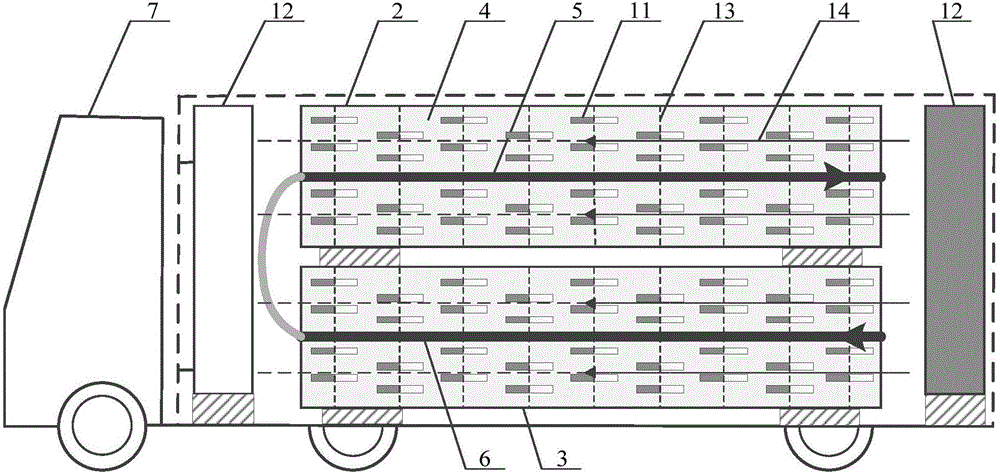

[0029] Such as figure 1 As shown, the mobile heating process includes heating links, transportation links and heat storage links. In the heat storage room 1, the phase change material 4 in the heat storage chamber I2 and the heat storage chamber II3 absorbs industrial waste heat through the heat exchange pipe I5 and the heat exchange pipe II6. After the heat storage is completed, it is transported to the user through the transportation device 7. Then the heat storage chamber I2 and heat storage chamber II3 are sent to the heat supply room 8, and the phase change material supplies heat to the user through the heat exchange pipe I5 and the heat exchange pipe II6. After the heat supply, the heat storage chamber I2 and heat storage chamber II3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com