Spiral heat exchanger

A heat exchanger, spiral type technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problem of large flow resistance, affecting thermal fluid transportation, reducing heat exchange area of heat exchanger, etc. Problems, achieve uniform discharge temperature and exhaust temperature, increase liquid flow and heat transfer capacity, and increase the effect of installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

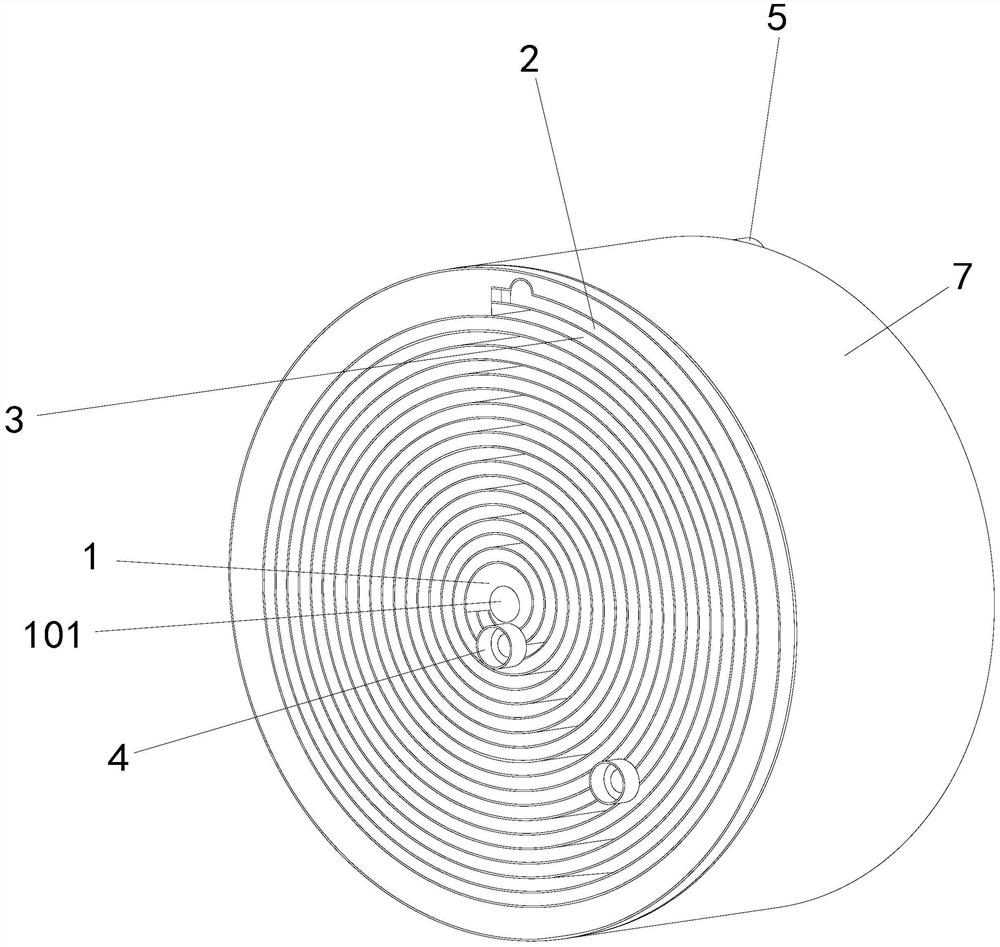

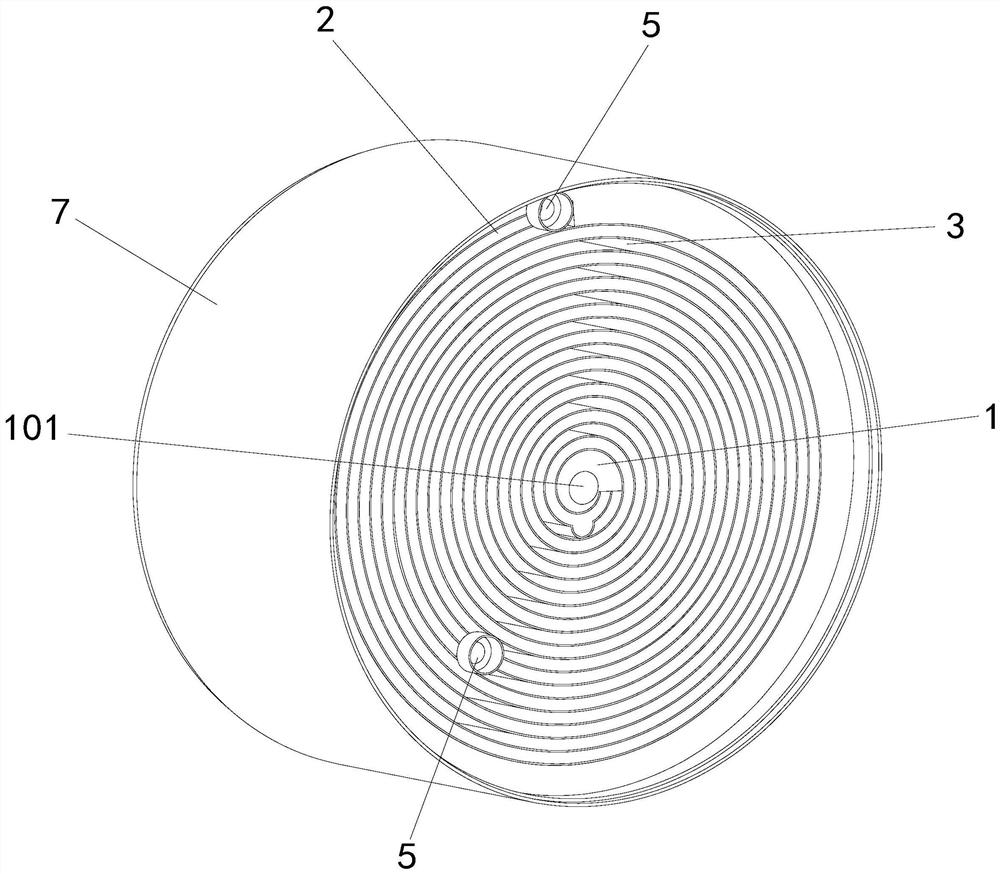

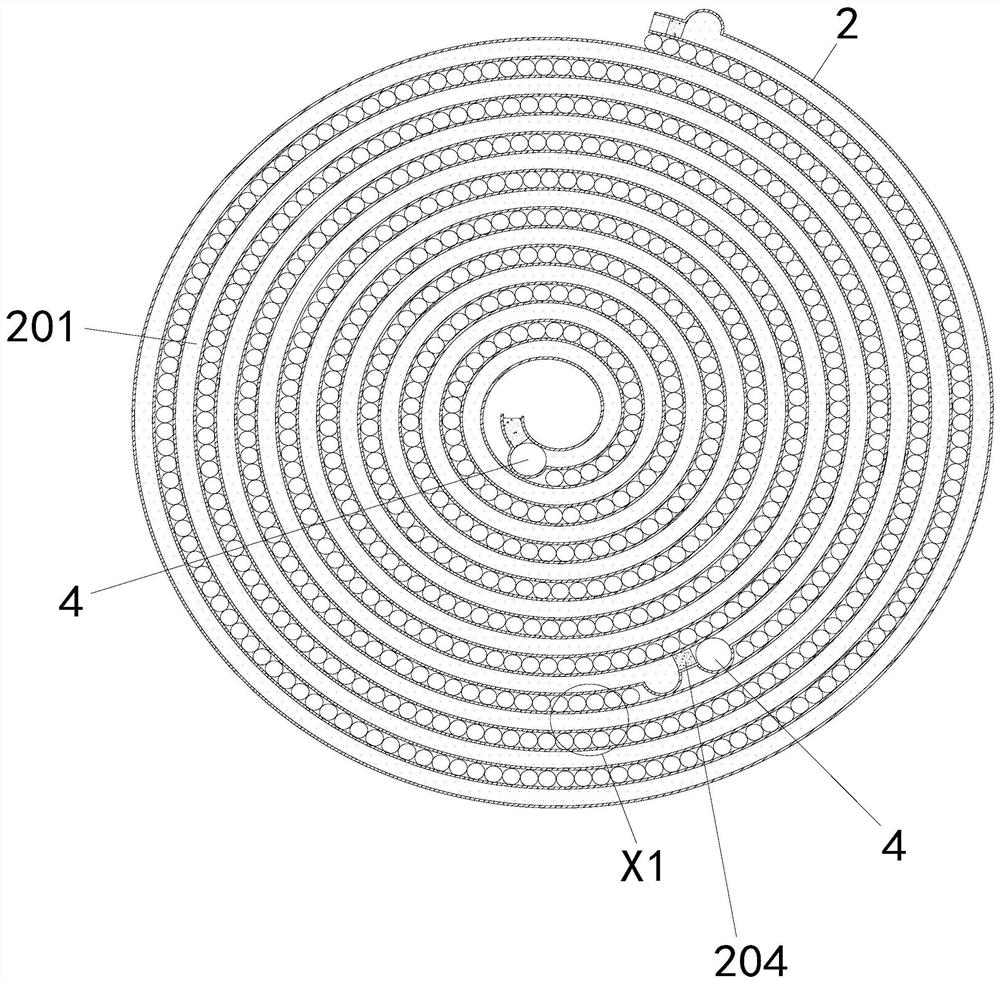

[0058] Figure 1 to Figure 6 Shown is the first specific embodiment of the spiral heat exchanger, which is mainly composed of a mandrel 1 and a liquid-feeding coil 2 . Wherein the liquid-feeding tape 2 is spirally wound on the periphery of the mandrel 1, and the winding number of the liquid-feeding tape 2 is ten turns, so that a spiral with ten helical layers is formed in the liquid-feeding tape 2 Liquid channel 201 . In order to describe the specific structure of the spiral heat exchanger more conveniently, the length direction of the mandrel 1 is now defined as the left-right direction, that is, the axis of the mandrel 1 extends left and right (extends from left to right).

[0059] In this embodiment, any two adjacent coil layers of liquid-feeding coils 2 are separated by a certain distance, thereby forming a spiral-shaped air-flowing channel 3 penetrating left and right. In order to prevent the liquid-feeding coils 2 of adjacent circles from abutting against each other, t...

Embodiment 2

[0072] Figure 8 and Figure 9 The second specific embodiment of the spiral heat exchanger is shown, which has a structure similar to that of the first embodiment, except that:

[0073]There is not only one liquid channel separating bar 204 provided in the liquid-carrying coiled strip 2, but many. The length of each liquid channel separating strip 204 extends left and right, and these liquid channel separating strips 204 are arranged at intervals along the spiral direction of the liquid carrying coil 2 . These liquid channel separation strips 204 divide the spiral liquid channel 201 into a plurality of liquid flow sub-channels 201a arranged in sequence along the helical direction of the liquid-carrying coil 2 and isolated from each other. Each liquid flow channel 201a is provided with a first liquid inlet and outlet port 4 at the inner end in the helical direction (that is, the length direction), and each liquid flow channel 201a is provided with a first liquid inlet port 4 ...

Embodiment 3

[0077] Figure 10 and Figure 11 Shown is a third specific embodiment of the spiral heat exchanger, which has a structure similar to that of Embodiment 1, the difference being:

[0078] The heat exchanger of this application is equipped with two liquid-feeding coils, one of which is spirally wound around the mandrel 1, and the number of coils is about 7. Another liquid-feeding tape 2 is spirally wound around the periphery of the first liquid-feeding tape 2, and the number of winding turns is about 3. For the convenience of description, the inner liquid-feeding coil 2 is called the first liquid-feeding coil, and the spiral liquid channel 201 formed in it is called the first spiral liquid channel; the outer liquid-feeding coil 2 is called the second The second liquid-carrying coil, the spiral liquid channel 201 formed in it is called the second spiral liquid channel. The first liquid-carrying coils of any two adjacent circles are separated by a certain distance, thereby formi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com