Polymerization reactor and method for producing water absorbent resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0058]Advantages of the present invention are demonstrated below by way of Inventive Example and Comparative Example.

Inventive Example

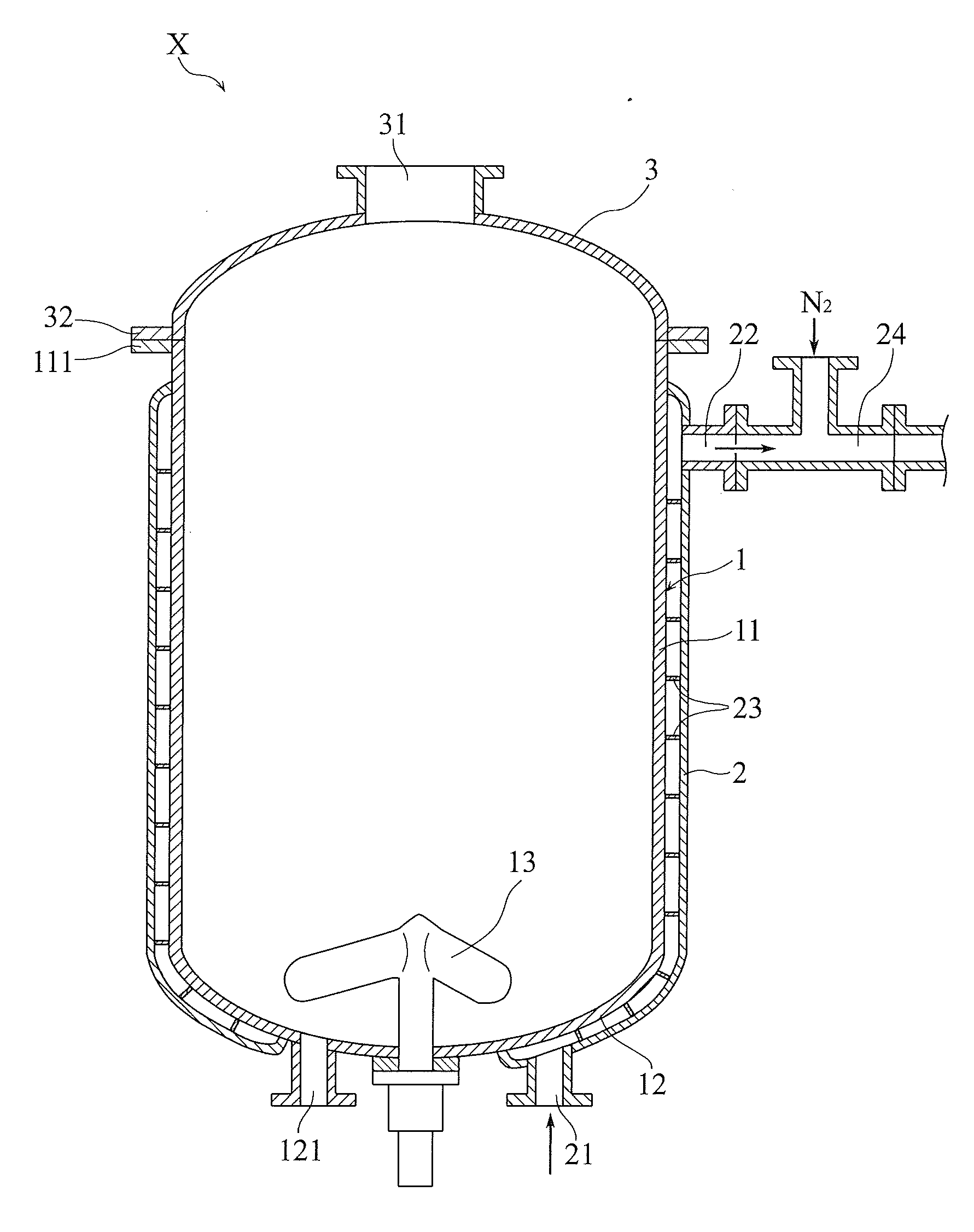

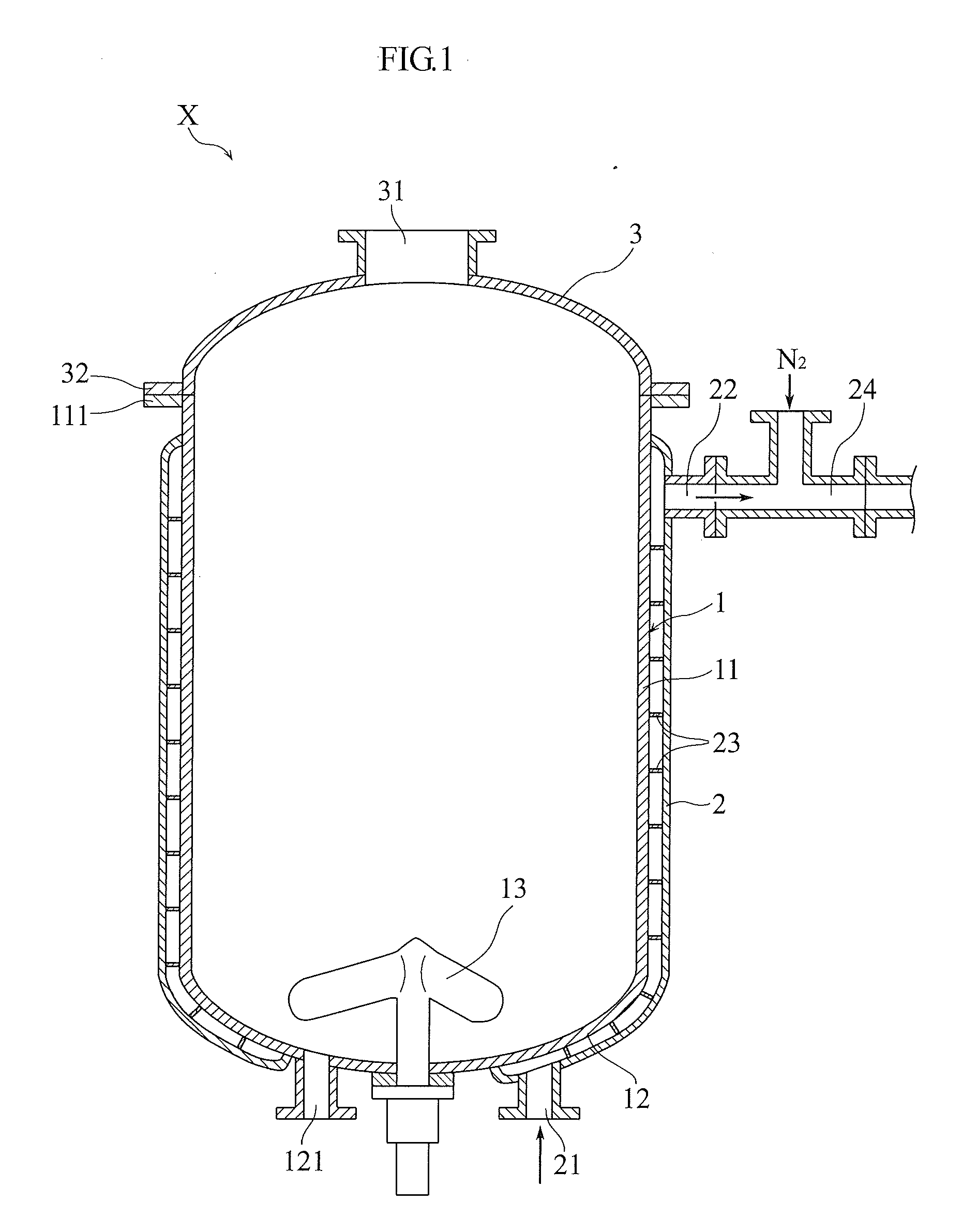

[0059]A water absorbent resin was produced by reversed phase suspension polymerization by using a polymerization reactor X having the structure schematically shown in FIGS. 1 and 2, and the time taken for each step is measured. Specifically, to produce a water absorbent resin in this example, a water-soluble ethylenically unsaturated monomer was subjected to three-stage polymerization by reversed phase suspension polymerization in a petroleum-based hydrocarbon dispersion medium (organic solvent) in the presence of a dispersion stabilizer by using a radical polymerization initiator.

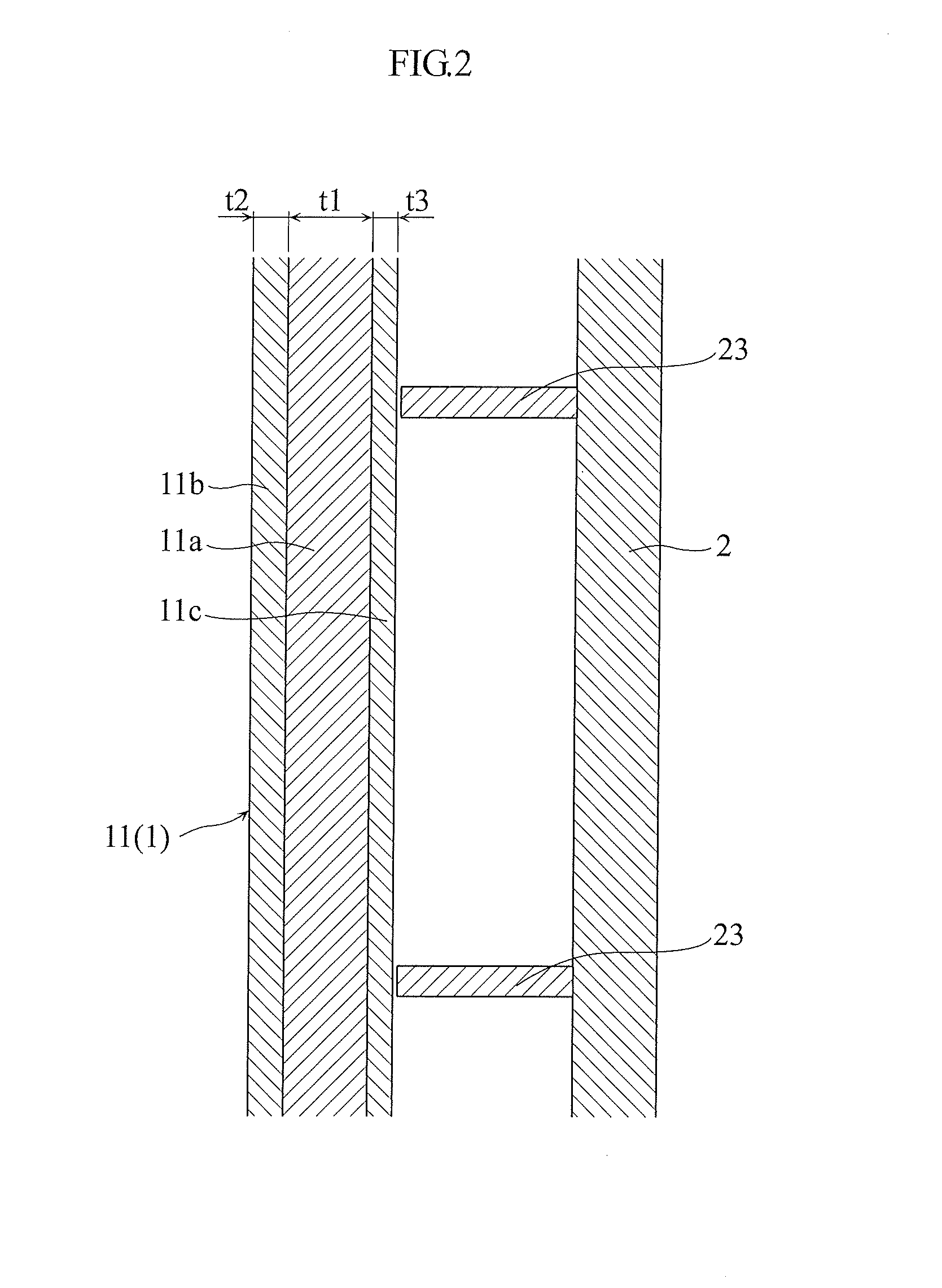

[0060]The container body 1 of the polymerization reactor X used in this Example had a volume of 60 m3. The agitating element 13 was a paddle agitator. The side wall 11 and the bottom wall 12 of the container body 1 were made of three-layer clad steel plate having a thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com