Multilayer cylindrical spiral pipe solar storage tank

A cylindrical, solar-powered technology, applied in the direction of tank cars, passenger cars, railway car body parts, etc., can solve the problems of poor uniformity and poor heat transfer effect of the storage tank system, and increase the heat transfer effect, distribution law, heat transfer time and so on. Reduce, achieve consistent and uniform effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

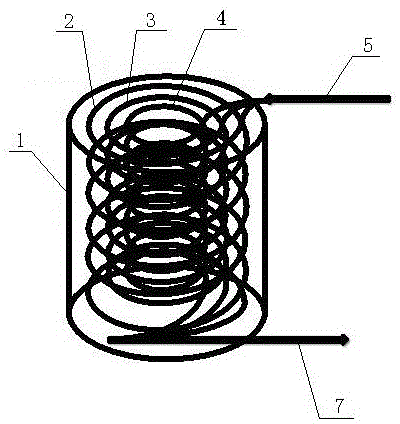

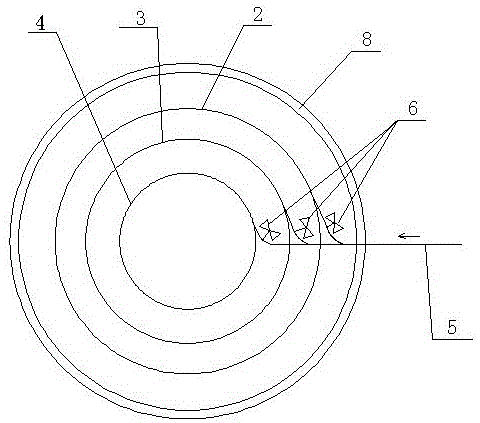

[0019] Such as figure 1 As shown, the tank body 1 of this multilayer cylindrical spiral tube solar storage tank is cylindrical, and the tank body 1 is made of austenitic stainless steel. The outer wall of the tank body 1 is provided with an insulating layer 8, and the insulating layer 8 adopts glass wool insulating material. refer to figure 2 , the tank body 1 is arranged with three layers of cylindrical spiral heat transfer pipes from the inside to the outside, that is, the outer cylindrical spiral heat transfer pipe 2, the middle cylindrical spiral heat transfer pipe 3, and the inner cylindrical spiral heat transfer pipe 4, each layer The cylindrical spiral heat transfer pipe runs through the tank body 1 from top to bottom, the middle cylindrical spiral heat transfer pipe 2 surrounds the inner cylindrical spiral heat transfer pipe 4, and the outer cylindrical spiral h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com