Preparation method of superabsorbent proton exchange membrane

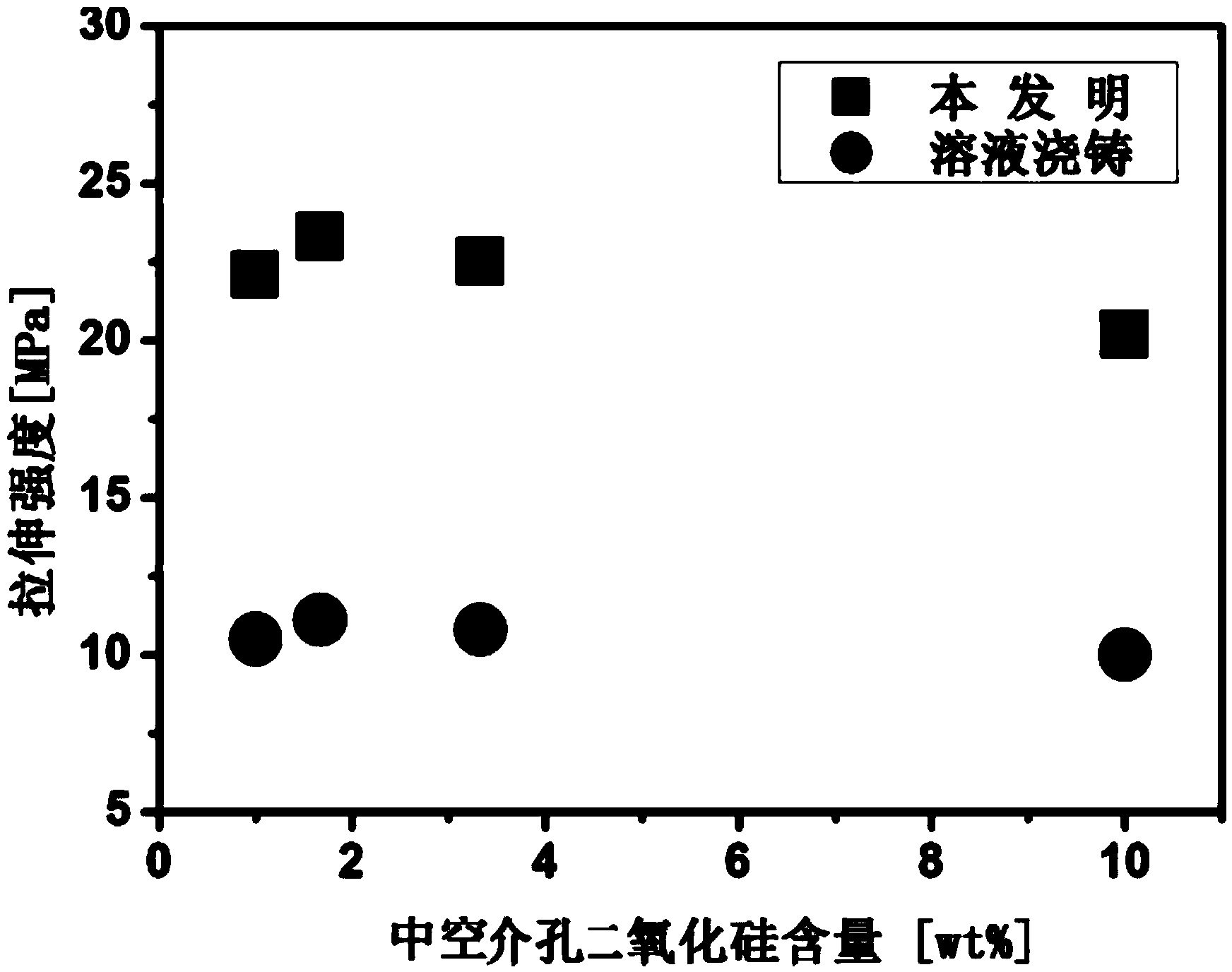

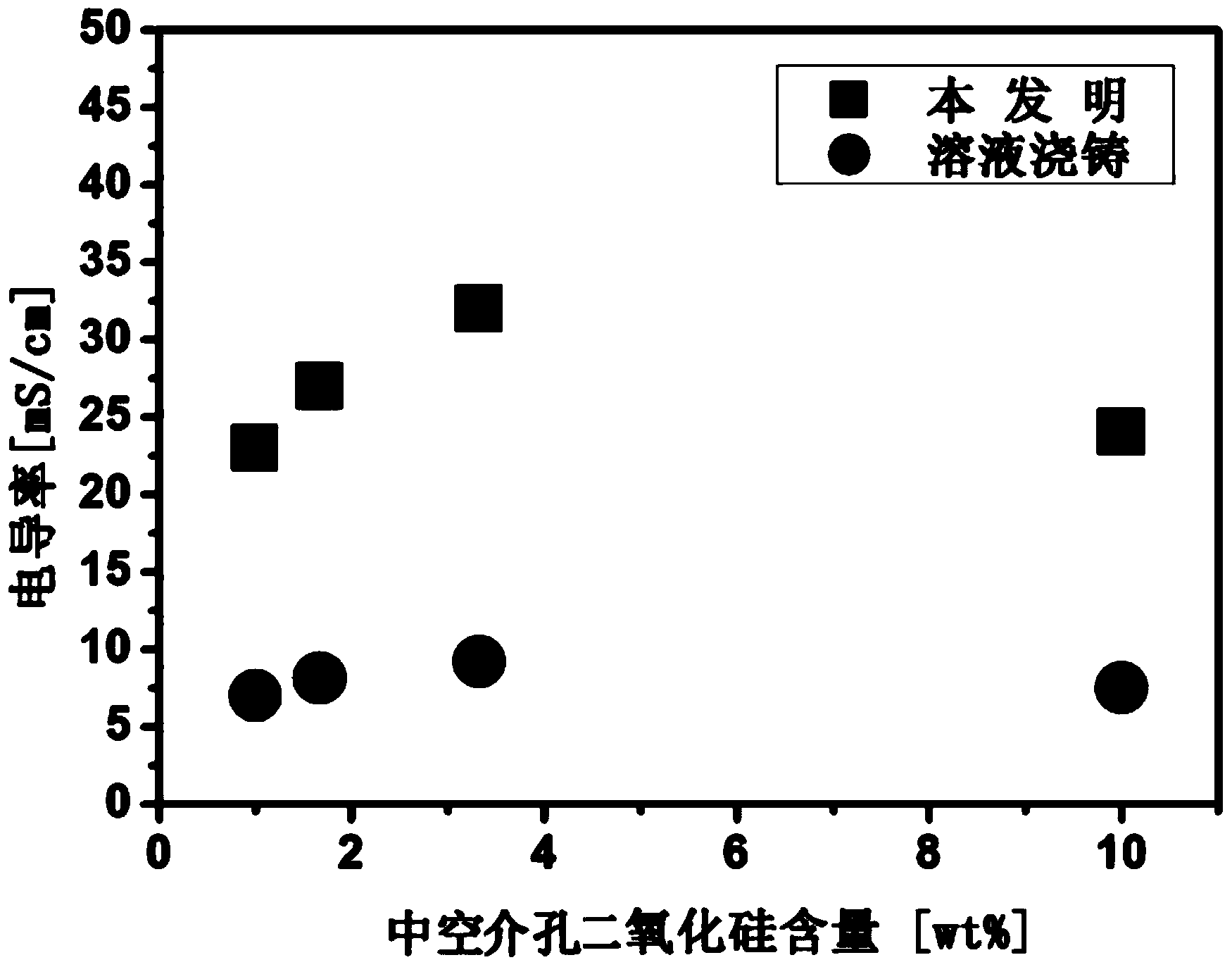

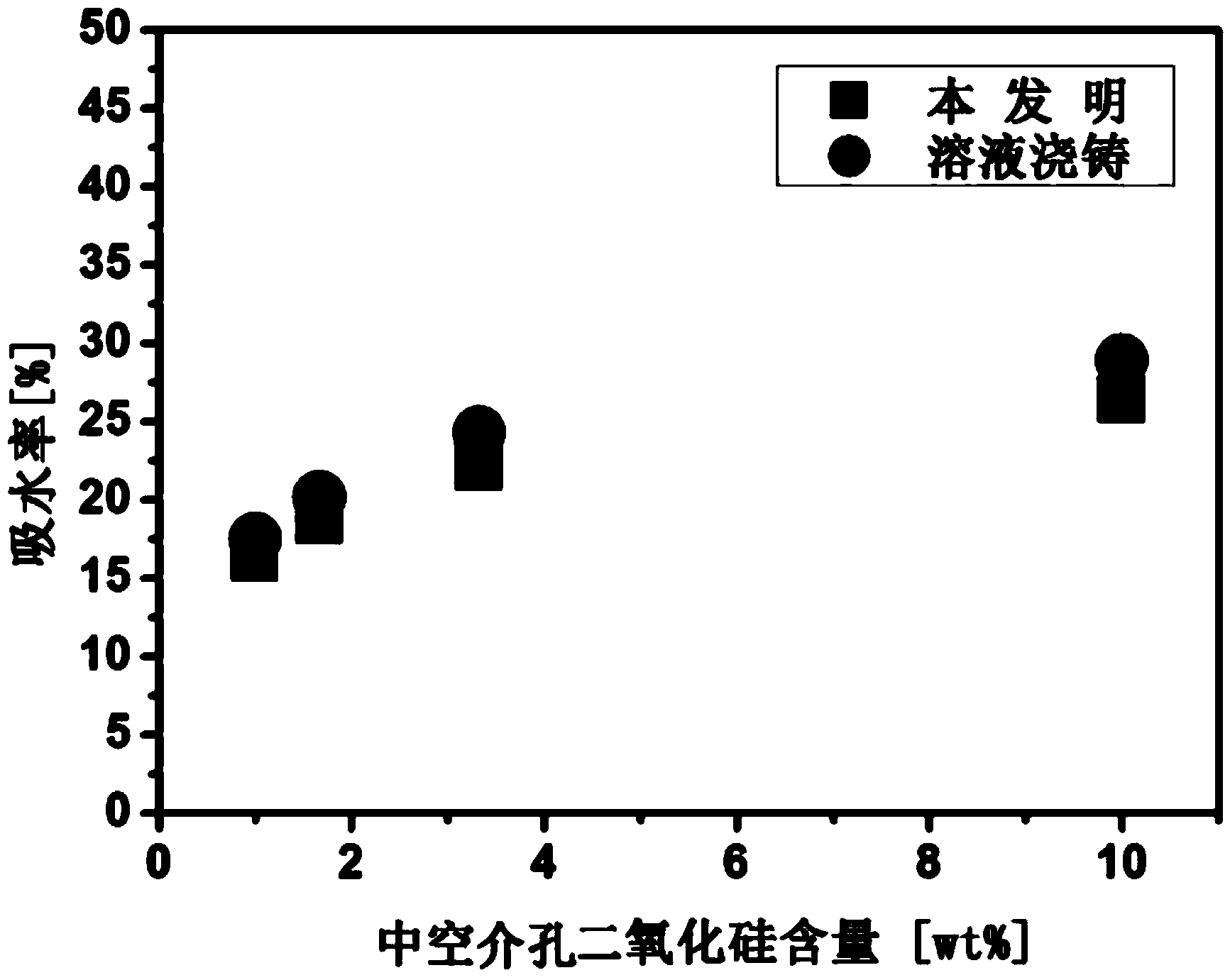

A technology of proton exchange membrane and high water absorption, which is applied in the direction of fuel cell parts, fuel cells, electrical components, etc., can solve the problems of low mechanical strength and proton conductivity, which cannot be satisfied, and achieve proton conductivity and mechanical strength Improvement, weakening effect of hindrance, high proton conductivity and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing a superabsorbent proton exchange membrane, comprising the steps of:

[0039] (1) Stir and mix 1 part of hollow mesoporous silica microspheres and 9 parts of fluorine-type perfluorosulfonic acid polymer in a mixer in a mass ratio of 1:9 to obtain a mixture;

[0040] (2) Add the mixture obtained in step (1) into the extruder hopper, melt and extrude to form a film, the temperature of the casting head is 200°C, the screw speed is 20r / min, and the linear speed of the roller press is 60cm / min;

[0041] (3) putting the film obtained in step (2) into a NaOH solution with a concentration of 0.1 wt% and soaking it for 12 hours at a temperature of 80° C. to obtain a sodium perfluorosulfonic acid film;

[0042] (4) Putting the sodium perfluorosulfonic acid film obtained in step (3) into a concentration of 0.1wt% hydrochloric acid and soaking it for 6 hours, the soaking temperature is 25°C, and then washed 3 times with deionized water to obtain high water abs...

Embodiment 2

[0046] A method for preparing a superabsorbent proton exchange membrane, comprising the steps of:

[0047] (1) Stir and mix 1 part of hollow mesoporous silica microspheres and 30 parts of fluorine-type perfluorosulfonic acid polymer in a mixer in a mass ratio of 1:30 to obtain a mixture;

[0048] (2) Add the mixture obtained in step (1) into the extruder hopper, melt and extrude to form a film, the temperature of the casting head is 190°C, the screw speed is 25r / min, and the linear speed of the roller press is 80cm / min;

[0049] (3) putting the film obtained in step (2) into a NaOH solution with a concentration of 0.5 wt% and soaking it for 8 hours at a temperature of 70° C. to obtain a sodium perfluorosulfonic acid film;

[0050] (4) putting the sodium perfluorosulfonic acid film obtained in step (3) into a concentration of 0.5wt% hydrochloric acid and soaking for 3 hours, the soaking temperature is 25°C, and then washed 3 times with deionized water to obtain high water absor...

Embodiment 3

[0054] A method for preparing a superabsorbent proton exchange membrane, comprising the steps of:

[0055] (1) Stir and mix 1 part of hollow mesoporous silica microspheres and 99 parts of fluorine-type perfluorosulfonic acid polymer in a mixer in a mass ratio of 1:99 to obtain a mixture;

[0056] (2) Add the mixture obtained in step (1) into the extruder hopper, melt and extrude to form a film, the temperature of the casting head is 180°C, the screw speed is 35r / min, and the linear speed of the roller press is 100cm / min;

[0057] (3) putting the film obtained in step (2) into a NaOH solution with a concentration of 1 wt% and soaking it for 6 hours at a temperature of 80° C. to obtain a sodium perfluorosulfonic acid film;

[0058] (4) putting the sodium type perfluorosulfonic acid film obtained in step (3) into the hydrochloric acid with a concentration of 1wt% and soaking for 1 hour, the soaking temperature is 25°C, and then washed 3 times with deionized water to obtain supera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com