Patents

Literature

50results about How to "The solution cannot be applied" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

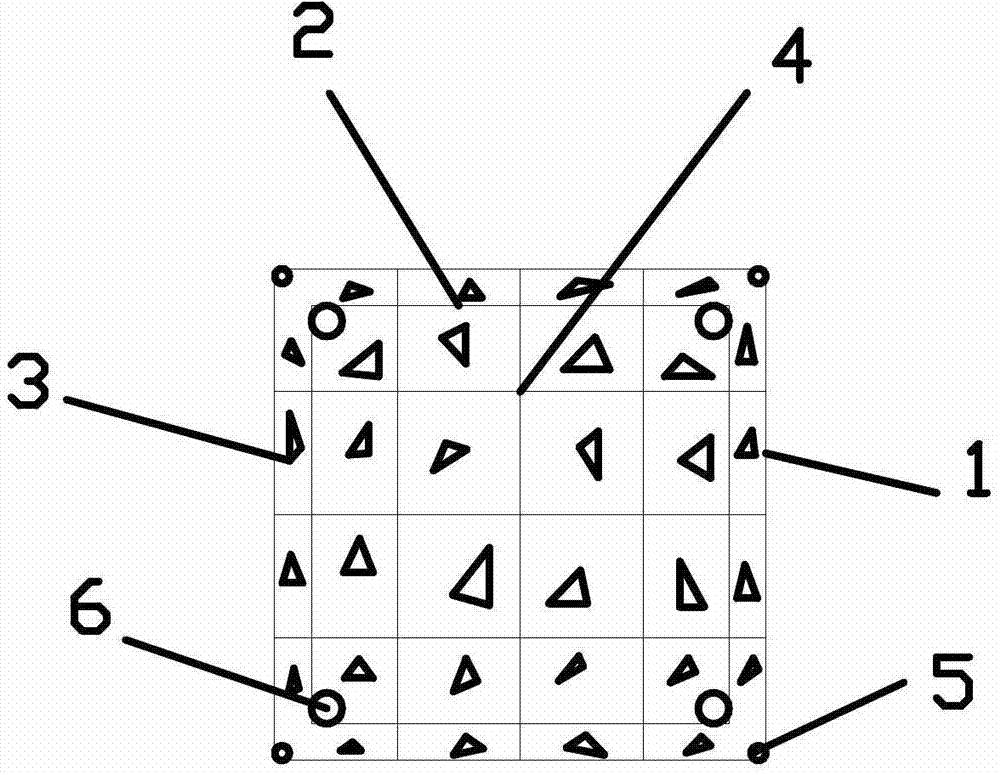

High-density flexible substrate appearance defect detection system and method based on depth learning

InactiveCN109142371AAvoid wastingSolve positioningOptically investigating flaws/contaminationHigh densitySample image

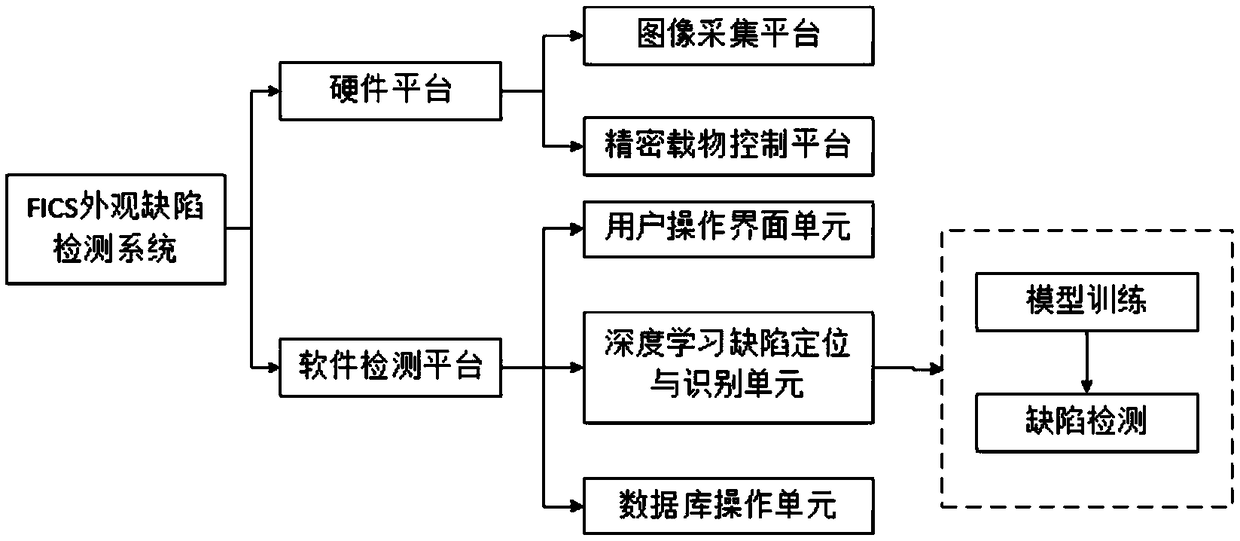

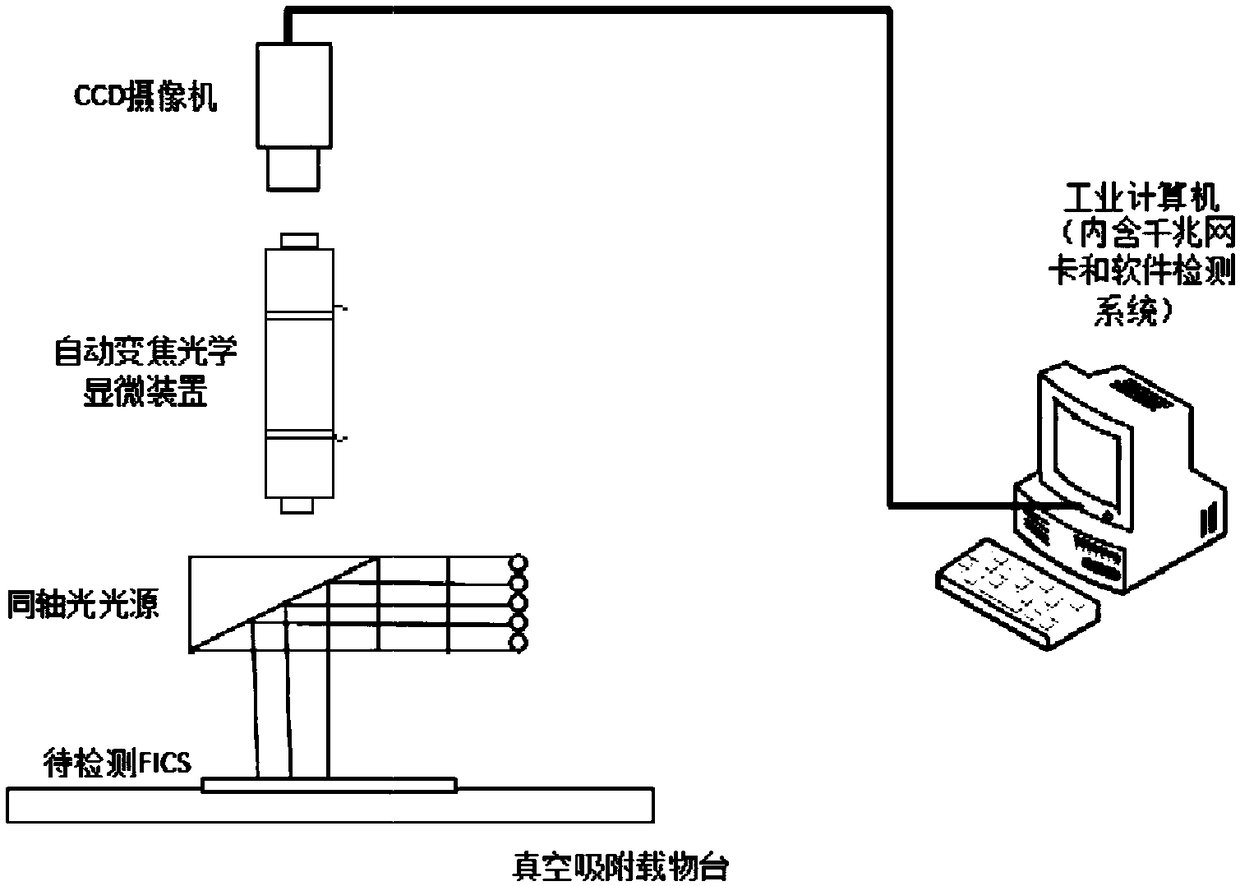

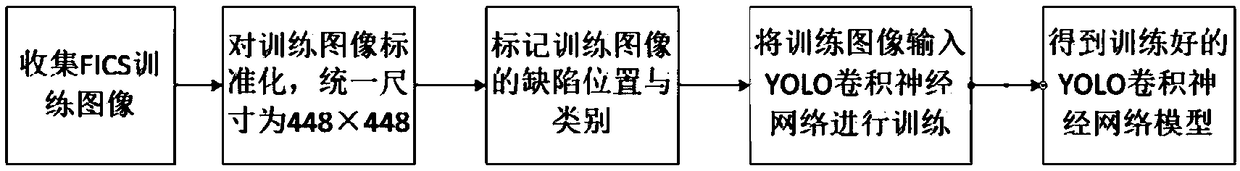

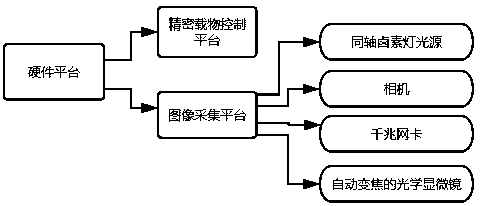

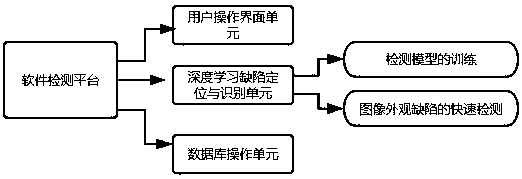

The invention discloses a high-density flexible substrate appearance defect detection system and a method based on depth learning, the method comprises a hardware platform and a software detection platform. The detecting method comprises the following steps: FICS images containing different defects is collected as training samples; pre-processing on the sample image is carried out, including the unified standard size and manual marking of the defect position and the category in the sample; a sample image is input into a depth learning model based on an improved YOLO convolution neural networkto carry out training to obtain model parameters which are output as defect positions and categories; the collected image size is standardized and input into a trained depth learning model for detection, and the defect position and the category information in the acquired image are obtained. The method can achieve the rapid positioning and the type identification of the appearance defects of the high-density flexible substrate, and solves the problem that the traditional defect detection system and the method are low in speed and is difficult to achieve high-density FICS appearance defects.

Owner:SOUTH CHINA UNIV OF TECH

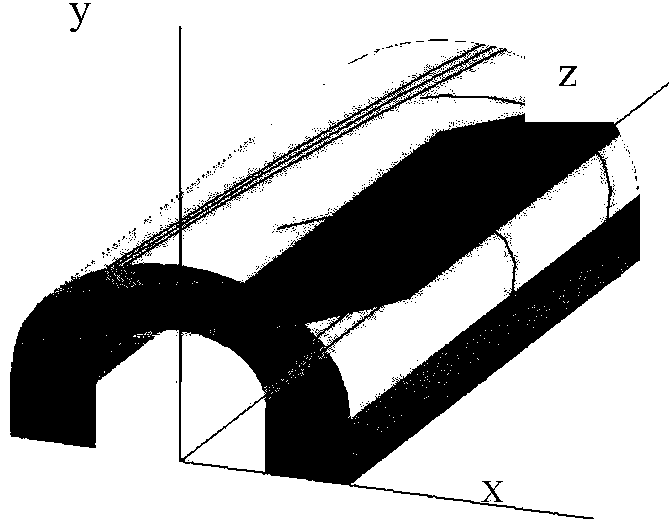

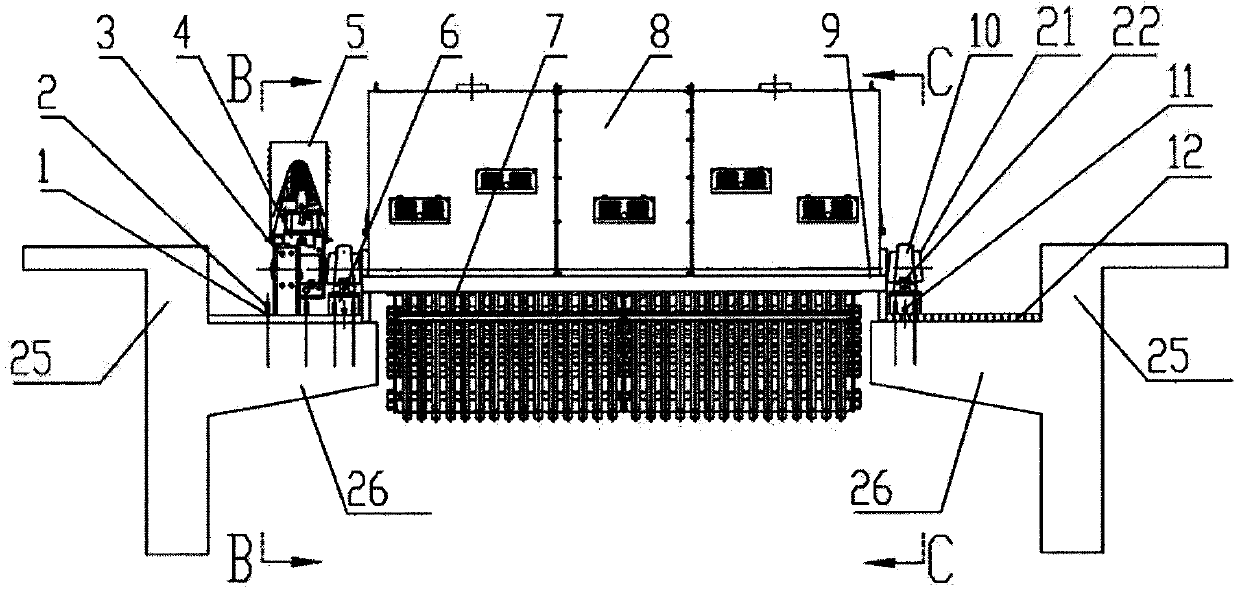

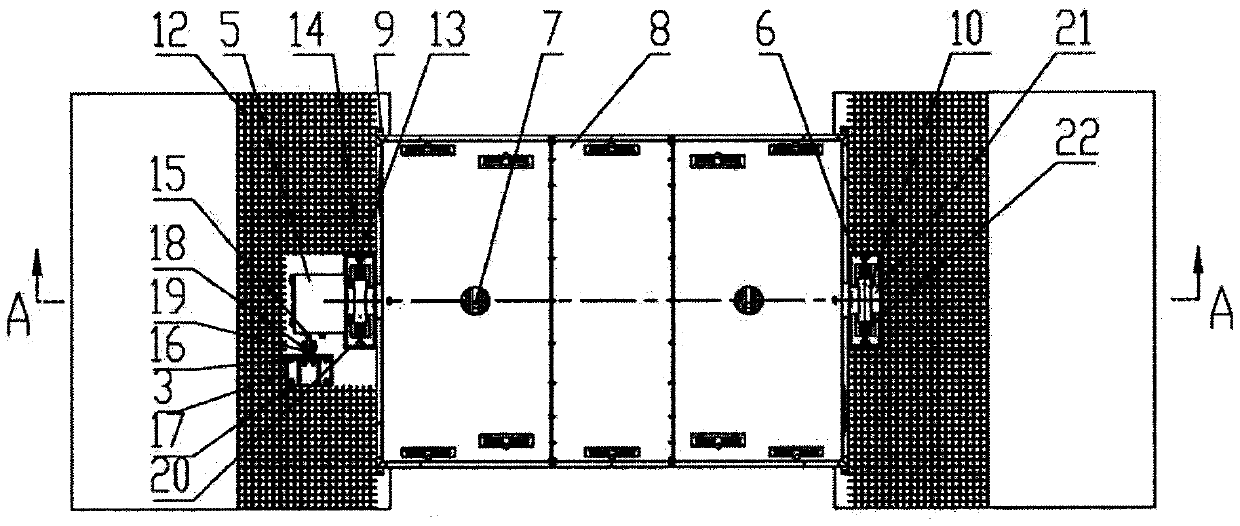

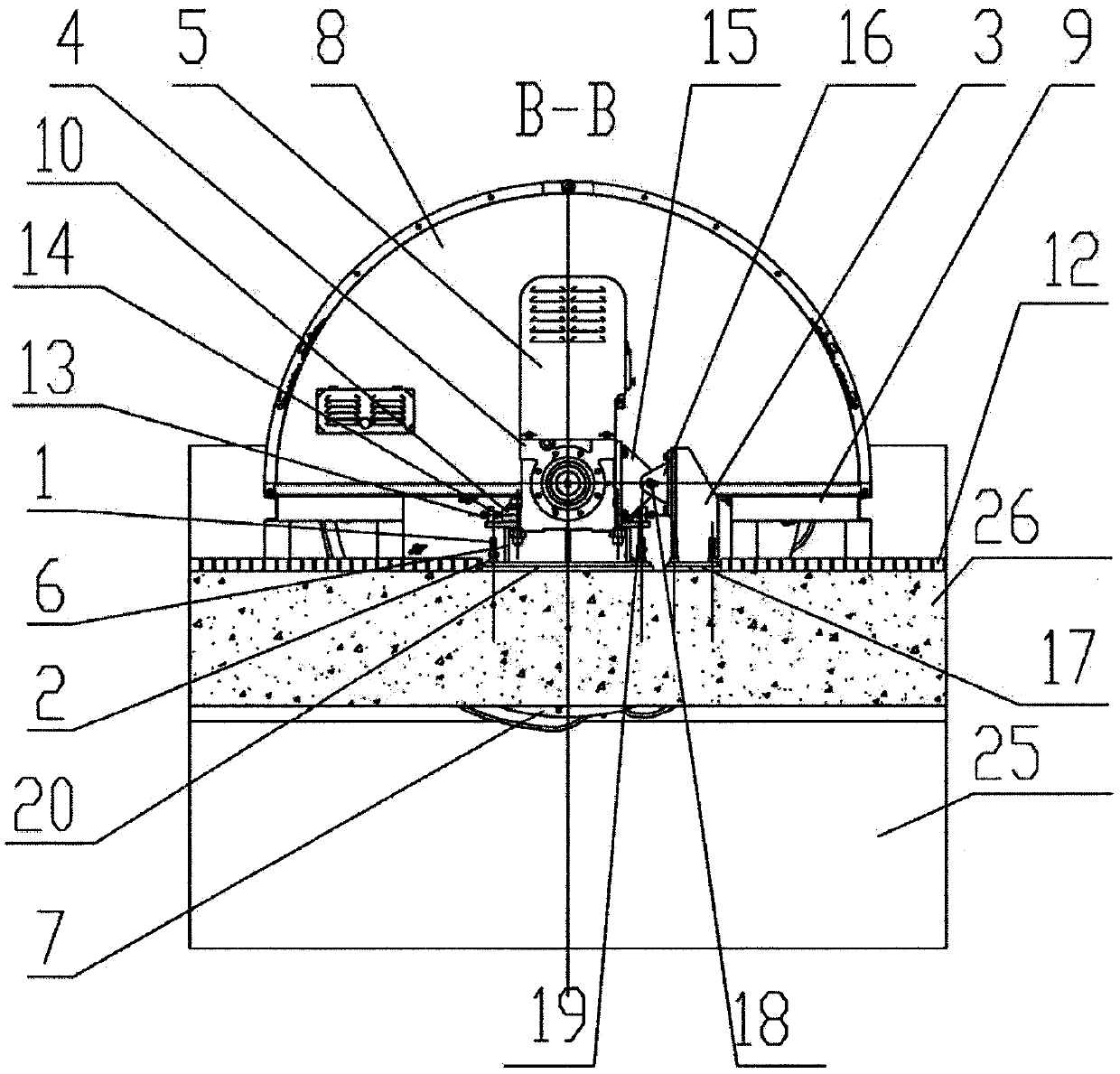

Frame-supporting column with high strength steel bars and super high strength concrete

InactiveCN103046692AReduce section sizeIncrease ultimate strainStrutsPillarsHigh strength concreteReinforced concrete

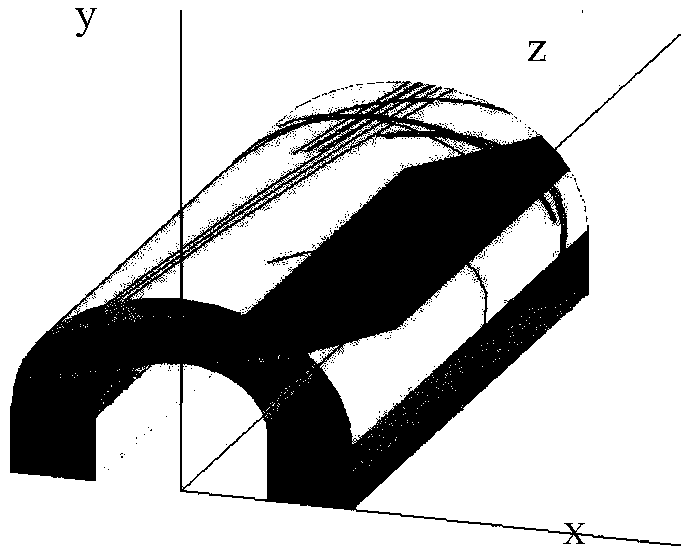

The invention relates to a reinforced concrete frame-supporting column, in particular to a frame-supporting column with high strength steel bars and super high strength concrete. The frame-supporting column overcomes defects that axial compression ratio limits of ordinary reinforced concrete frame-supporting columns and steel reinforced concrete frame-supporting columns are low, protective covers fall easily under earthquake force, longitudinal bars and steel flanges are easy to bend, the columns are difficult to repair after an earthquake, and high strength steel bars and super high strength concrete cannot be applied, and defects that node constructions of steel reinforced concrete and steel pipe concrete frame-supporting columns are complex, the steel pipe concrete frame-supporting columns do not constrain concrete fully, and steel pipes are easy to bend. The frame-supporting column comprises longitudinal high strength steel bars, high strength closed stirrups and self-compaction super high strength concrete; and constraints include that stirrup spacing of concrete protective covers in whole concrete ranges from 30mm to 35mm, outer surfaces are aligned to outer surfaces of concrete frame-supporting columns, and the stirrup spacing of longitudinal high strength steel bars is constrained to range from 60 mm to 120 mm. By aid of constraining of closely-matched high strength welding closed stirrups on the whole concrete, mechanical properties of super high strength concrete are improved, anti-seismic properties of the column are improved, and the frame-supporting column has a wide application prospect in high-rise or super high-rise structures.

Owner:贵州中建伟业建设(集团)有限责任公司

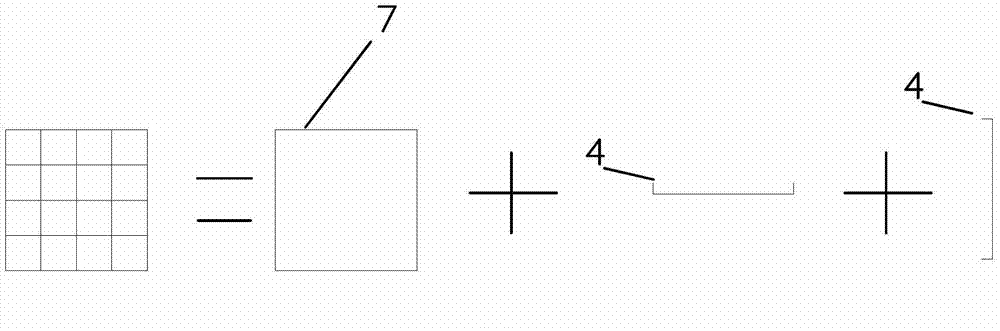

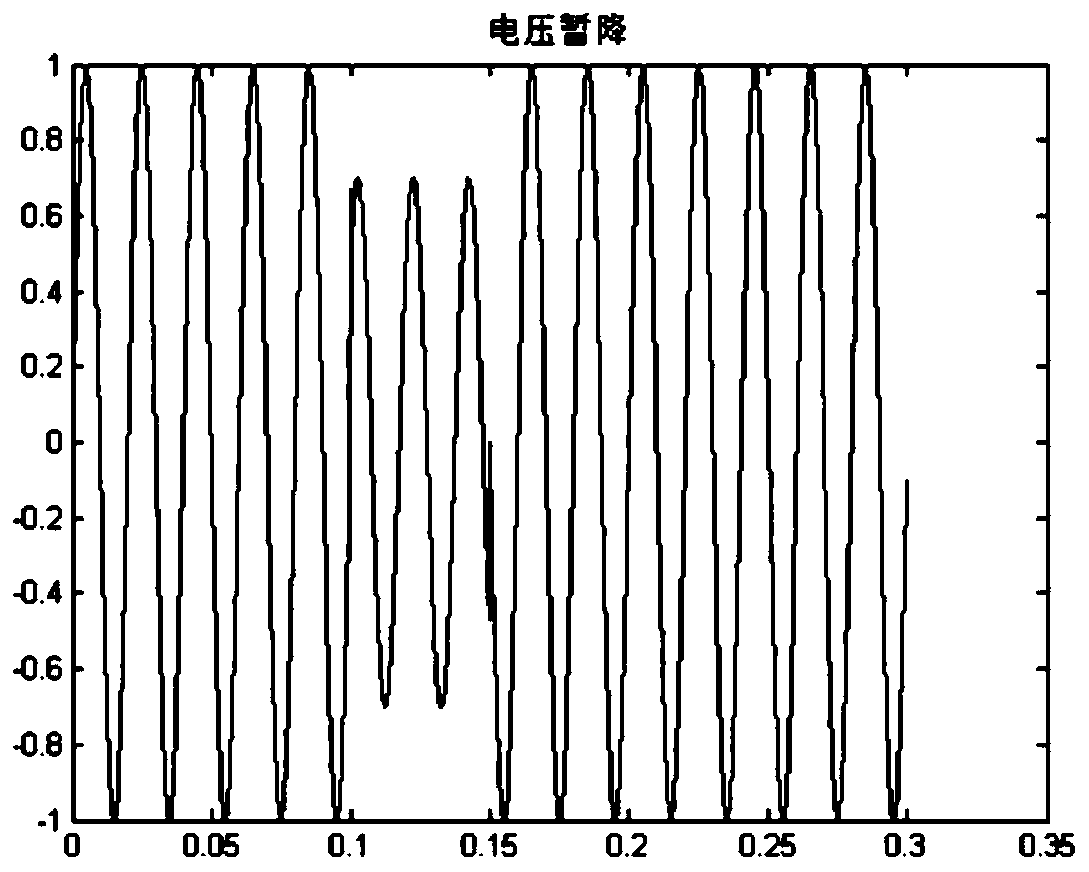

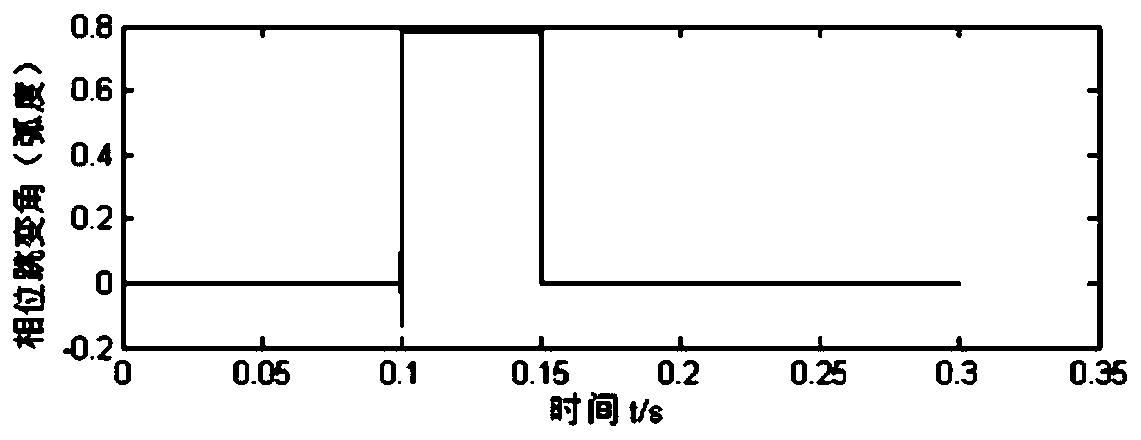

Single-phase voltage sag detection method and system based on EEMD method and two-point method and application

InactiveCN110320401AThe solution cannot be appliedSimple calculationCurrent/voltage measurementFault locationData segmentDecomposition

The invention provides a single-phase voltage sag detection method and system based on an EEMD (ensemble empirical mode decomposition) method and a two-point method and application. According to the method, a sampling value is utilized to construct a data segment suitable for online calculation, the EEMD method is utilized to extract network voltage fundamental waves, harmonic interference is filtered out, the sage depth and phase jump angle of a current network voltage are calculated through the two-point method, and finally voltage sag online rapid detection is realized. Therefore, an original signal can be decomposed into IMF with different frequencies, and most harmonic components can be filtered out; and in combination with the EEMD method, the problem that the two-point method is notapplicable under the situation that harmonic distortion is contained is solved, and the advantages of rapidity and accuracy of the two-point method are reserved.

Owner:UNIV OF JINAN +1

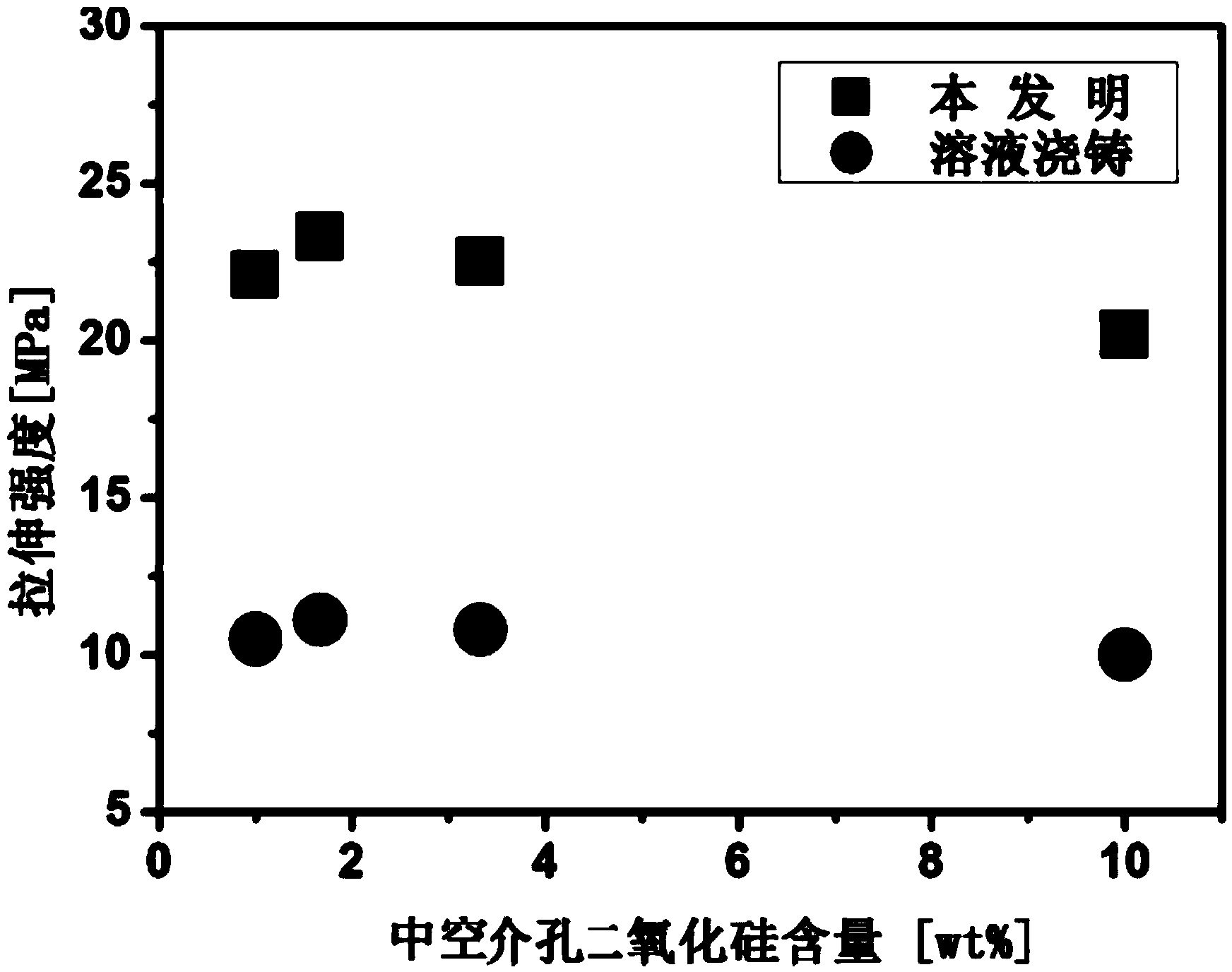

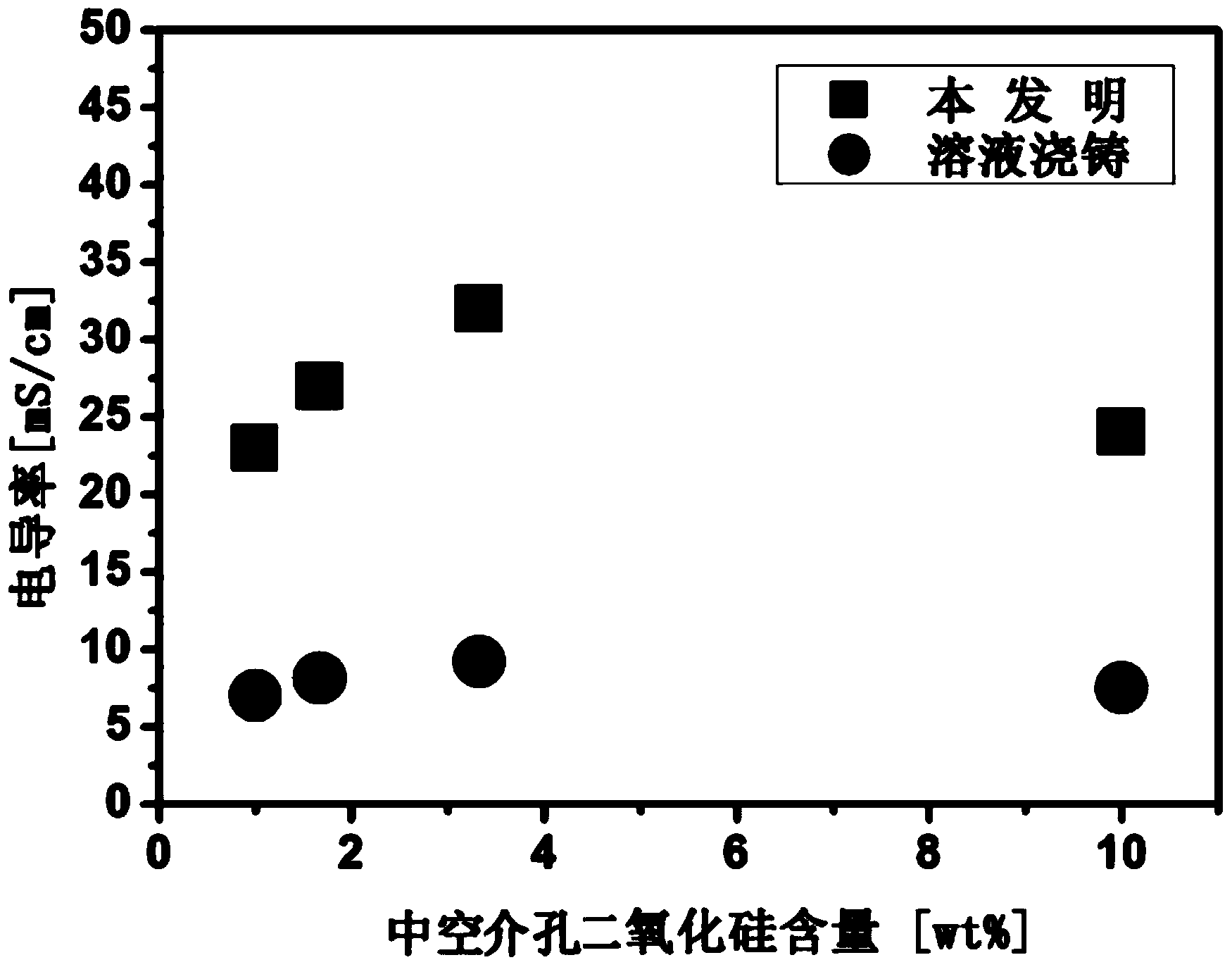

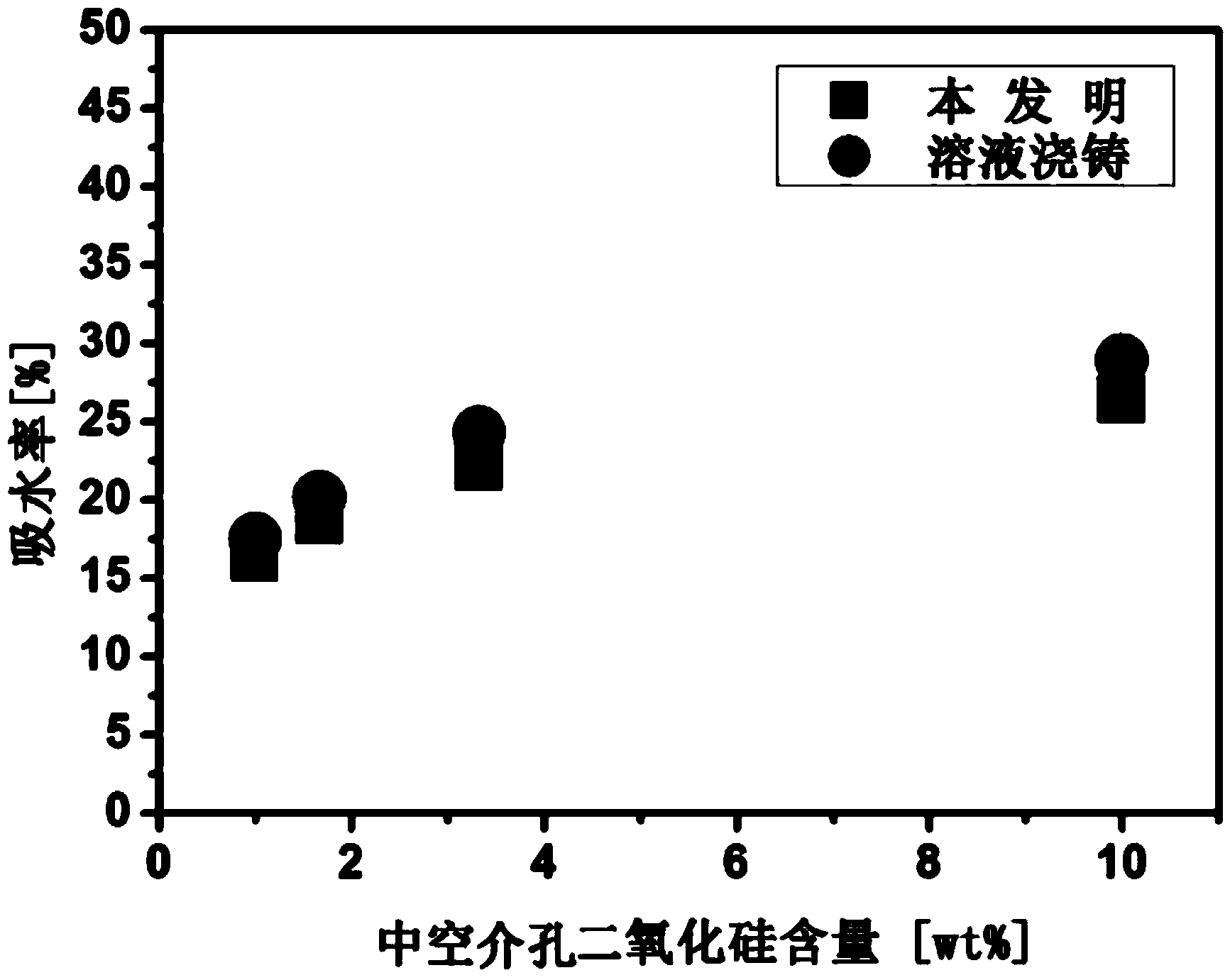

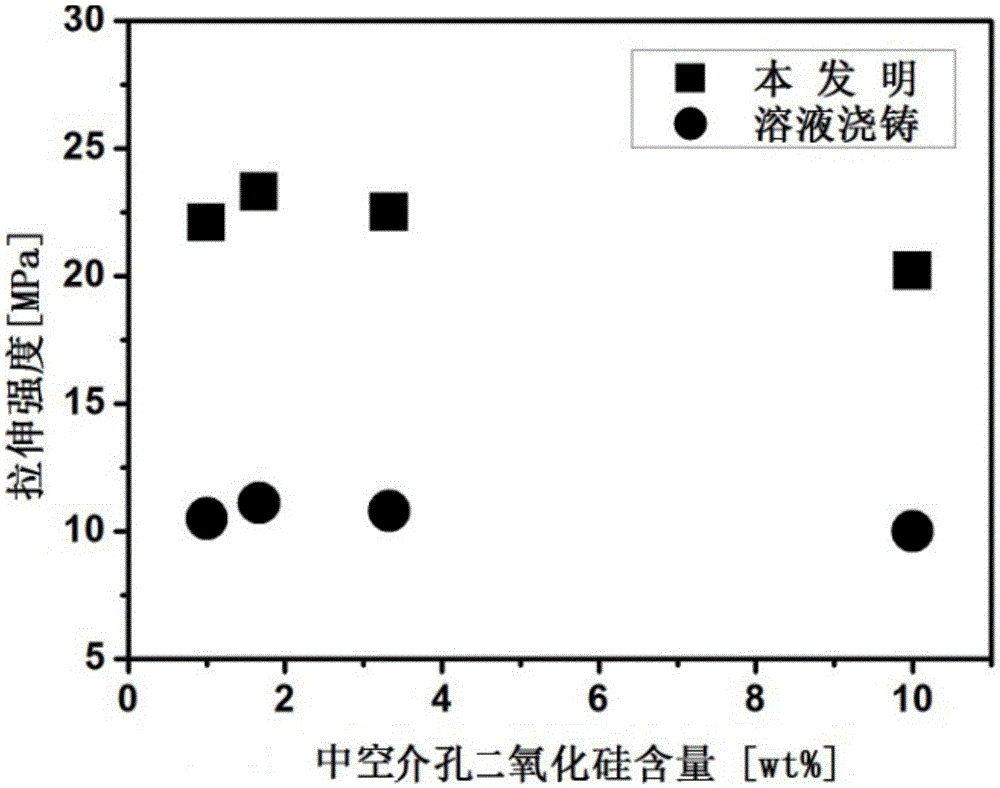

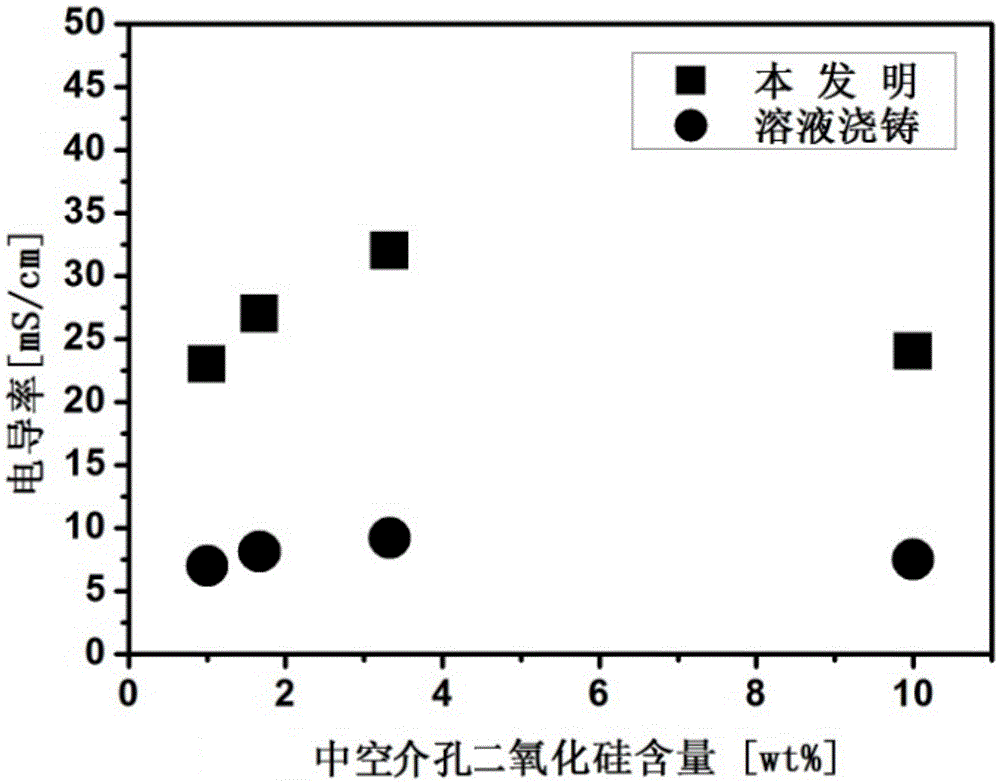

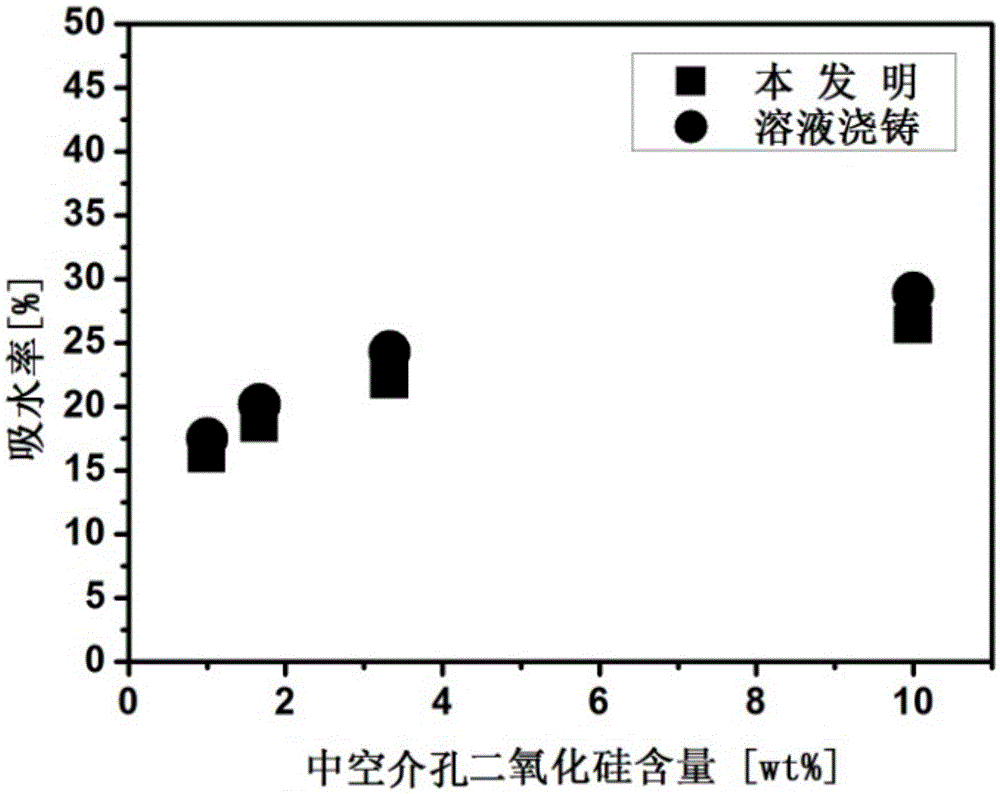

Preparation method of superabsorbent proton exchange membrane

ActiveCN104078691AImprove conductivityHigh mechanical strengthCell component detailsFuel cell detailsMicrosphereMesoporous silica

The invention discloses a preparation method of a superabsorbent proton exchange membrane. The preparation method of the superabsorbent proton exchange membrane comprises the following steps: (1) stirring for mixing hollow mesoporous silica microspheres with fluorous perfluorinated sulfonic acid polymers according to a mass ratio of 1 to (9-99) to obtain a mixture; (2) adding the mixture obtained in the step (1) into an extruder for melting and extruding so as to form a membrane under the conditions that the temperature of the head of a membrane casting machine is 180-200 DEG C, the rotation speed of a screw rod is 20-35r / min and the linear speed of a roller press is 60-100cm / min; (3) putting the membrane obtained in the step (2) into 0.1-1wt% sodium hydroxide solution for soaking at the temperature of 60-80 DEG C for 4-12 hours so as to obtain a sodium perfluorinated sulfonic acid membrane; (4) putting the sodium perfluorinated sulfonic acid membrane obtained in the step (3) into 0.1-1wt% hydrochloric acid for soaking at the temperature of 20-30 DEG C for 1-6 hours, then washing the membrane with deionized water so as to obtain the superabsorbent proton exchange membrane. Compared with a membrane prepared by adopting a casting method using the solution, the superabsorbent proton exchange membrane prepared by adopting the method has higher conductivity and mechanical strength.

Owner:JUHUA GROUP TECH CENT

Application of deep learning in product appearance defect detection

InactiveCN111340798ALow costEasy constructionImage analysisOptically investigating flaws/contaminationData setVisual inspection

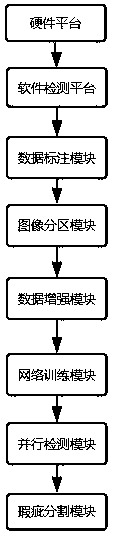

The invention discloses application of deep learning in product appearance defect detection, and relates to the technical field of defect detection. The objective of the invention is to solve problemsof accuracy and real-time performance of a detection system, a hardware platform, a software detection platform, a data labeling module, an image partitioning module, a data enhancement module, a network training module, a parallel detection module and a defect segmentation module are included; the hardware platform comprises a precise object carrying control platform and an image acquisition platform. According to the invention, segmentation is realized based on the detection technology; the types and positions of the flaws can be obtained; the specific shape can be obtained; a data enhancement operation is used to greatly reduce the cost required by data set making, deep learning parallel detection is adopted, the detection precision is guaranteed, the detection speed is improved, manual visual inspection is replaced, the working efficiency is improved, the waste of human resources caused by manual visual inspection is avoided, and the invention can automatically and quickly detectdefects, and marks the positions and types of the defects.

Owner:浙江一木智能科技有限公司

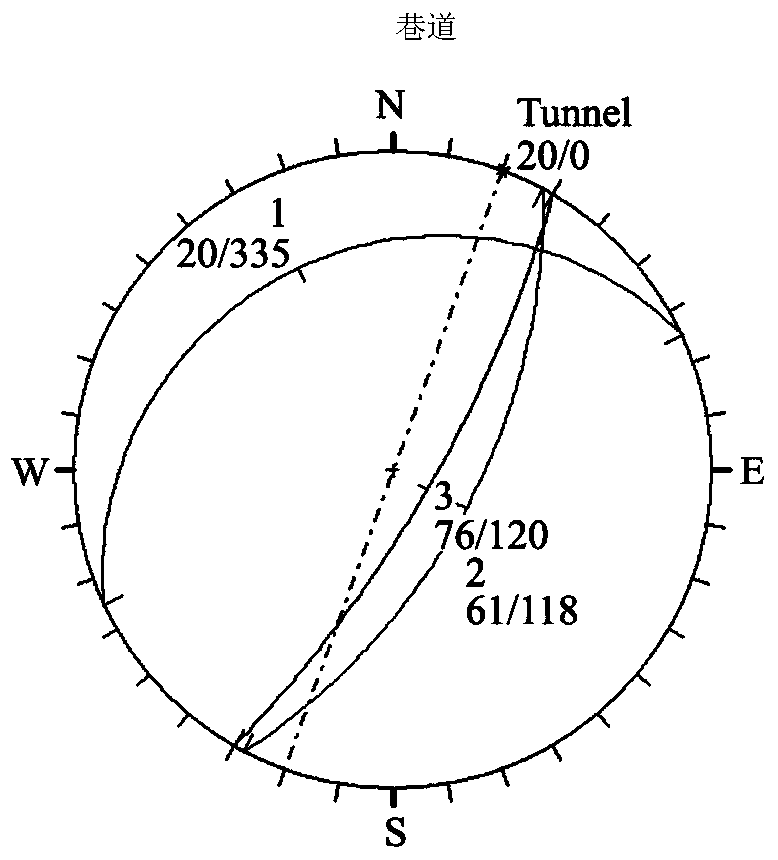

Method for determining jointed rock mass roadway axis strike

InactiveCN103713332AThe solution cannot be appliedPrecise positioningGeological measurementsModel selectionGeological survey

Provided is a method for determining a jointed rock mass roadway axis strike. The method includes the first step of utilizing a General Block program to establish a roadway model and selecting three sets of representative structure planes according to roadway cross section shapes and geometrical parameters obtained through engineering geological surveys, the second step of utilizing an Unwedge program to establish a roadway model and carrying out block computation, and the third step of outputting an information map of the number of blocks directly dropping and the minimum safety factor of the blocks when the roadway is located within 0-180 degrees in the axial direction, and determining the optimum jointed rock mass roadway axis strike with the minimum number of the blocks directly dropping and the minimum safety factor as evaluation indexes. According to the method for determining the jointed rock mass roadway axis strike, the defect that in the prior art, selection of jointed rock mass representative structure planes is unscientific is overcome, the evaluation indexes for determining the optimum jointed rock mass roadway axis strike are improved, and selection of the optimum jointed rock mass roadway axis strike can be accurate and reasonable.

Owner:广西华锡集团股份有限公司

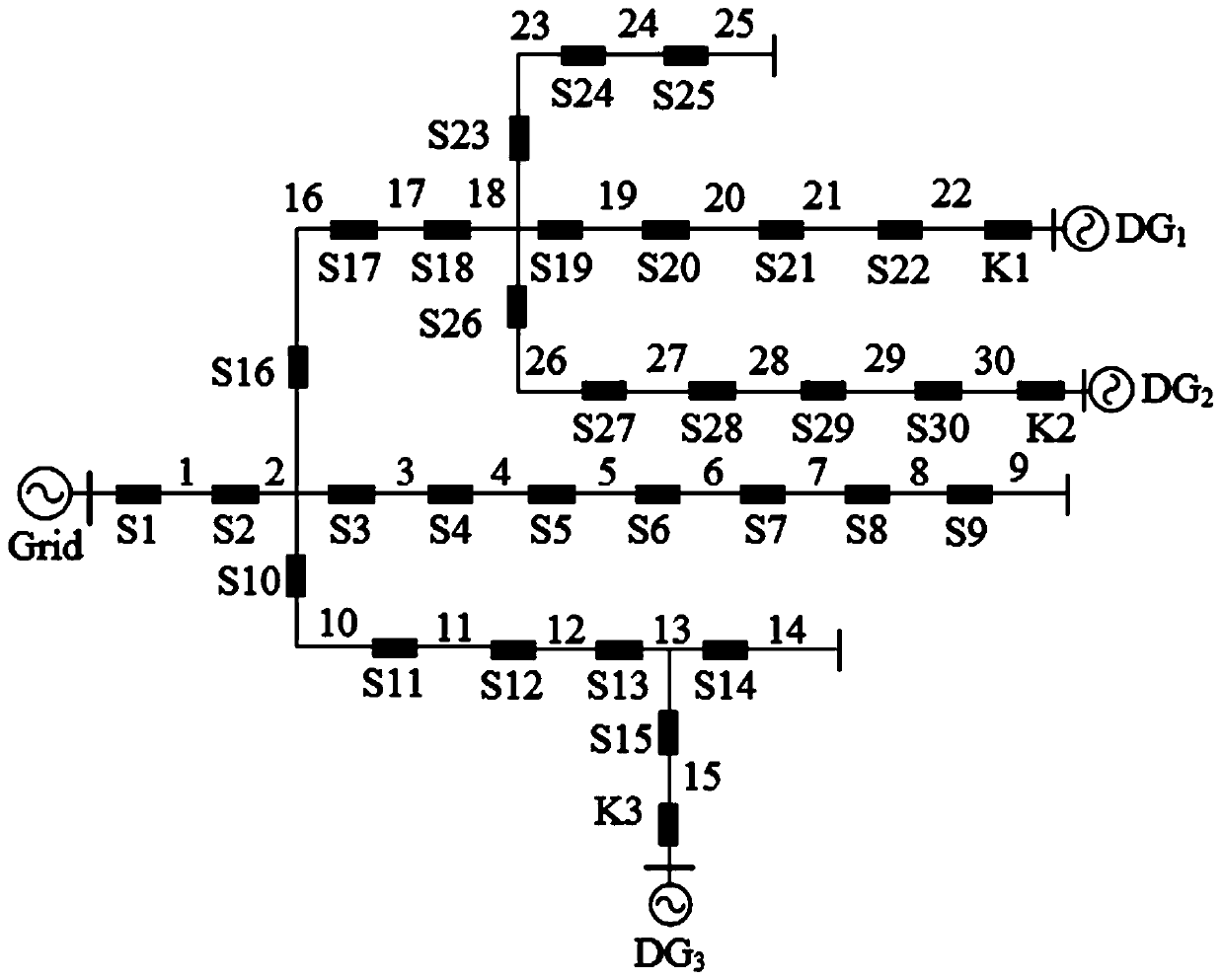

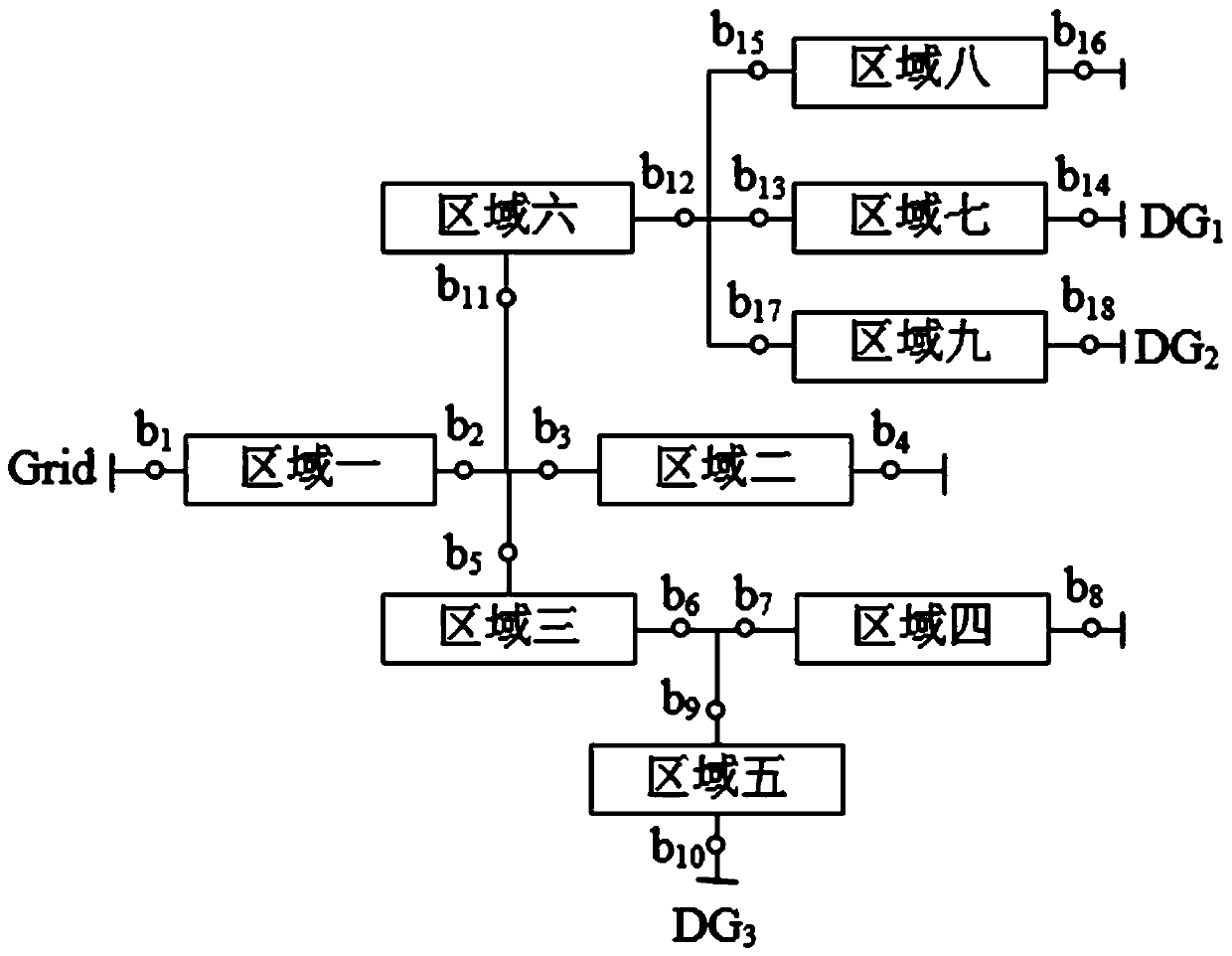

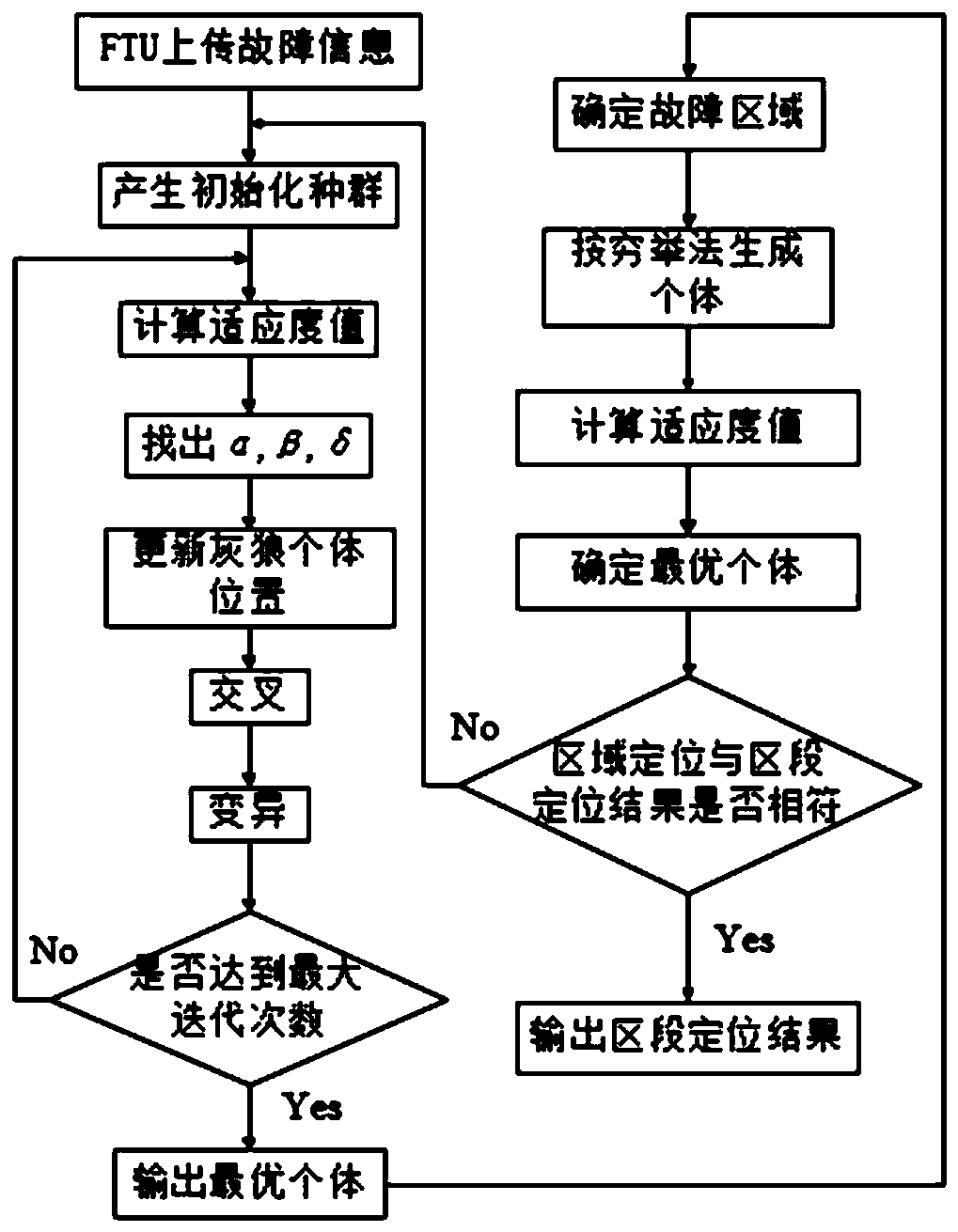

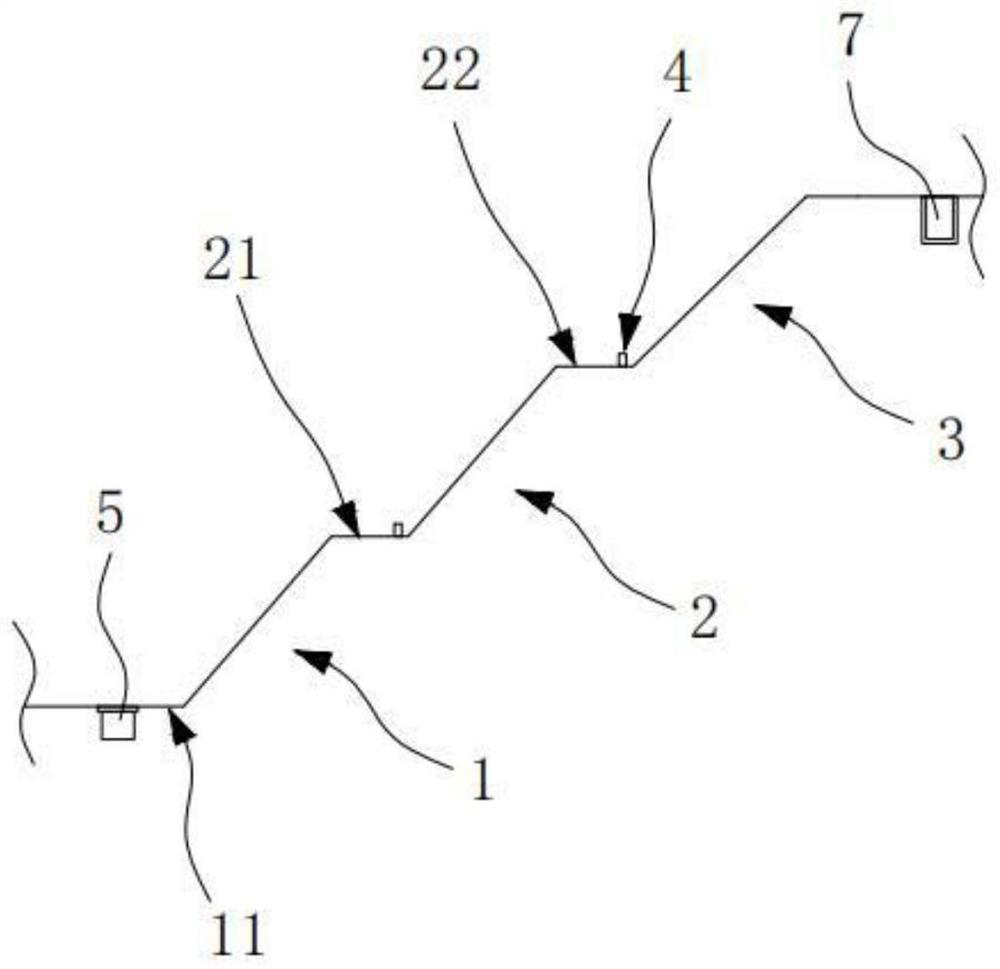

Power distribution network fault positioning method based on hierarchical model and improved grey wolf optimization algorithm

ActiveCN110554280ASimplify complex distribution networksReduce dimensionalityFault location by conductor typesArtificial lifeEvaluation functionDistribution networks

The invention relates to a power distribution network fault positioning method based on a hierarchical model and an improved grey wolf optimization algorithm, wherein the method comprises the steps: firstly constructing a switching function which can adapt to the access of a plurality of distributed power supplies on the premise of determining a coding rule; establishing a hierarchical model of the power distribution network according to the characteristics of a switching function value after a fault occurs, and establishing a corresponding evaluation function according to the hierarchical model; and for solving the problem that the grey wolf optimization algorithm is slow in convergence speed, in combination with the fault positioning model, introducing crossover and mutation operations into a basic binary grey wolf optimization algorithm position updating formula, so that the convergence speed and the optimization precision of the algorithm are improved; finally, applying the established hierarchical model and the improved grey wolf optimization algorithm to the fault section positioning of the power distribution network containing the distributed power supply. The hierarchical model and the improved grey wolf algorithm adopted by the invention can quickly and accurately realize fault section positioning of the power distribution network, have certain fault tolerance, and aresuitable for fault positioning of the complex power distribution network containing the distributed power supply.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

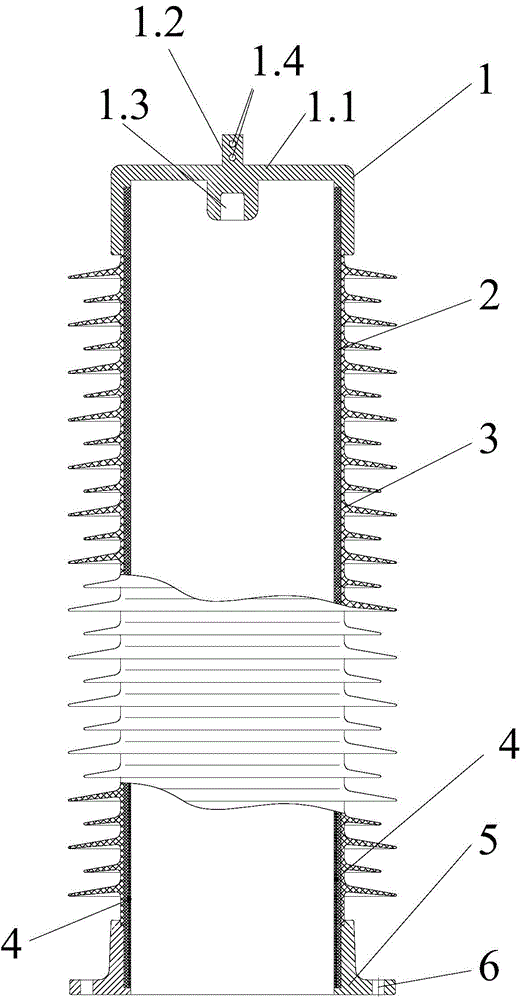

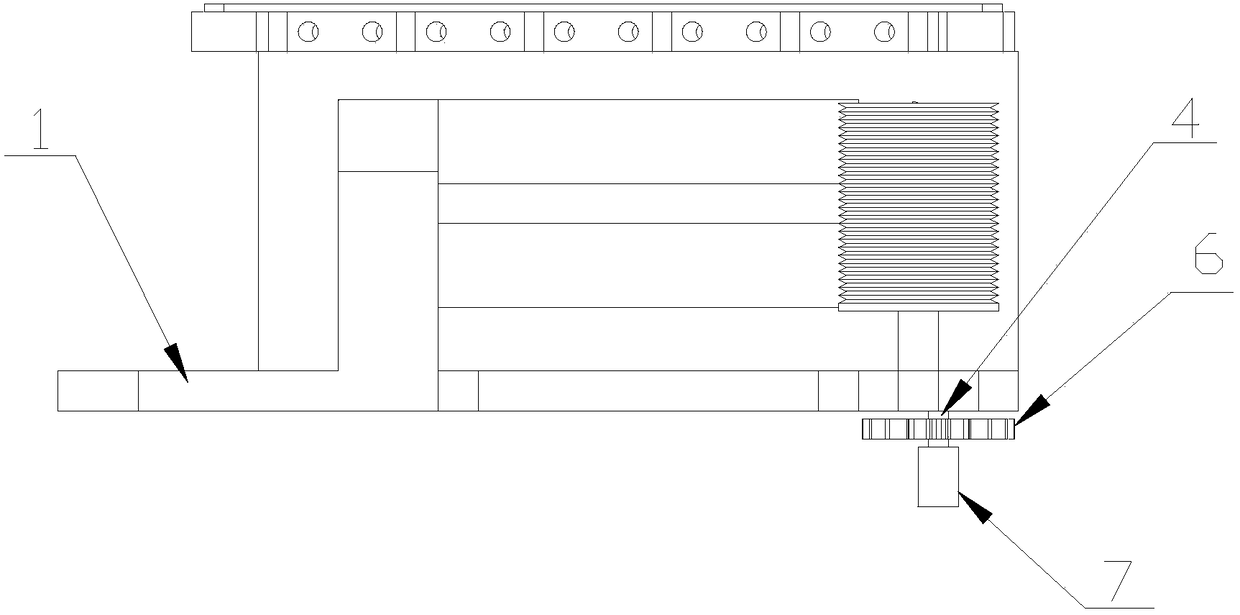

Test sleeve for GIS terminal test device

ActiveCN104698356AThe electric field distribution is the sameImprove accuracyTesting dielectric strengthEngineeringHigh pressure

The invention provides a test sleeve for a GIS terminal test device, and aims at testing a GIS terminal. The sleeve comprises an insulation barrel body, a high pressure import mechanism, a grounding shielding electrode and a grounding flange; the grounding flange is connected with one end of the insulating barrel body; the high pressure import mechanism is connected with the other end of the insulating barrel body; the ground shielding electrode is arranged on the inner wall of the insulating barrel body and connected with the grounding flange; a testing cavity in which the GIS terminal extends is formed in one end of the insulating barrel body, connected with the grounding flange and toward the other end of the insulating barrel; when in work, the testing cavity forms a closed testing cavity. The sleeve is safe, reliable, small in size, simple in structure, and convenient to mount and use; the completion pressure test can be carried out for the GIS terminal and a cable circuit; the accuracy, efficiency and reliability of test can be effectively improved; the test sleeve is suitable for wide popularization and application.

Owner:GUANGDONG WEIHENG POWER TRANSMISSION & DISTRIBUTION ENG +1

Gypsum-based heat-conducting self-leveling mortar as well as preparation method and application thereof

The invention discloses gypsum-based heat-conducting self-leveling mortar as well as a preparation method and application thereof. Raw materials for preparing the gypsum-based heat-conducting self-leveling mortar comprises phosphogypsum, papermaking white mud and a heat-conducting material, and does not comprise cement. The preparation method comprises the following steps of: mixing the phosphogypsum with the papermaking white mud, performing calcining and ball-milling; and mixing the ball-milled phosphogypsum and papermaking white mud with the heat conducting material, aggregate, a retarder,a defoaming agent, a water retaining agent, a water reducing agent and redispersible latex powder. The gypsum-based heat-conducting self-leveling mortar provided by the invention has good fluidity andheat conductivity, can be used for gap filling and upper-layer covering of floor heating pipelines, greatly saves the raw material cost of a floor heating system, and realizes resource reutilizationof two solid wastes, i.e., the phosphogypsum and papermaking white mud.

Owner:CHINA NAT BUILDING MATERIALS TECHCAL INNOVATION & RES INST LIMITED

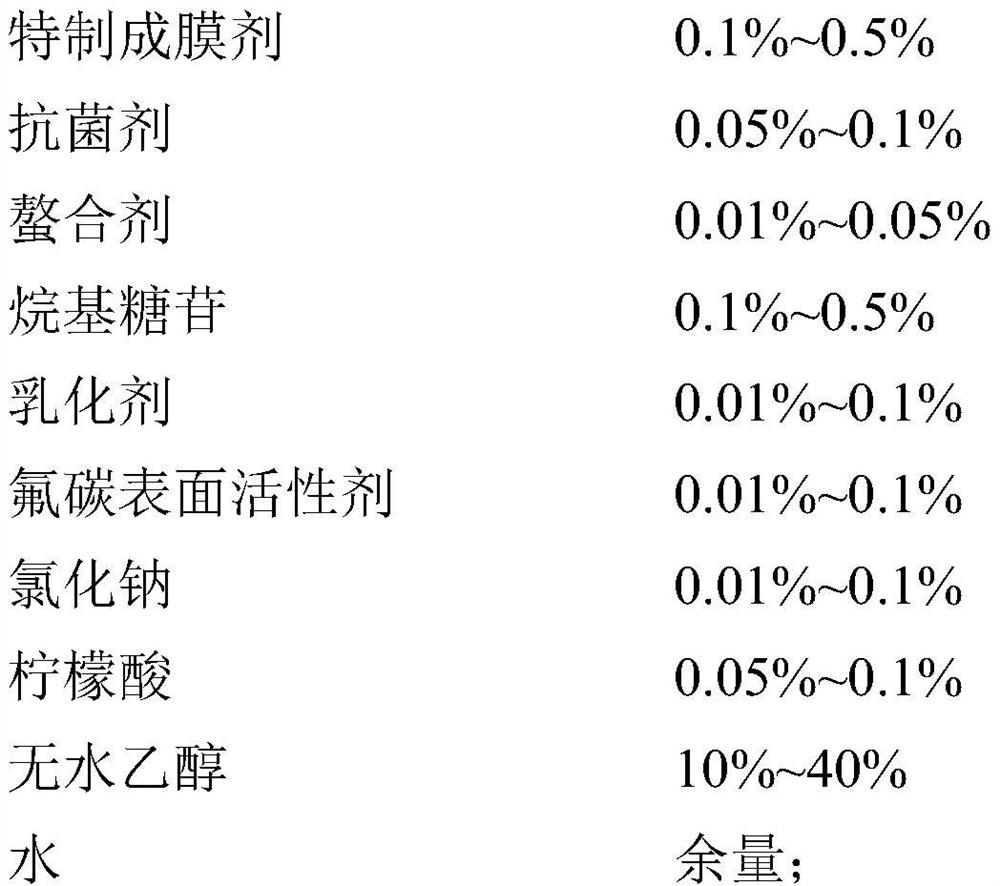

Antibacterial antifogging agent, and antibacterial long-acting antifogging wet tissue prepared from same

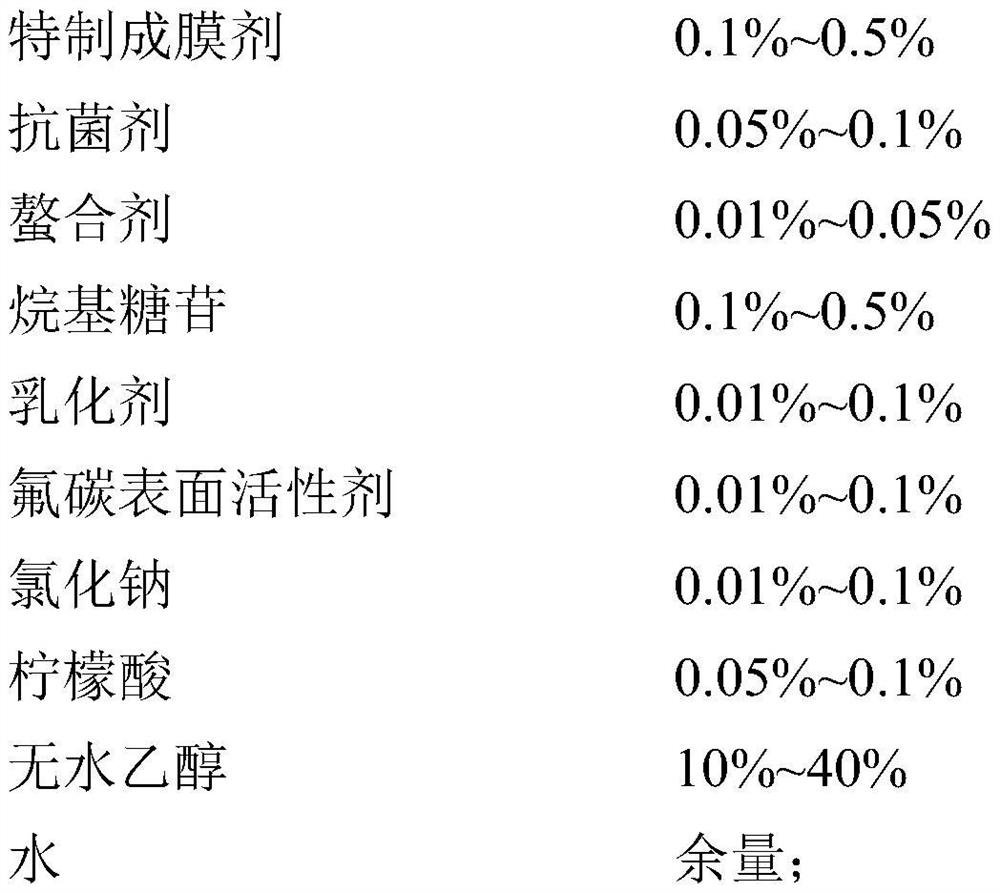

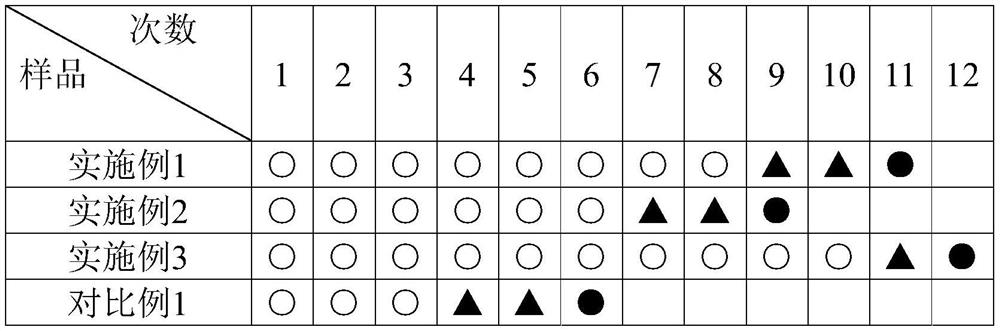

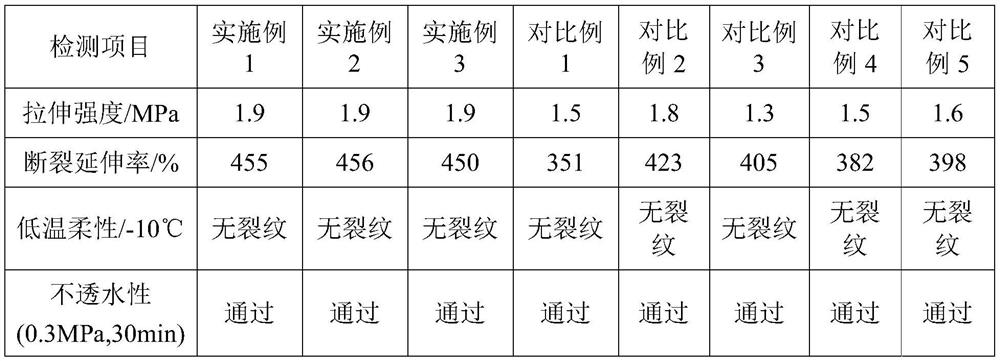

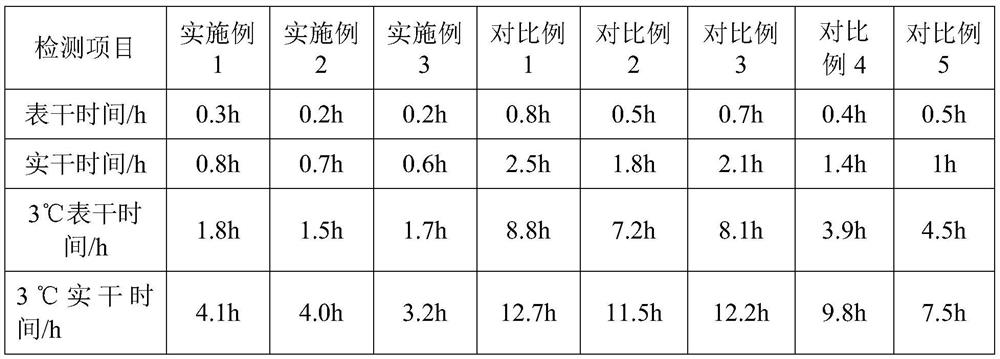

ActiveCN113105868AReduce migration rateReduce churn rateBiocideOther chemical processesNaCl - Sodium chlorideActive agent

The invention discloses an antibacterial antifogging agent, and an antibacterial long-acting antifogging wet tissue prepared from the same. The antibacterial long-acting antifogging wet tissue is prepared from, by mass, 0.1-0.5% of a special film forming agent, 0.05-0.1% of an antibacterial agent, 0.01-0.05% of a chelating agent, 0.1-0.5% of alkyl glycoside, 0.01-0.1% of an emulsifier, 0.01-0.1% of a fluorocarbon surfactant, 0.01-0.1% of sodium chloride, 0.05-0.1% of citric acid, 10-40% of absolute ethyl alcohol, and the balance of water. The product prolongs the antifogging time to a great extent, and is suitable for various types of lenses.

Owner:江苏南创化学与生命健康研究院有限公司 +2

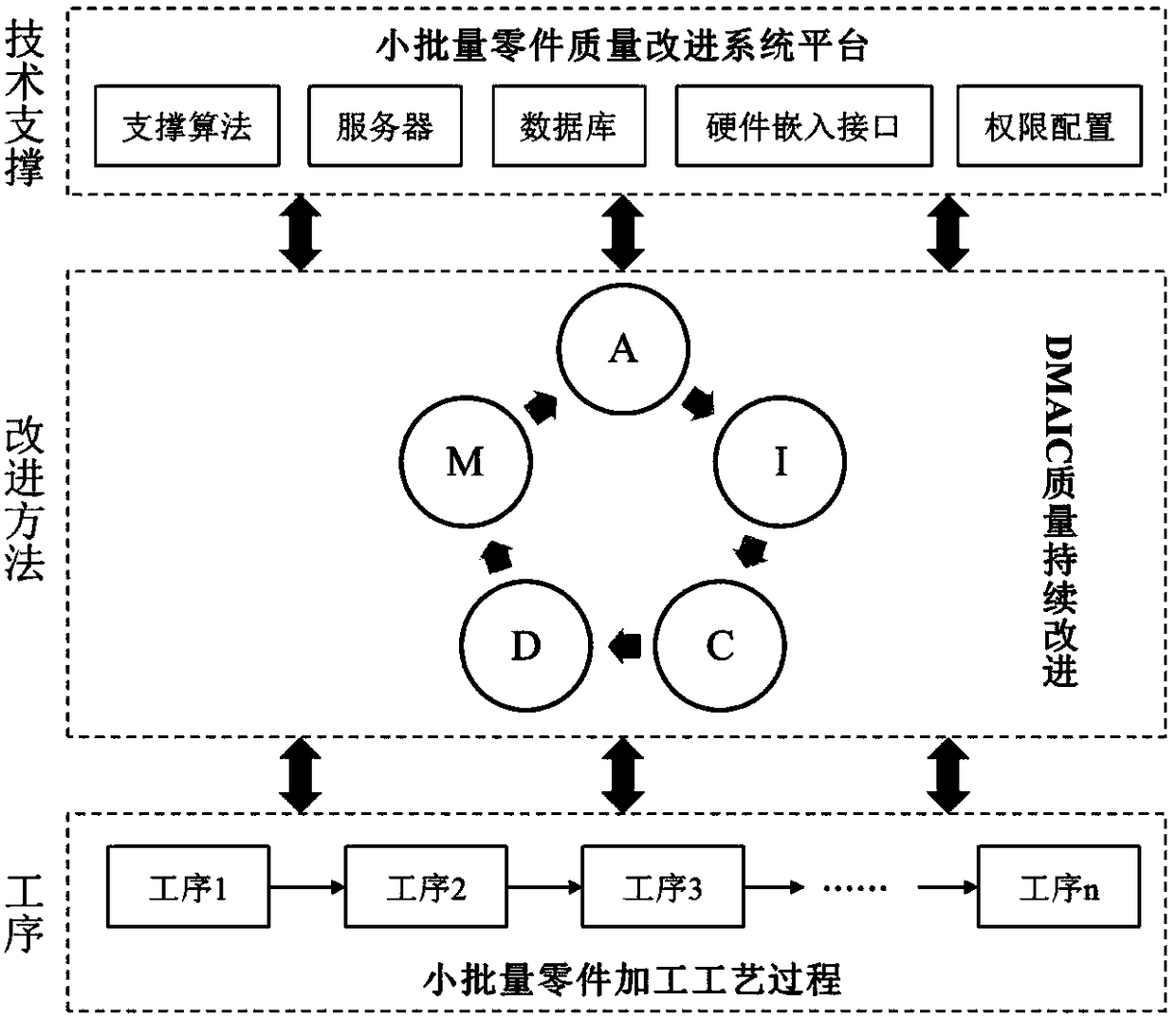

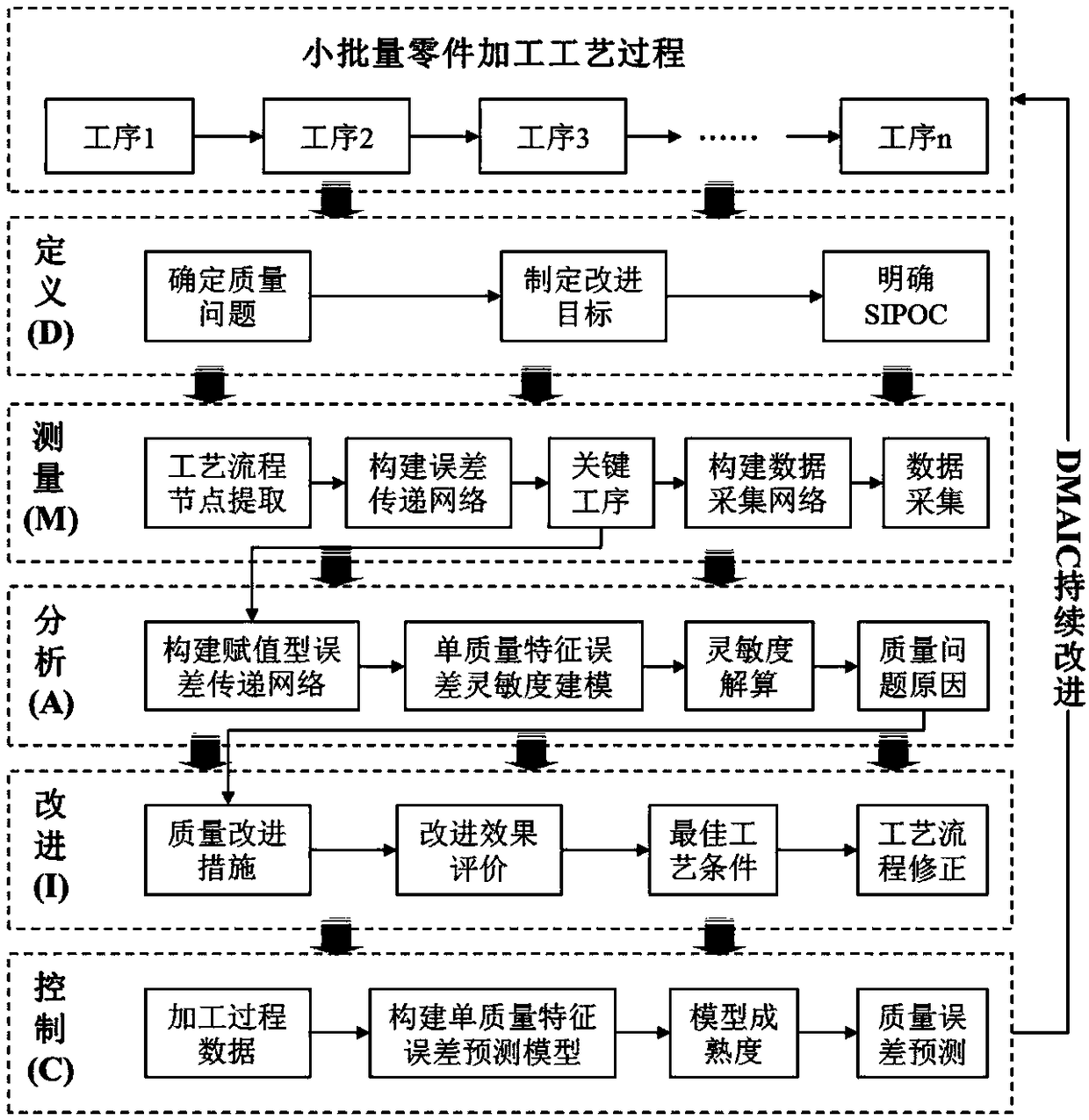

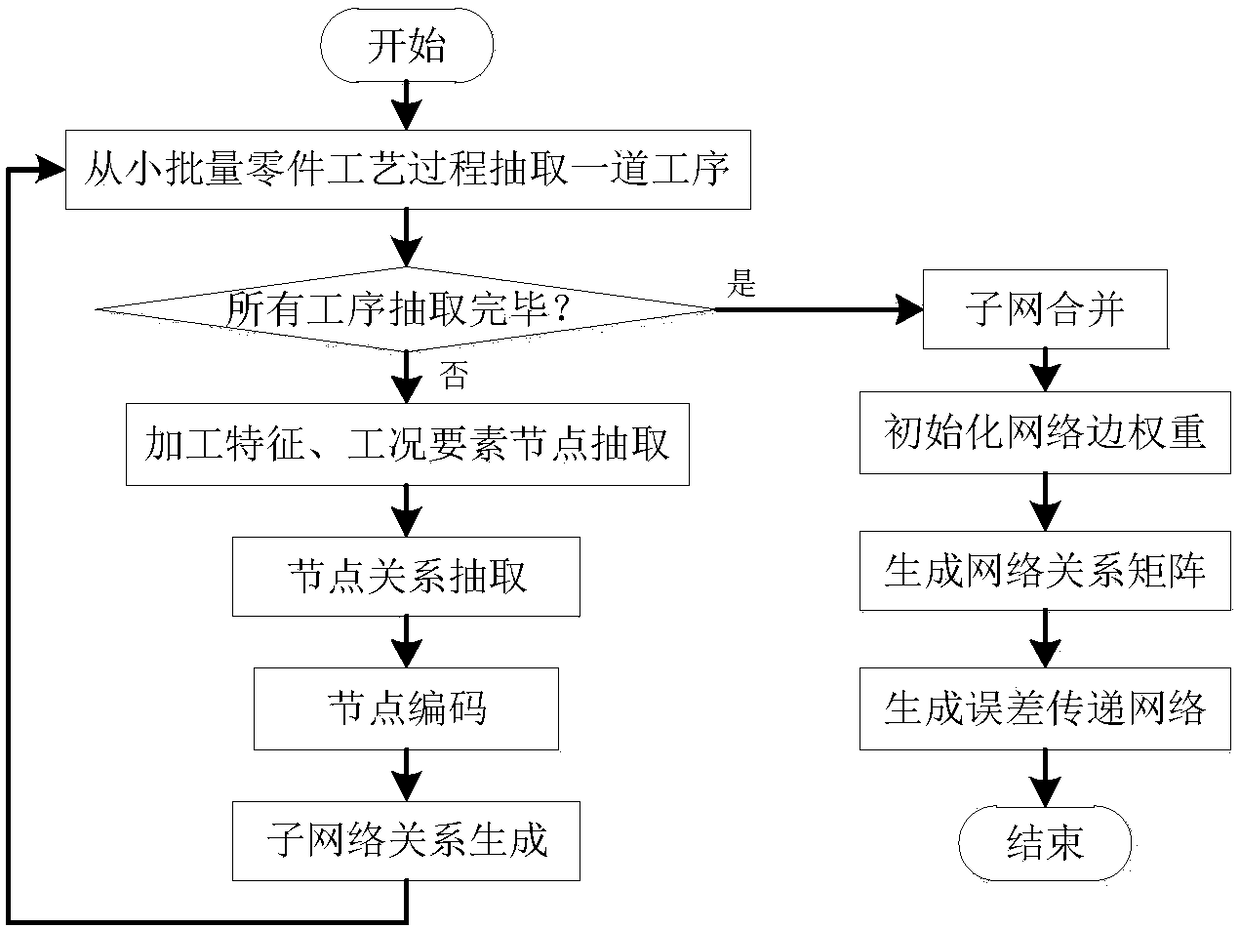

DMAIC-driven small-batch part processing technique process quality improvement method

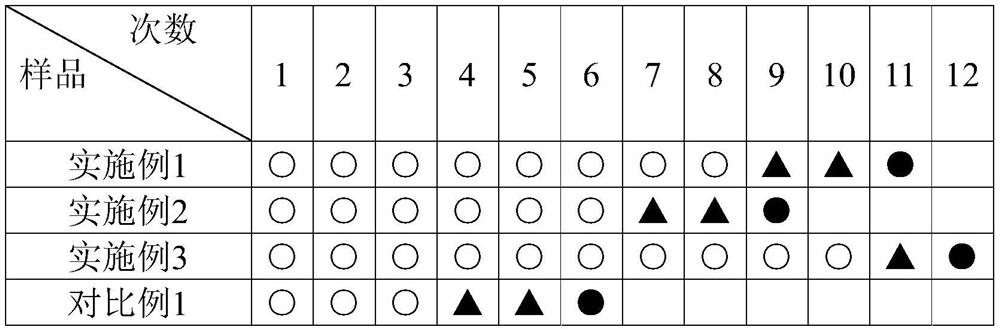

ActiveCN108563201ASolving Quality Improvement IssuesThe solution cannot be appliedTotal factory controlProgramme total factory controlProcess qualityContinual improvement process

The invention relates to a DMAIC-driven small-batch part processing technique process quality improvement method. The logic process of the method mainly comprises five stages, namely, a definition stage, a measurement stage, an analysis stage, an improvement stage and a control stage. The definition stage is to mainly determine the object and target of a quality improvement activity, and find outall factors related to a processing process; the measurement stage is to determine the key control procedures of the processing process, builds a CPS-based digital information acquisition network, andacquires processing data in a production process in real time; the evaluation stage is to construct an assignment type error transmission network, calculate the sensitivity of quality feature error to find out key factors related to a quality problem; the improvement stage is to formulate corresponding measures to improve process parameters and the like according to reasons for the quality problem; and the control stage is to construct a quality feature error prediction model to effectively control product quality. With the method adopted, the processing technique process of small batch partscan be effectively improved and optimized, and a function for continuously improving the processing process quality of the small batch parts can be formed.

Owner:XI AN JIAOTONG UNIV

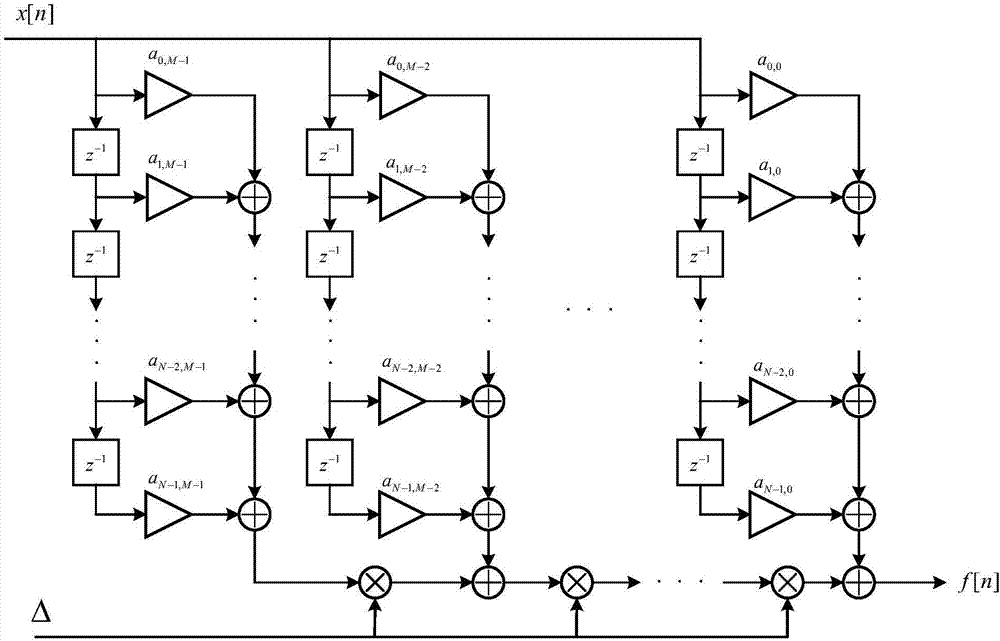

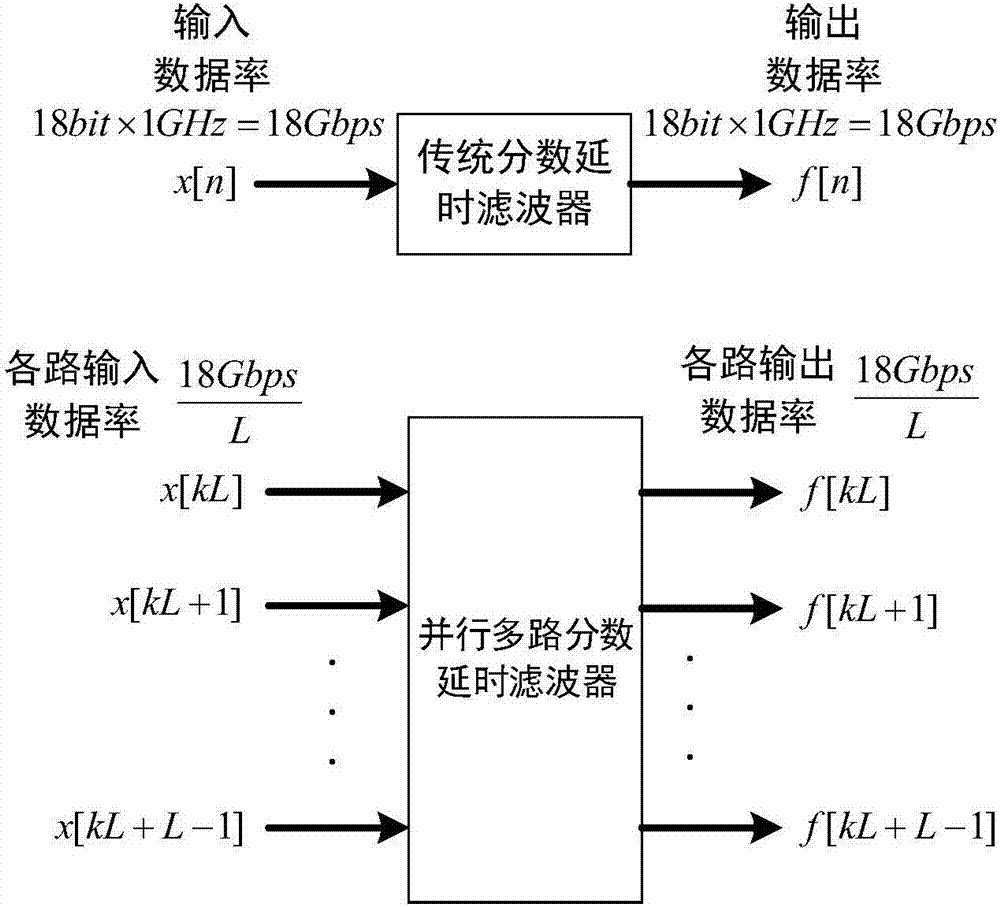

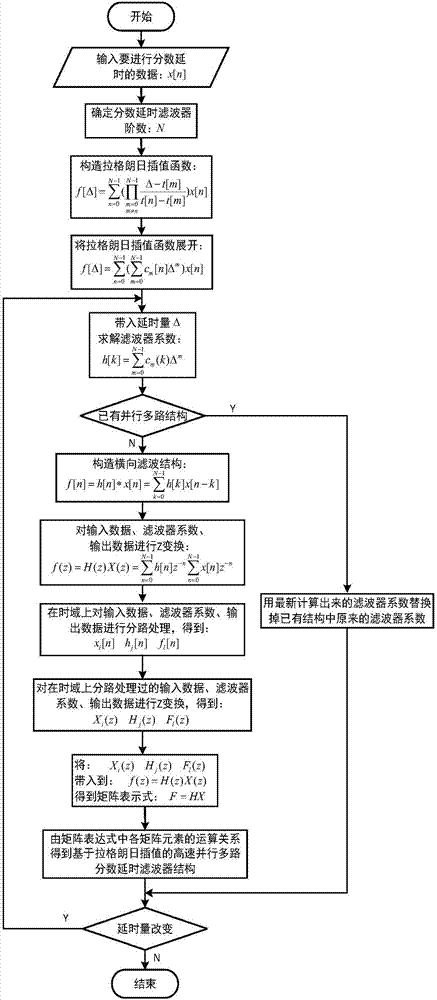

High-speed parallel multi-path fractional delay filter implementation method

ActiveCN107332539AThe solution cannot be appliedSimplify the process of solving for filter coefficientsDigital technique networkComputational scienceFractional delay filter

The invention belongs to the technical field of communication, and relates to a high-speed parallel multi-path fractional delay filter implementation technology based on Lagrange interpolation. According to the invention, a fractional delay filter can be applied under the high-speed parallel multi-path condition and meanwhile, by using a Lagrange interpolation algorithm, the process of solving a filter coefficient is simplified. The high-speed parallel multi-path fractional delay filter implementation technology based on Lagrange interpolation, which is disclosed by the invention, is suitable to implement in high-speed platform, such as a FPGA, a DSP and the like, and is convenient for practical application.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

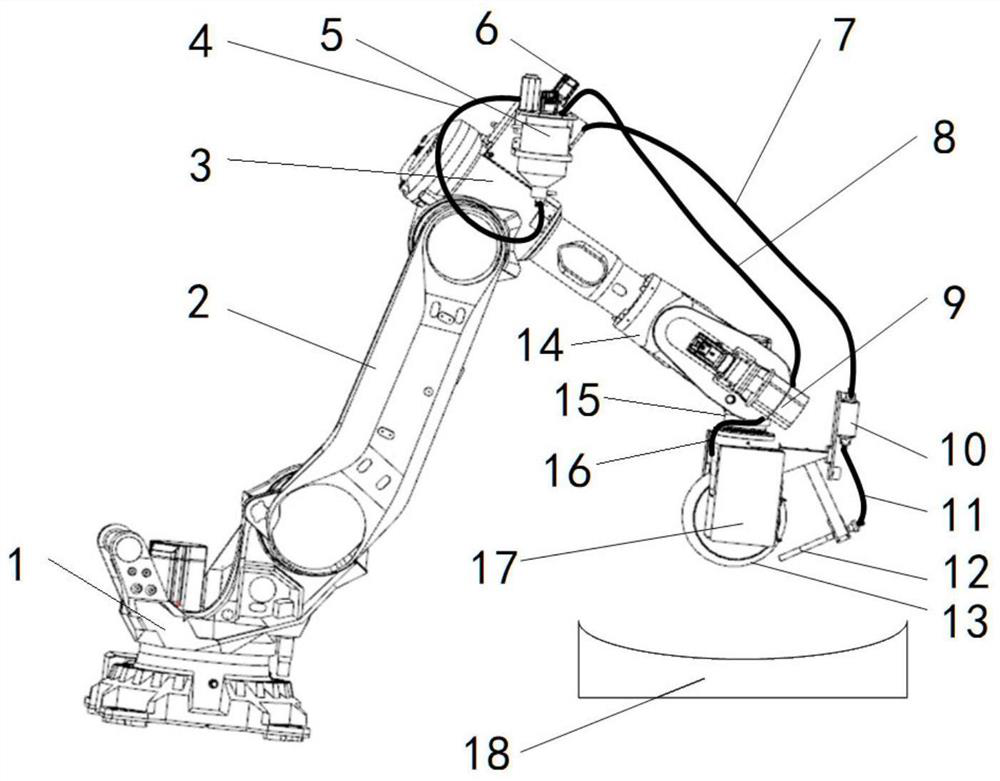

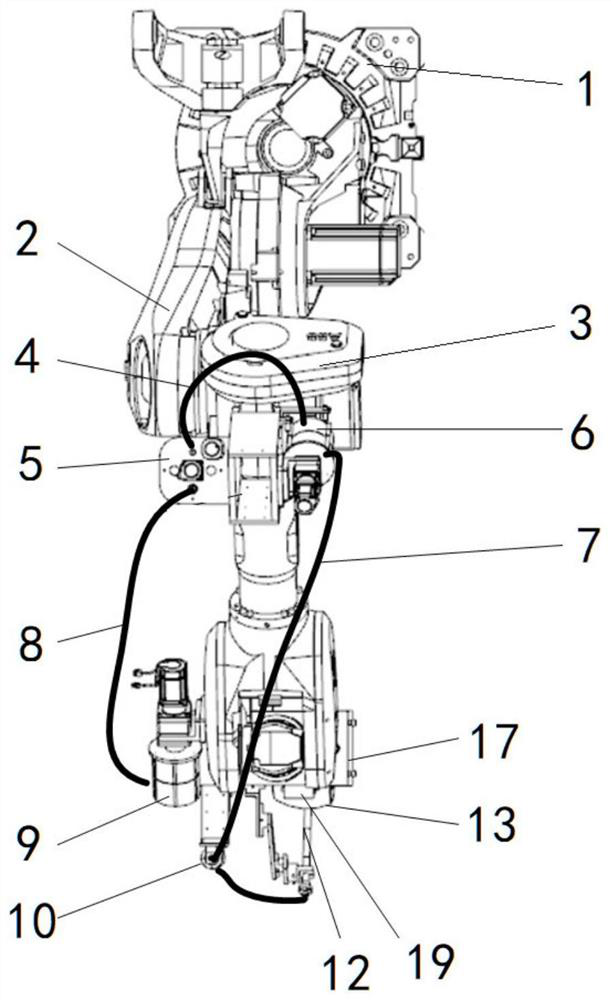

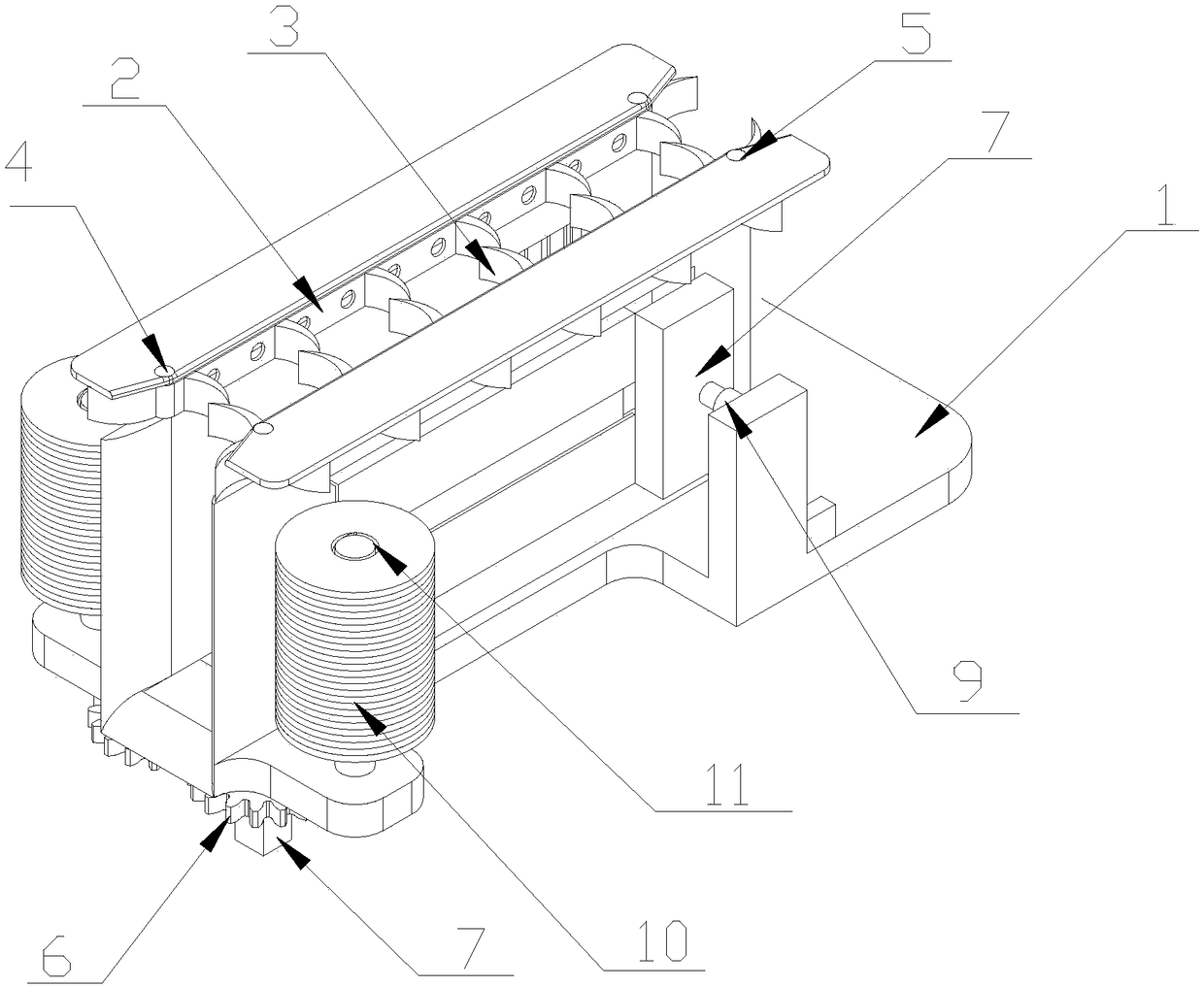

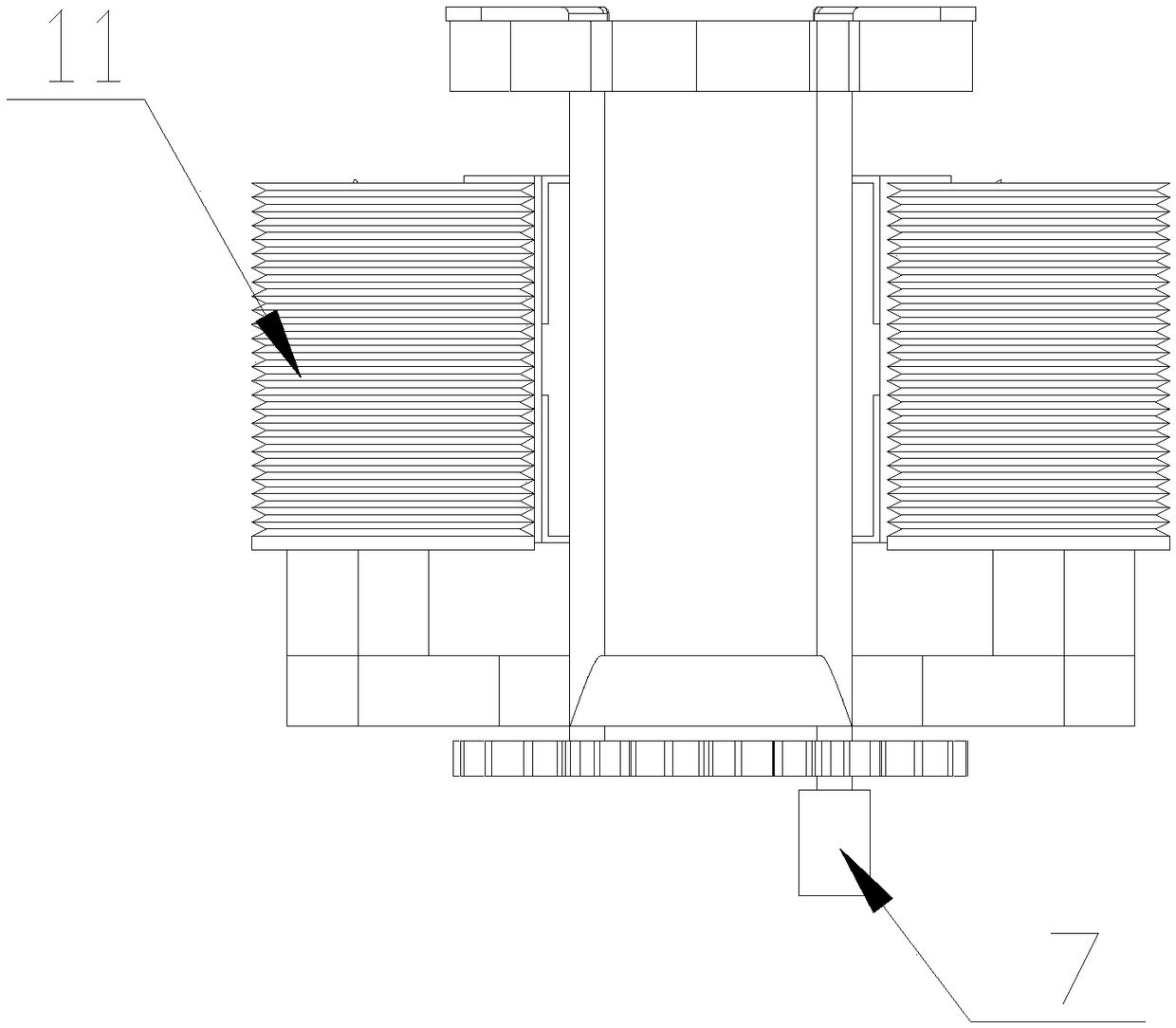

Magneto-rheological polishing machining system based on mechanical arm

ActiveCN113352152ACyclic stabilityThe solution cannot be appliedOptical surface grinding machinesGrinding feed controlPolishingLiquid storage tank

The invention discloses a magneto-rheological polishing machining system based on a mechanical arm. The magneto-rheological polishing machining system comprises the mechanical arm with multiple joints connected in series and a magneto-rheological fluid circulating system distributed on the mechanical arm. The magneto-rheological fluid circulating system comprises a recovery pump arranged on the first joint, a liquid storage tank, a supply pump, a magnetic field generating device, a polishing wheel, a nozzle, a damper and a recoverer, wherein the liquid storage tank and the supply pump are arranged on the second joint, and the magnetic field generating device, the polishing wheel, the nozzle, the damper and the recoverer are arranged on the tail end joint; and the magneto-rheological fluid circulating system further comprises a first supply pipe connected with the liquid storage tank and a supply pump head, a second supply pipe connected with the supply pump and the damper, a third supply pipe connected with the damper and the nozzle, a first recovery pipe connected with the recoverer and the recovery pump, and a second recovery pipe connected with the recovery pump and the liquid storage tank. The magneto-rheological fluid circulation system is divided into sub-components, and the sub-components of the magneto-rheological fluid circulation system are arranged on the mechanical arm in a distributed layout manner by combining the characteristics of the mechanical arm and the magneto-rheological fluid circulation system.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

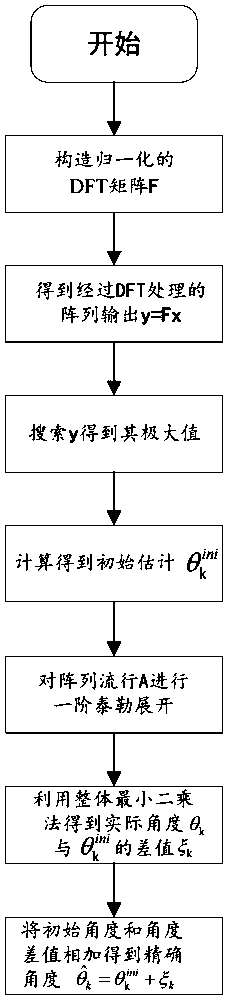

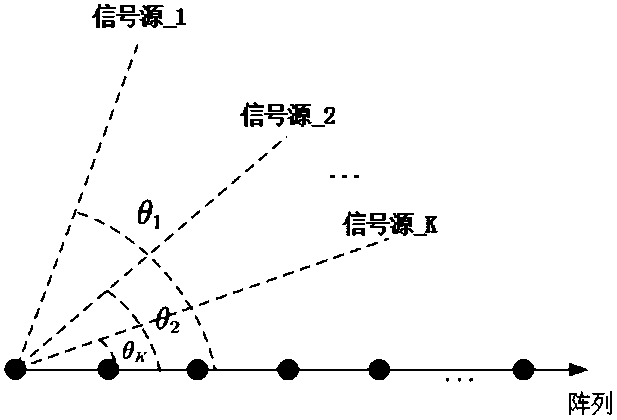

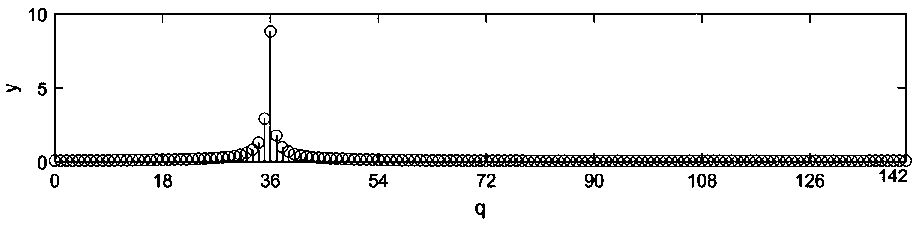

DOA estimation method based on DFT enhancement in large-scale array

ActiveCN111413668ASolve complexityThe solution cannot be appliedRadio wave direction/deviation determination systemsTarget signalReal signal

A DOA estimation method based on DFT enhancement in a large-scale array obtains accurate estimation of DOA through combination of DFT and a Taylor expansion algorithm, and comprises the following steps: firstly, for a space signal received by a large-scale antenna array, obtaining initial DOA estimation of the signal through DFT; then, on the basis of obtaining the initial angle, carrying out first-order Taylor series expansion on the array direction matrix at the initial angle, and obtaining a difference value between a real signal angle and the initial angle by utilizing an overall least square method; and finally, adding the difference value to the initial angle to obtain an accurate DOA estimation angle. According to the invention, the characteristics of DFT, Taylor series expansion and large-scale antenna array are ingeniously combined; the technical bottleneck that a traditional subspace algorithm needs huge complexity and is not easy to apply practically when applied to a large-scale antenna array is broken through, the target signal angle can be estimated more quickly and accurately, the operation cost is low, the effect is good, and engineering implementation is easy.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

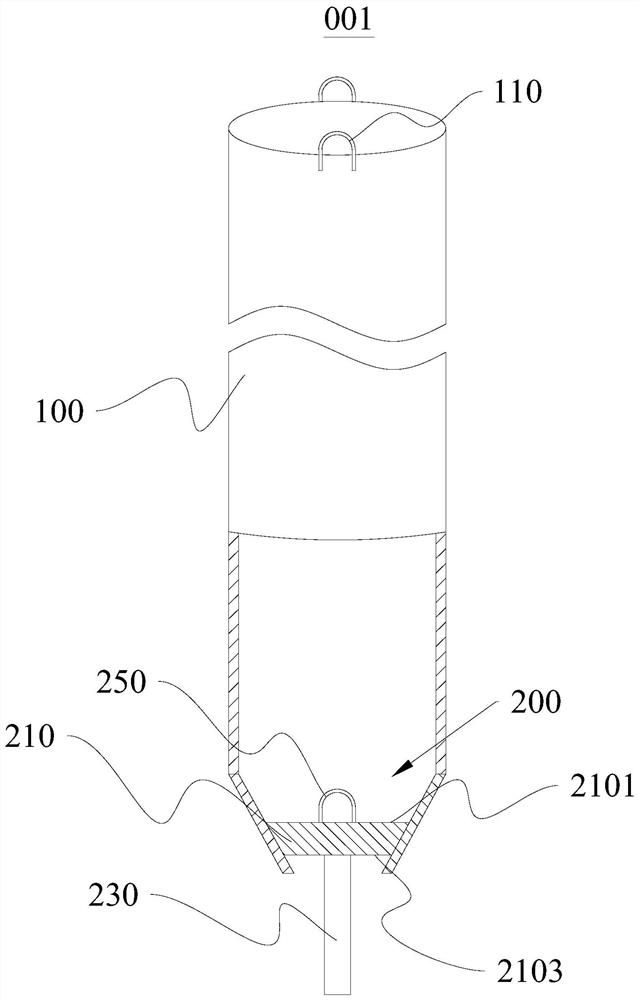

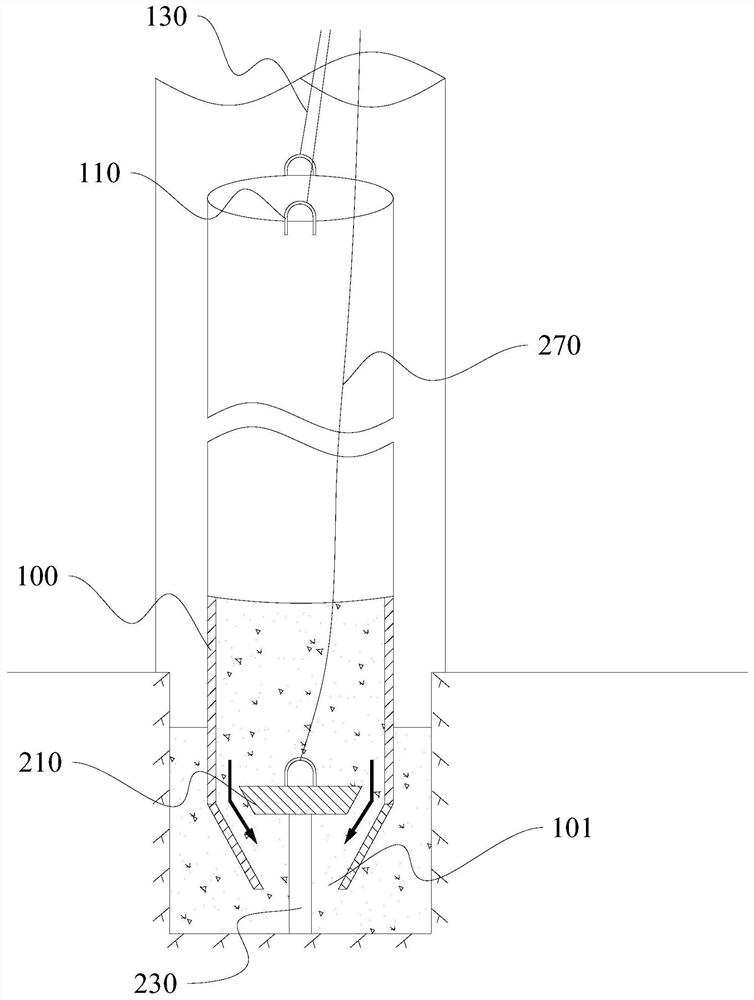

Underwater concrete pouring device in steel pipe and concrete pouring method

The invention provides an underwater concrete pouring device in a steel pipe and a concrete pouring method, and belongs to the field of concrete pouring. The underwater concrete pouring device is usedfor underwater concrete pouring of the steel pipe of a deep water lock catch steel pipe pile cofferdam and comprises a container pipe and a blocking part. A reduced concrete outlet is formed in one end of the container pipe. The blocking part comprises a conical plate, the conical plate is provided with a small end face and a large end face which are oppositely arranged, and the small end face ofthe conical plate faces the concrete outlet and is used for blocking the concrete outlet. The small end face is further fixedly provided with a steel bar stretching out of the concrete outlet. By means of the underwater concrete pouring method in the steel pipe, the problem that an existing conventional underwater concrete pouring process cannot be suitable for concrete pouring in the small-aperture steel pipe pile of the deep water lock catch steel pipe pile cofferdam can be solved. The underwater concrete pouring device in the steel pipe is simple in structure, easy to machine, convenient to construct and operate and reliable in pouring quality, and the problem that the conventional process cannot be suitable for underwater concrete pouring is ingeniously solved.

Owner:CHINA MCC5 GROUP CORP

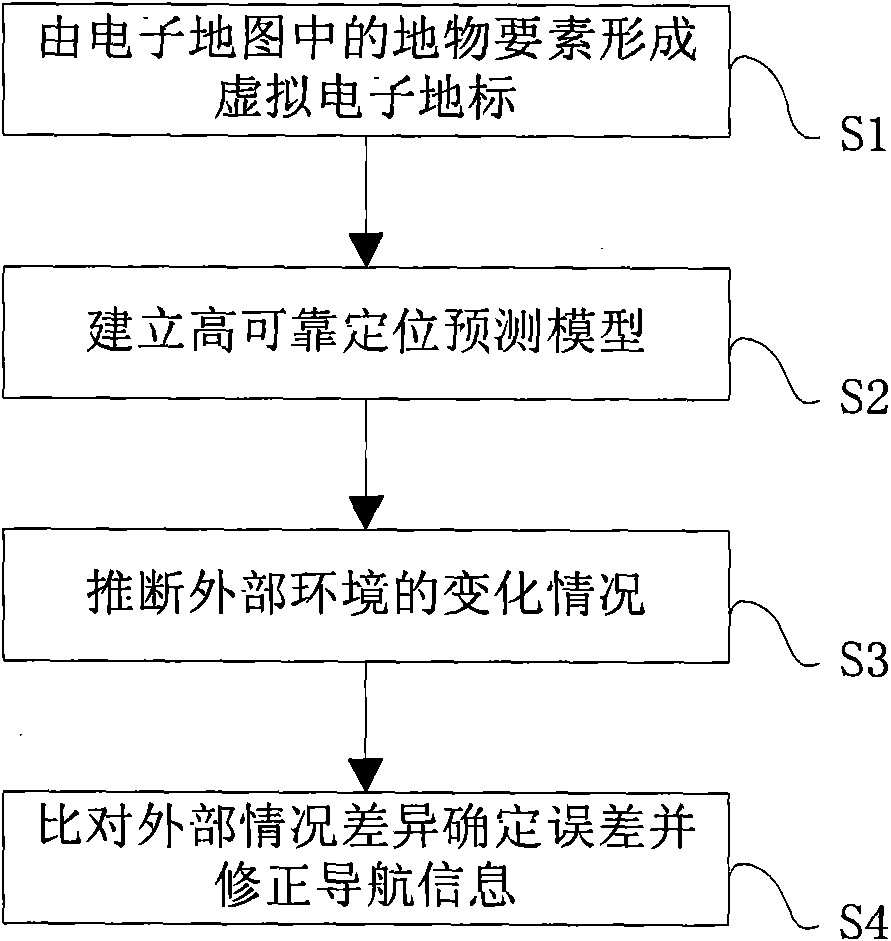

Highly reliable positioning prediction method and system based on virtual landmarks

ActiveCN103728635AThe solution cannot be appliedReduce workloadSatellite radio beaconingTerrainPositioning technology

The invention relates to the technical field of satellite positioning, and discloses a highly reliable positioning prediction method and system based on virtual landmarks. The method includes the steps that surface feature elements in an electronic map are extracted, arranged and modeled to form the virtual electronic landmarks with accurate coordinates; external perception conditions are used as positioning accuracy impact factors, and according to the weight of influence on positioning accuracy of the factors, a highly reliable positioning prediction model is built; according to current navigation information, the nearby virtual electronic landmarks are searched for in the electronic map, and the virtual electronic landmarks are substituted into the prediction model to deduce the change situation of the external environment at a next moment; when the next moment comes, external perception information is collected, the external perception information is compared with the deduced change situation, comparison differences are substituted into the prediction model again, backward induction is performed to determine errors of the navigation information, and accordingly follow-up navigation information is corrected. By the utilization of the virtual landmarks, the highly reliable positioning prediction method and system achieve map matching feedback and assistant positioning and solve the problem that a highly reliable positioning prediction method and system cannot be used in a wide-range area or complex terrain environment.

Owner:苍穹数码技术股份有限公司 +1

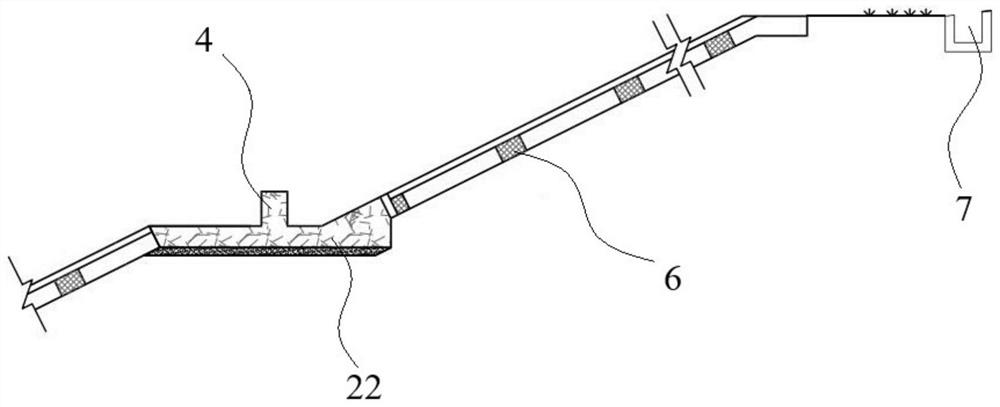

Dynamic compaction side slope and dynamic compaction side slope construction method

PendingCN114439020AThe solution cannot be appliedAvoid poor slope stabilityExcavationsSewer pipelinesGeotechnical engineeringStructural engineering

The invention discloses a dynamic compaction side slope construction method which comprises a first side slope layer, at least one second side slope layer and a third side slope layer, the second side slope layer is arranged below the first side slope layer and obtained through excavation treatment of the first side slope layer, and the third side slope layer is arranged below the second side slope layer and obtained through excavation treatment of the third side slope layer. The second side slope layer is subjected to excavation treatment, so that a special high excavation road section which is suitable for side slope excavation soil layers and is mainly miscellaneous fill and plain fill is formed. The method can be used for solving the problem that a cutting slope protection structure and a construction method in the prior art cannot be completely applicable.

Owner:中冶华成(武汉)工程有限公司

Low-damage green leaf vegetable bundling device and bundling method

PendingCN108163247AAvoid damageSolve the labor forcePackaging automatic controlBundling machine detailsLeafy vegetablesEngineering

The invention relates to a low-damage green leaf vegetable bundling device and a bundling method. The device includes a frame, a seeding pulling device, a heat sealing device and a control device. Theframe is used for supporting and fixing other devices; the seeding pulling device is used for collecting and stirring leafy vegetables; the heat sealing device is used for bundling the collected leafvegetables by heat sealing; the control device is used for controlling the temperature of a heat sealing strip, the speed of a pushing rod and the weight of spinach bundled. Aiming at the difficulties of bundling and harvesting of the green leafy vegetables, the low-damage green leaf vegetable bundling device is provided, and the device is of great significance for the bundling and harvesting operation of the widely planted green leafy vegetables, and better overcomes the problem of bundling damage.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

A kind of preparation method of super absorbent proton exchange membrane

ActiveCN104078691BImprove conductivityHigh mechanical strengthFuel cellsMicrospherePhysical chemistry

The invention discloses a preparation method of a superabsorbent proton exchange membrane, which comprises the following steps: (1) preparing hollow mesoporous silica microspheres and fluorine-type perfluorosulfonic acid polymers according to a mass ratio of 1:9-99 Stir and mix to obtain a mixture; (2) Add the mixture obtained in step (1) to an extruder for melt extrusion to form a film. The temperature of the casting head is 180-200°C, the screw speed is 20-35r / min, The linear speed of the press is 60-100 cm / min; (3) putting the film obtained in step (2) into a sodium hydroxide solution with a concentration of 0.1-1 wt% for 4-12 hours, and the soaking temperature is 60-80°C, Obtain a sodium-form perfluorosulfonic acid film; (4) put the sodium-form perfluorosulfonic acid film obtained in step (3) into hydrochloric acid with a concentration of 0.1 to 1 wt % and soak for 1 to 6 hours at a temperature of 20 to 30° C. , and then washed with deionized water to obtain a superabsorbent proton exchange membrane. Compared with the solution casting method, the superabsorbent proton exchange membrane prepared by the present invention has higher electrical conductivity and mechanical strength.

Owner:JUHUA GROUP TECH CENT

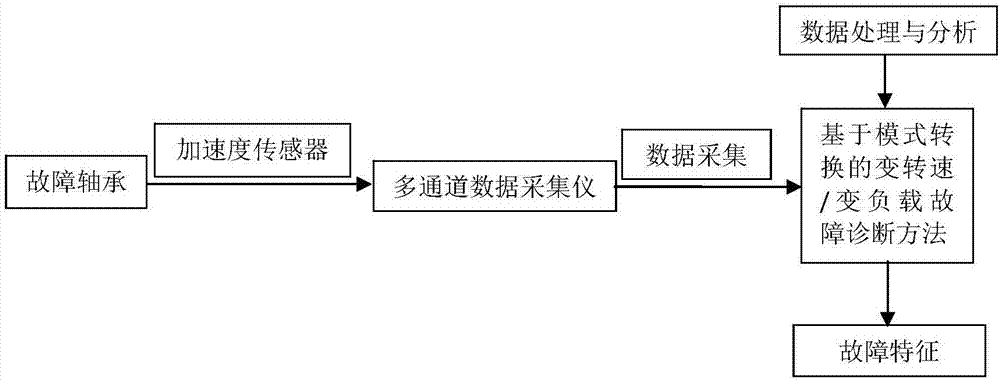

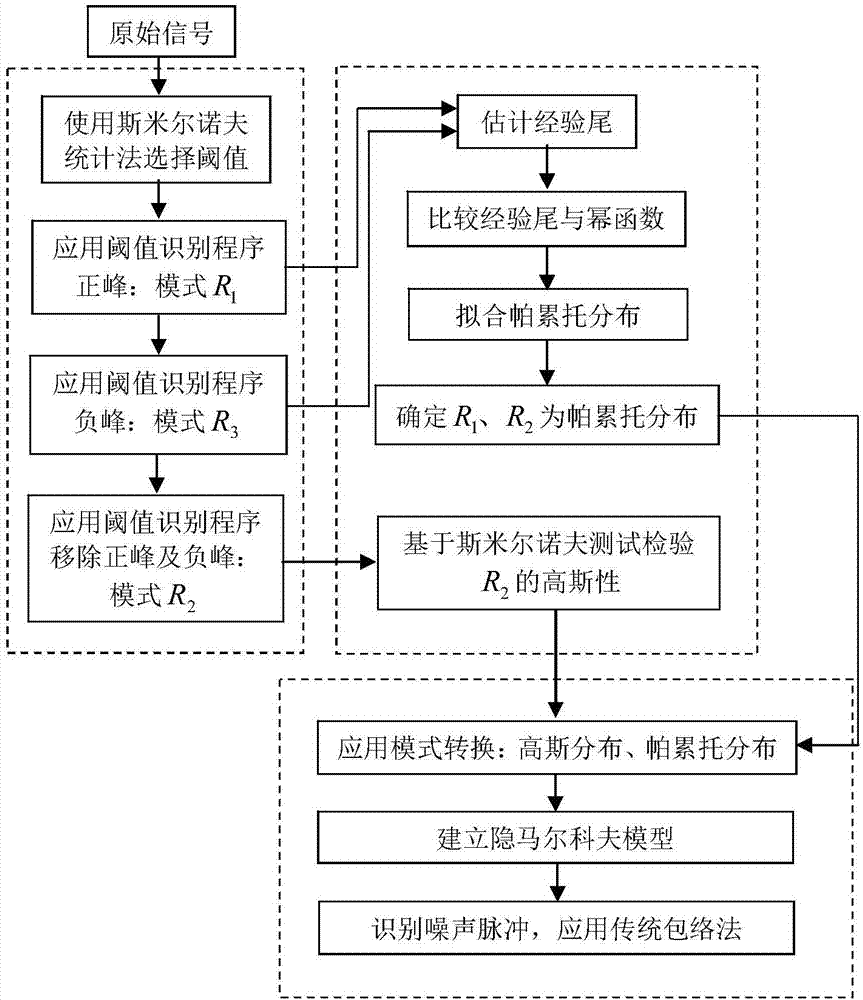

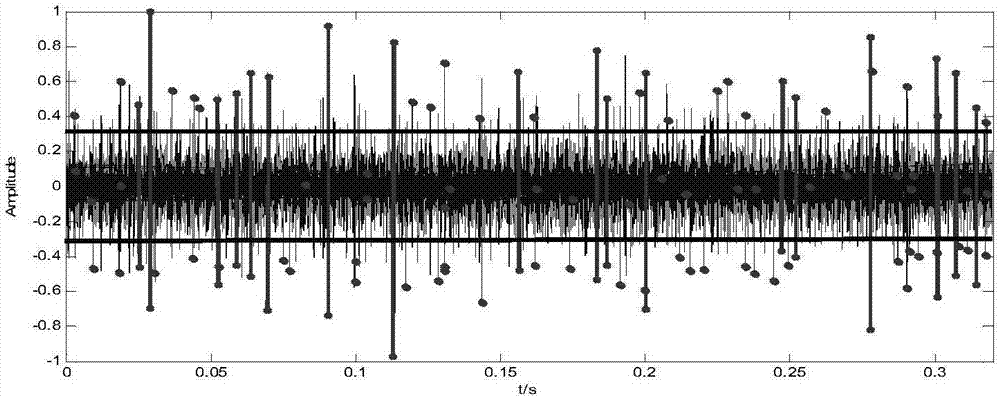

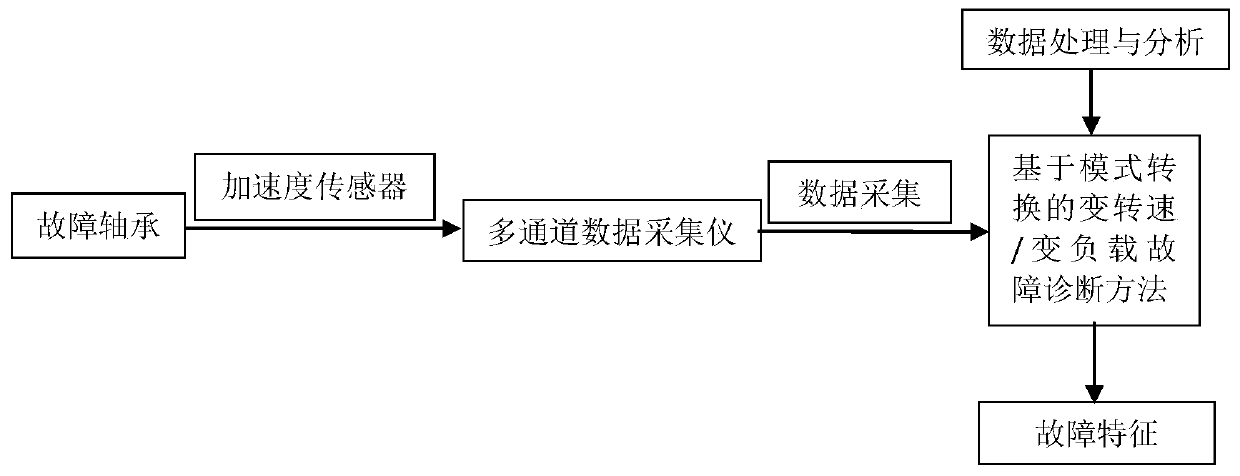

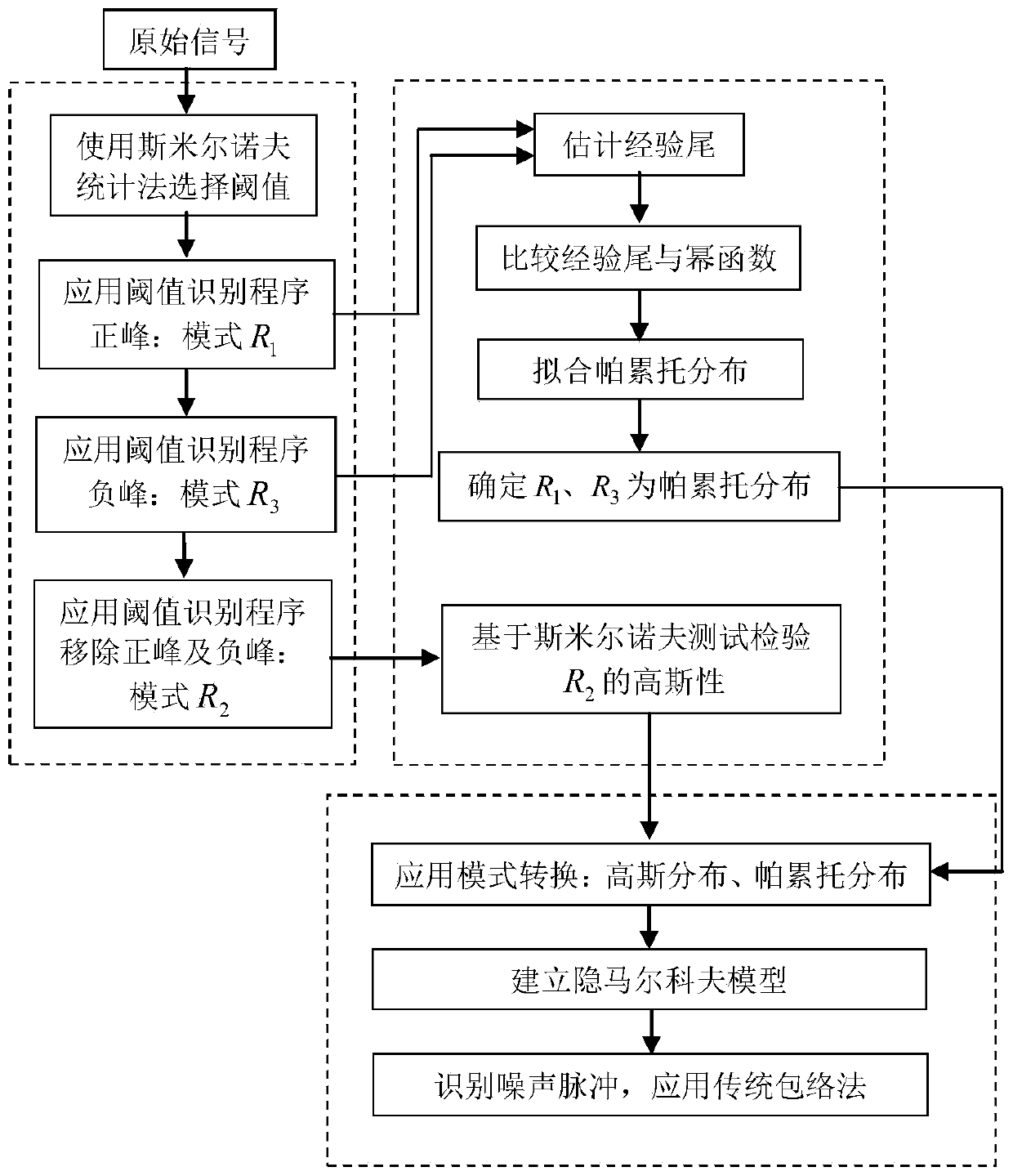

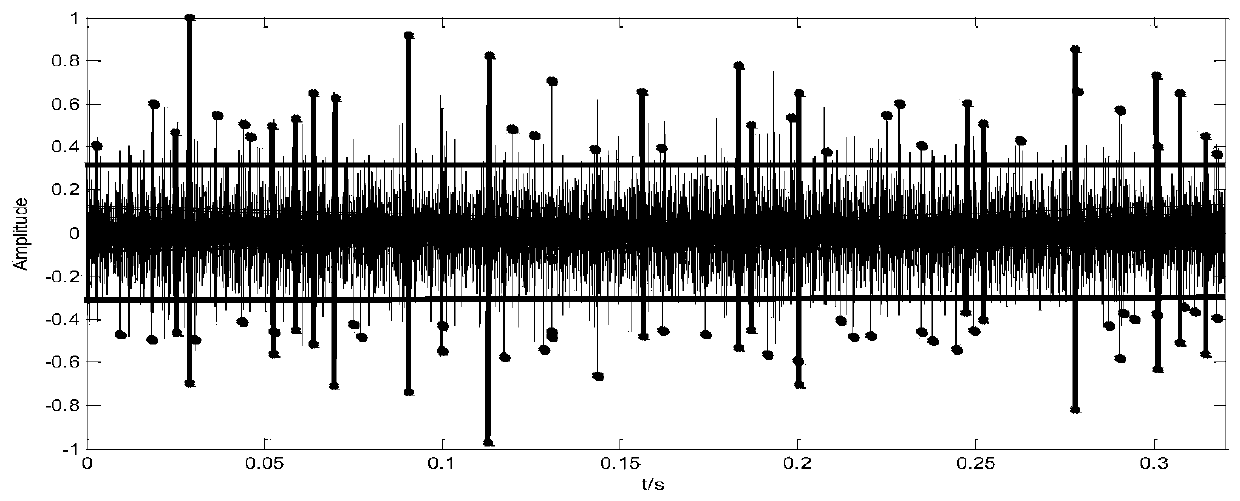

Variable speed/variable load rolling bearing fault diagnosis method based on mode conversion

ActiveCN107884188AImplement fault diagnosisAccurate analysis and processingMachine bearings testingCharacter and pattern recognitionSignal-to-noise ratio (imaging)High energy

The invention discloses a variable speed / variable load rolling bearing fault diagnosis method based on mode conversion. The method comprises the following steps: through assuming that fault rolling bearing vibration signals are at least composed of two signal sources with different distribution characteristics, a bearing vibration signal model is built; based on a threshold technology and a tail estimation method, the signals are preliminarily separated and analyzed to obtain signal modes with different distribution characteristics; an expectation-maximization theory is combined to build a hidden Markov model for the signals to acquire noise pulses, subtraction with original signals is carried out to further improve the signal-to-noise ratio of the signals; and finally, the traditional envelope spectrum is used to analysis the signals, and whether fault happens to the rolling bearing and the type of the fault are evaluated. On one hand, the problem that the vibration signals under a variable speed / variable load condition is hard to diagnose is overcome; and on the other hand, the problem that high-energy pulses change the envelope of the signals and thus, the traditional envelope method can not be applied in a condition of existence of non-Gaussian noise can be solved.

Owner:WENZHOU UNIVERSITY

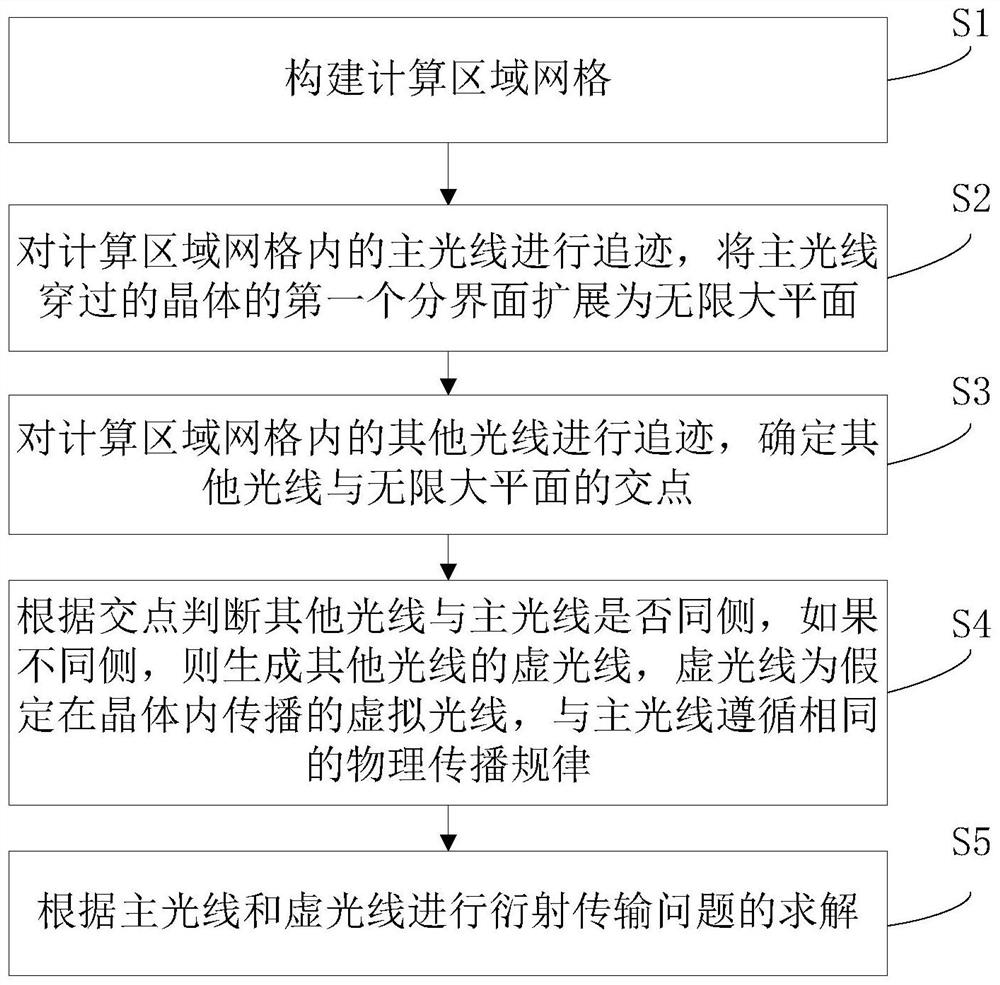

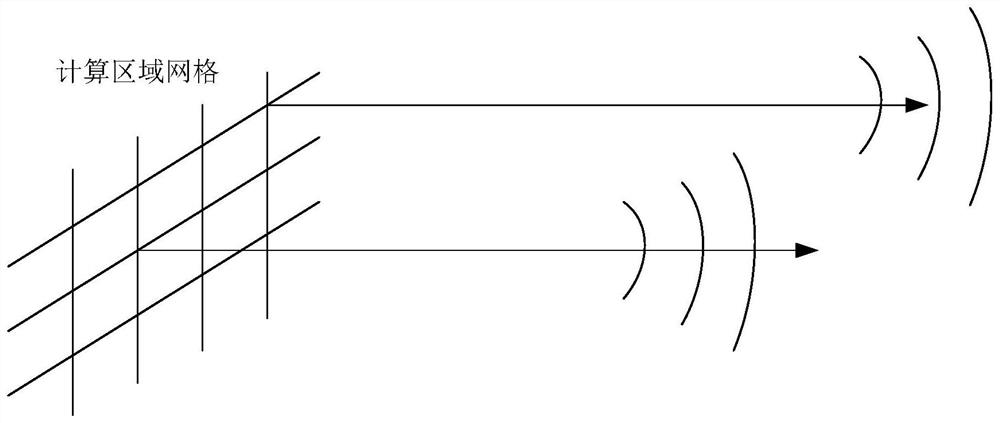

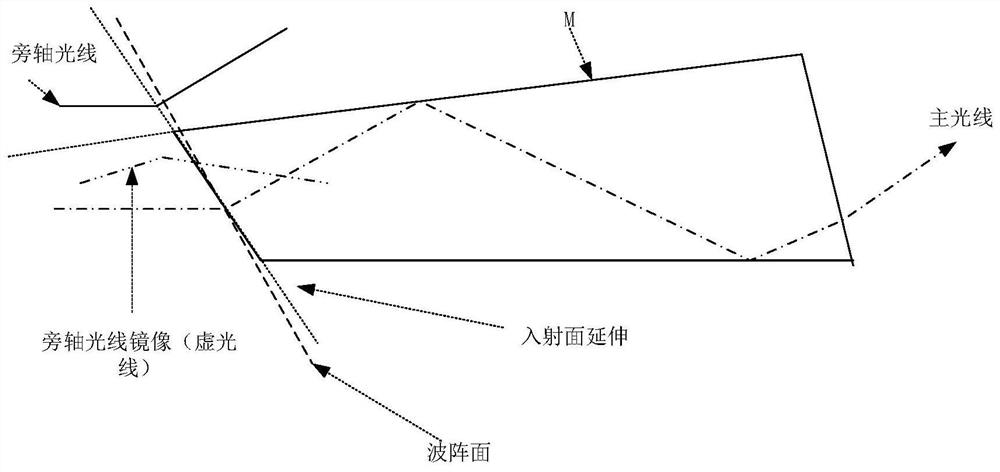

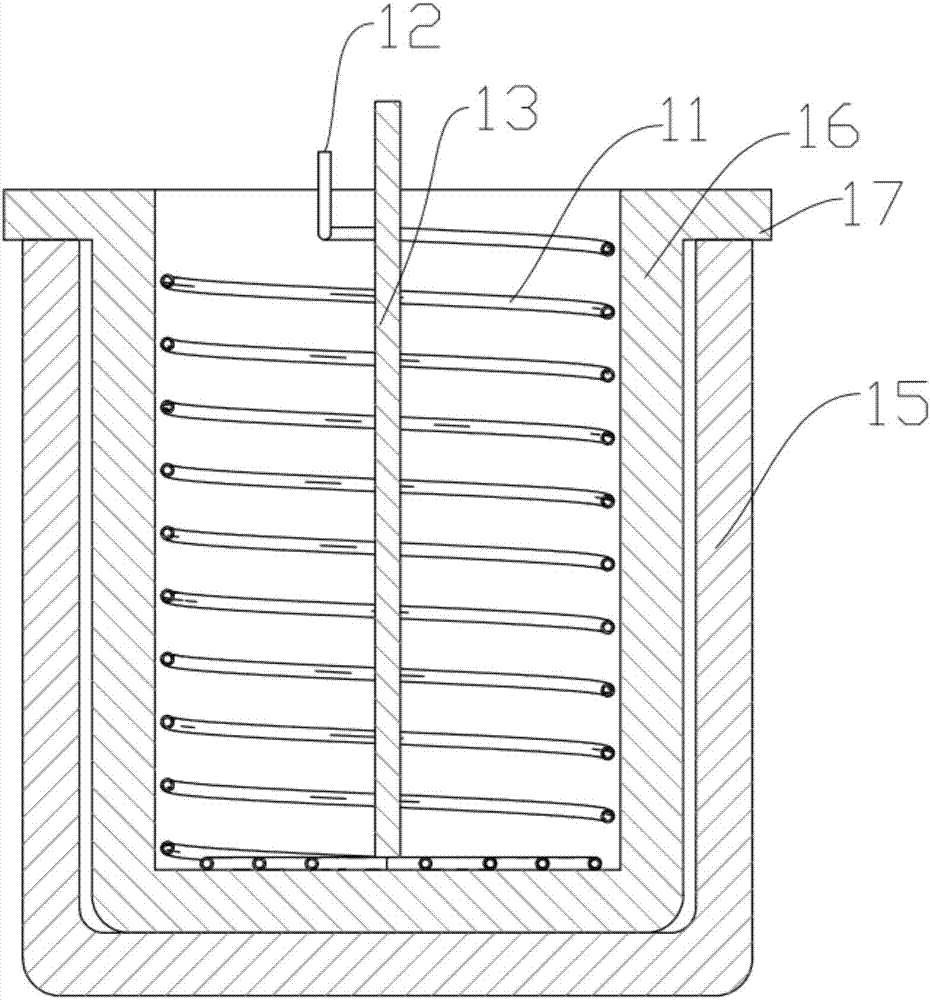

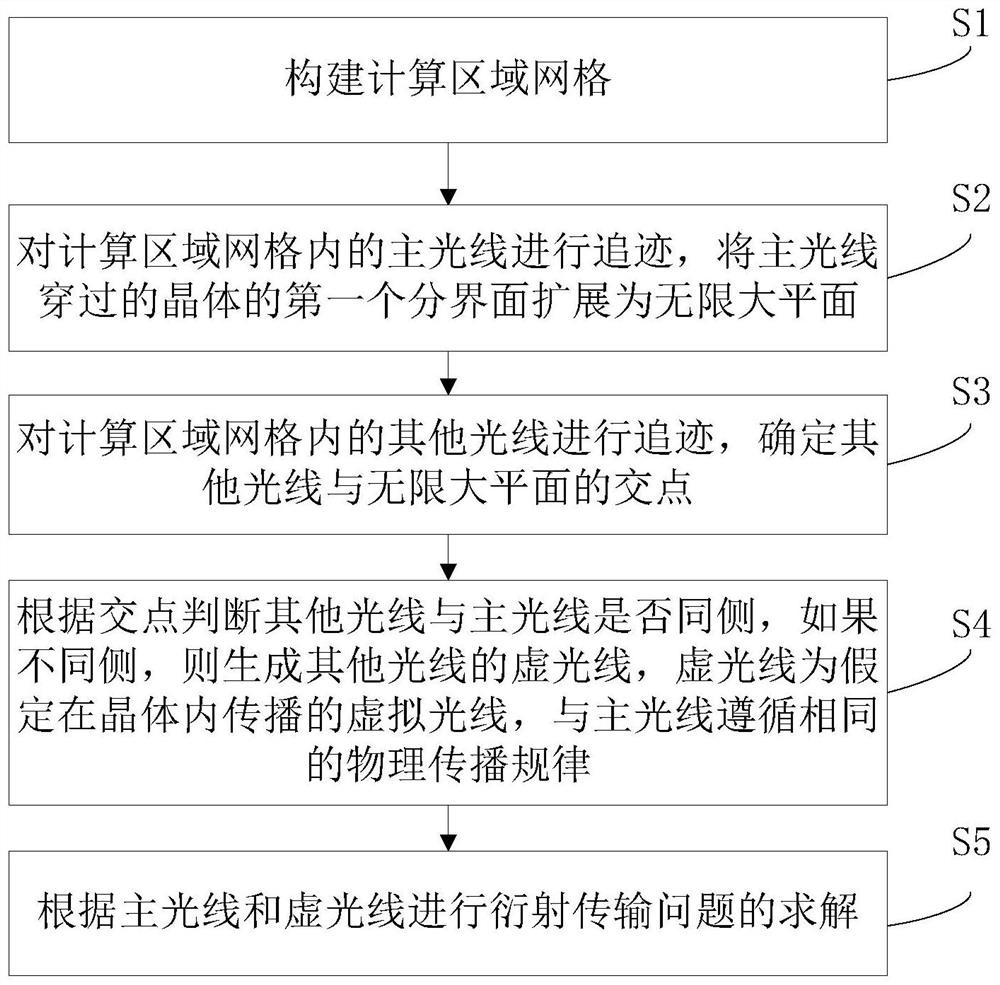

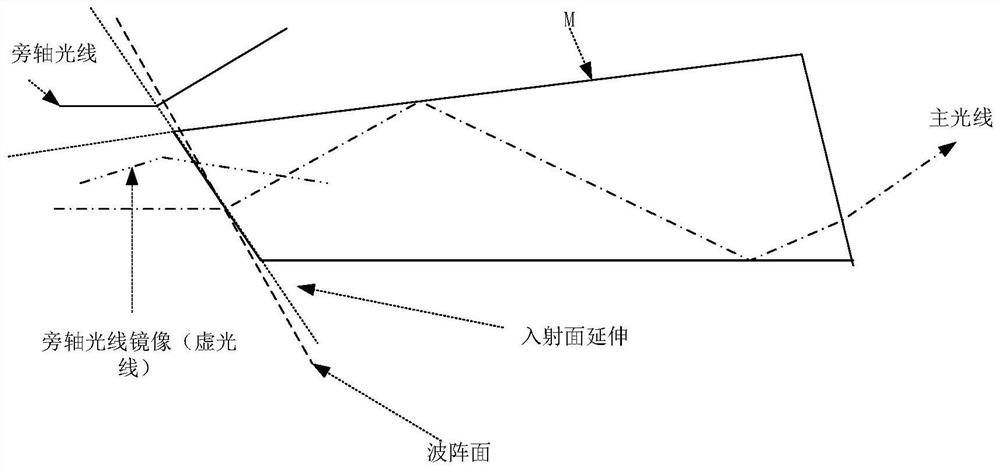

Solving method and system for light diffraction transmission problem

The invention discloses a solving method and system for a light diffraction transmission problem, and relates to the field of optics. The method comprises the steps of constructing a calculation region grid; tracing the main light in the calculation area grid, and expanding the first interface of the crystal through which the main light passes into an infinite plane; tracing other light in the calculation area grid, and determining intersection points of the other light and the infinite large plane; judging whether the other light and the main light are on the same side or not according to theintersection points, if not, generating virtual light of the other light, wherein the virtual light is supposed to be propagated in the crystal and follows the same physical propagation rule as the main light; and solving a diffraction transmission problem according to the main light and the virtual light. The method can be used for the diffraction transmission calculation process of plane reflection of any shape, has the advantage of high practicability, and solves the problem that a traditional light field diffraction transmission solving method cannot be applied to the propagation processof light in an unparallel plane.

Owner:INST OF APPLIED PHYSICS & COMPUTATIONAL MATHEMATICS +1

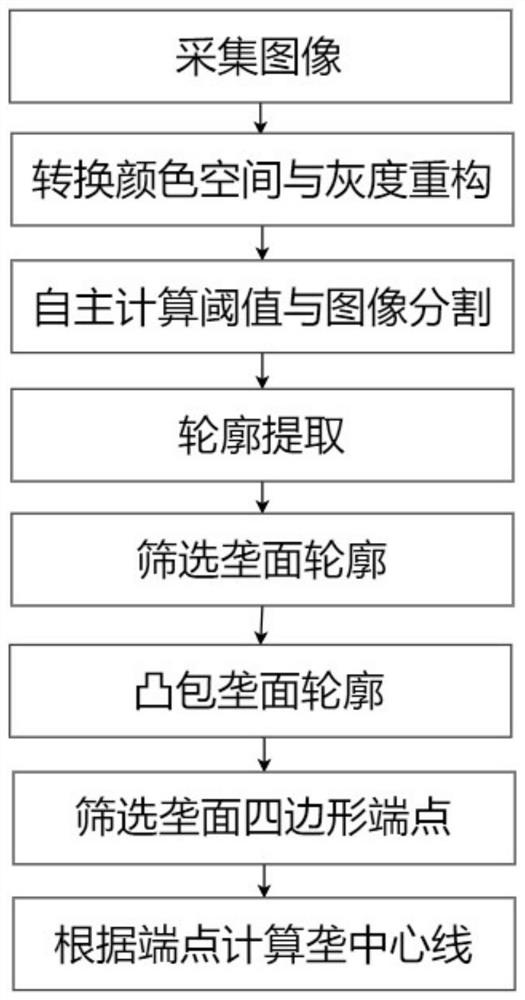

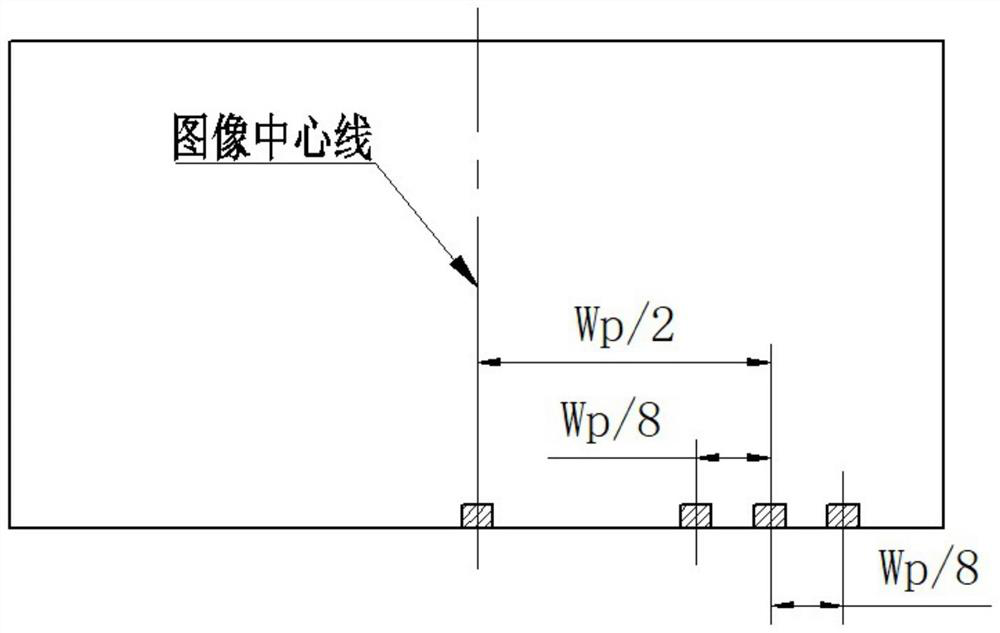

On-ridge operation machine navigation path identification method based on field ridge color features

PendingCN113963255AThe solution cannot be appliedEliminate the effects ofImage enhancementImage analysisGraph basedEnvironmental geology

Owner:JIANGSU UNIV

A Fault Diagnosis Method of Variable Speed/Variable Load Rolling Bearing Based on Mode Conversion

ActiveCN107884188BImplement fault diagnosisAccurate analysis and processingMachine part testingCharacter and pattern recognitionHigh energyEngineering

Owner:WENZHOU UNIV

Antibacterial antifogging agent and antibacterial long-acting antifogging wet wipe prepared by the same

ActiveCN113105868BReduce migration rateReduce churn rateBiocideOther chemical processesActive agentWet wipe

Owner:江苏南创化学与生命健康研究院有限公司 +2

A kind of polymer emulsion building waterproof paint and preparation method thereof

ActiveCN110527364BImprove performanceSolve the problem that low temperature cannot be constructedCoatingsEmulsionPlasticizer

Owner:芜湖东方雨虹建筑材料有限公司

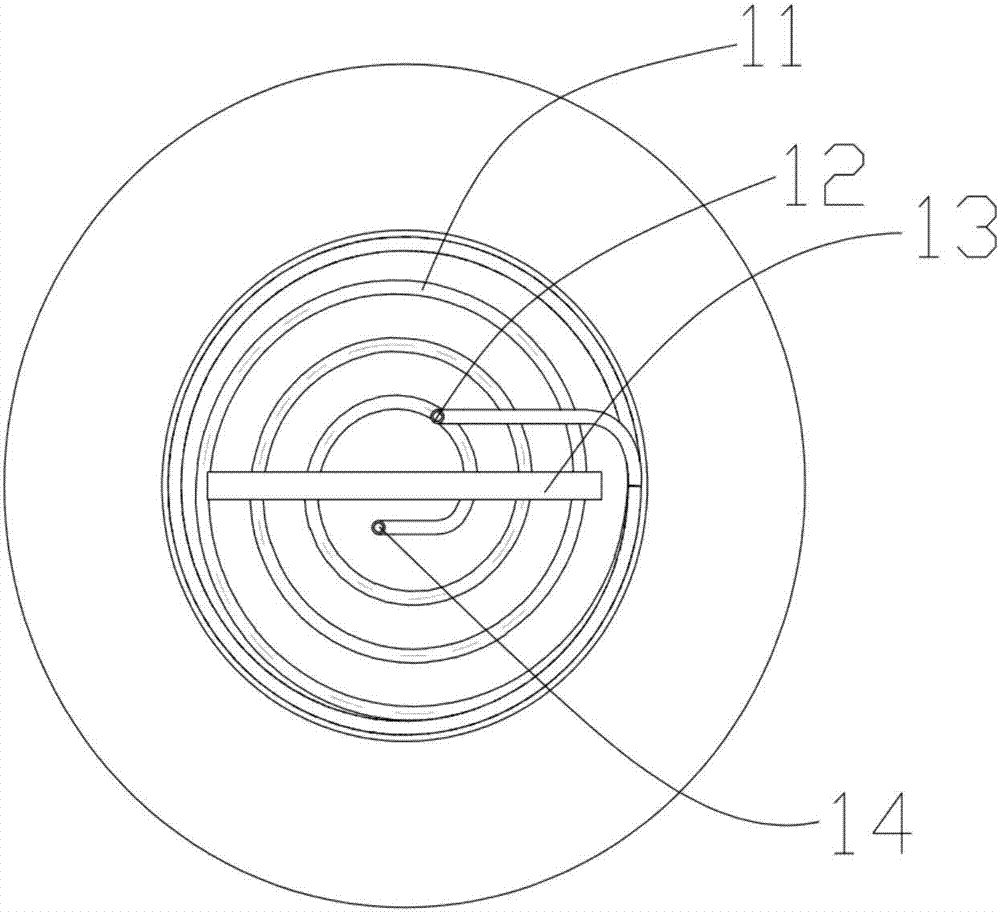

Novel electromagnetic smelting furnace

InactiveCN107036444AIncrease the heating areaReduce cooling areaCrucible furnacesSemi openEngineering

The invention discloses a novel electromagnetic melting furnace, which is characterized in that the melting furnace includes a heater and a furnace body, the heater is erected on the bottom boss of the molten pool formed by the furnace body, and the heater includes a coil , an insulation layer and a heating body, the insulation layer is attached to the inner wall of the heating body to form a semi-open insulation layer cavity, and the coil is spirally wound into a coil group with multiple turns, which is suitable for disposing in the insulation layer cavity. In the present invention, by placing the coil of the heater inside the heating body and using the outside of the heater as the heating surface, the heating area of the heater is increased, the heat dissipation area of the heater is reduced, the heat utilization rate of the furnace is improved, and resources are reduced. waste.

Owner:FOSHAN GAOJIE IND FURNACE CO LTD

Method and system for solving light diffraction transmission problems

ActiveCN111965837BThe solution cannot be appliedEasy to implementOptical elementsLight diffractionOptical field

The invention discloses a method and a system for solving the light diffraction transmission problem, and relates to the field of optics. The method includes: constructing a calculation area grid; tracing the chief ray in the calculation area grid, and expanding the first interface of the crystal through which the chief ray passes into an infinite plane; The rays are traced to determine the intersection of other rays and the infinite plane; according to the intersection, it is judged whether other rays are on the same side as the main ray, and if they are on different sides, the virtual rays of other rays are generated, and the virtual rays are assumed to propagate in the crystal. , which follows the same physical propagation law as the chief ray; the diffraction transmission problem is solved according to the chief ray and the virtual ray. The invention can be used for the diffraction transmission calculation process of plane reflection of any shape, has the advantage of strong practicability, and solves the problem that the traditional optical field diffraction transmission solution method cannot be applied in the process of light propagation in non-parallel planes.

Owner:INST OF APPLIED PHYSICS & COMPUTATIONAL MATHEMATICS +1

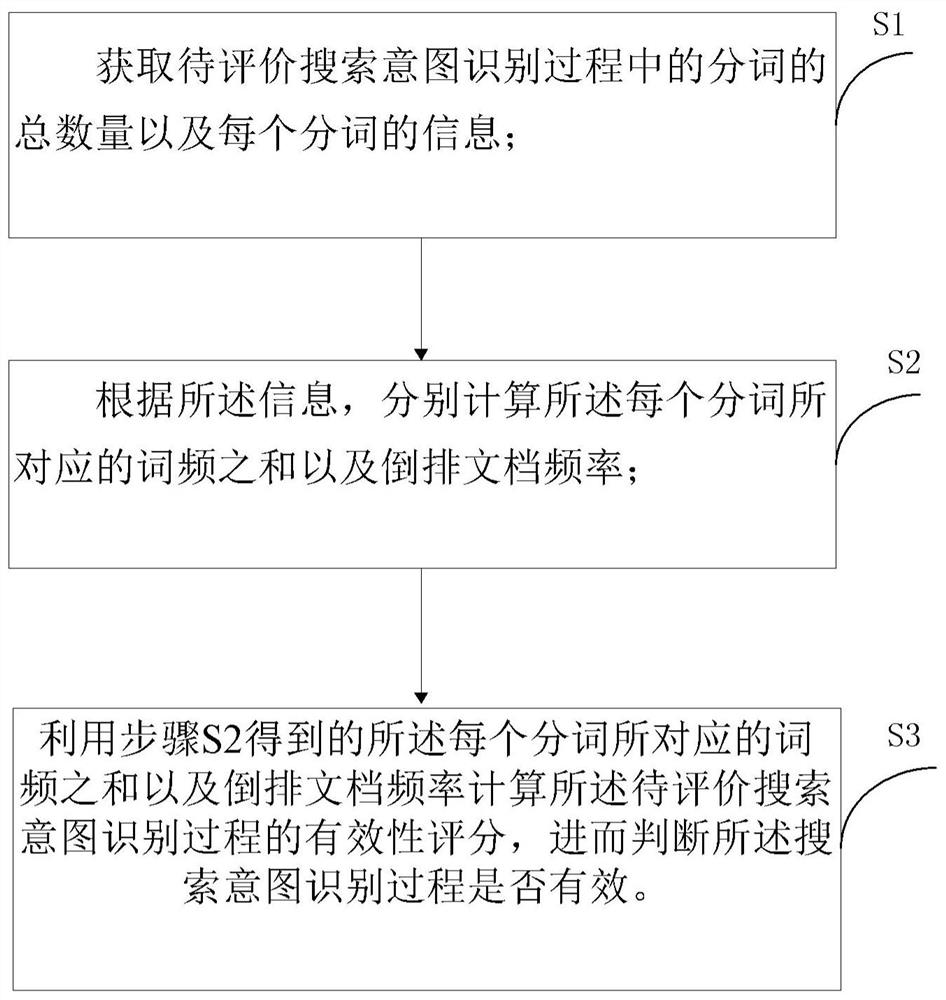

Evaluation method, storage medium and device for judging the effectiveness of search intent recognition

ActiveCN108415903BThe solution cannot be appliedDigital data information retrievalNatural language data processingPattern recognitionSearch intent

The present invention provides an evaluation method for judging the validity of search intent recognition, comprising the following steps: S1, obtaining the total number of word segmentations and information of each word segmentation in the search intent recognition process to be evaluated; S2, calculating separately according to the information The sum of the word frequencies corresponding to each word segment and the inverted document frequency; S3, using the sum of the word frequencies corresponding to each word segment obtained in step S2 and the inverted document frequency to calculate the search intent identification process to be evaluated. Effectiveness score, and then determine whether the search intent recognition process is effective. The present invention also relates to related computer-readable storage media and electronic devices.

Owner:WUHAN DOUYU NETWORK TECH CO LTD

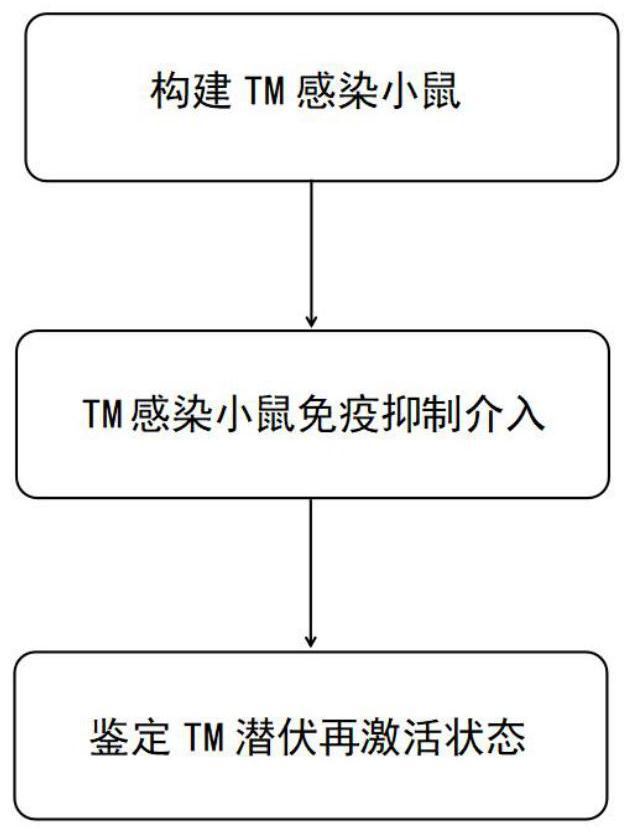

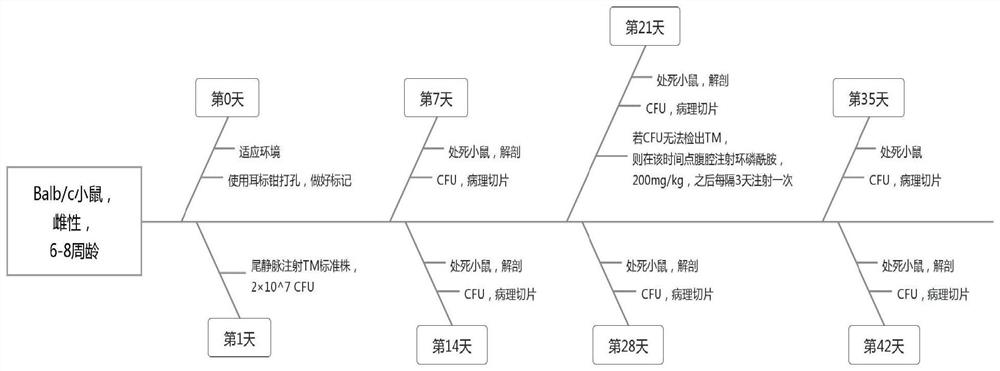

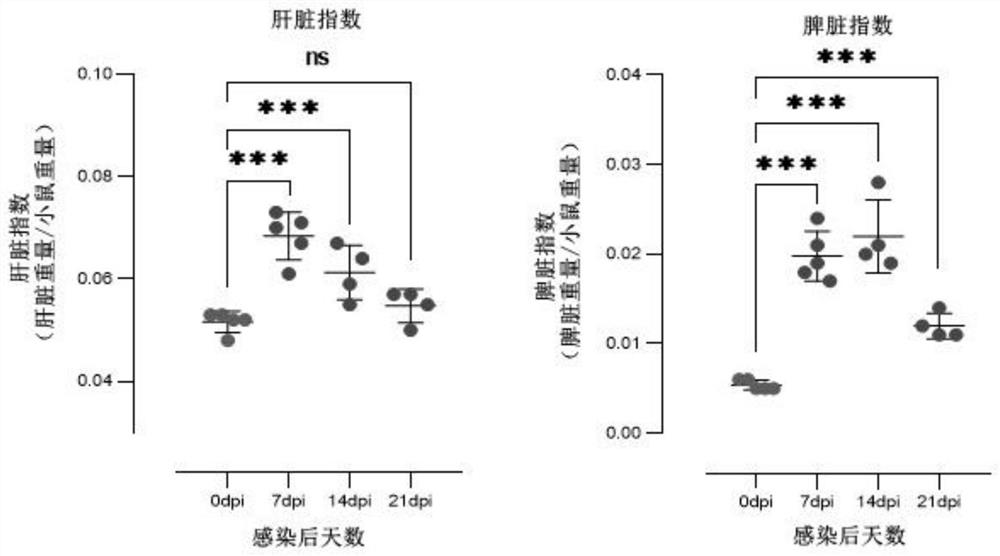

Construction method of mouse talaromyces marneffei latent reactivation model

PendingCN114651786ABroaden research ideasShort modeling cycleCompounds screening/testingAnimal husbandryImmunosuppressionBiomedical engineering

The invention relates to a construction method of a mouse talaromyces marneffei latent reactivation model, which comprises the following steps: constructing a TM infected mouse, performing immunosuppression intervention on the TM infected mouse, and finally detecting the TM latent reactivation state of the mouse to realize the construction of the model. The talaromyces marneffei latent reactivation model of the mouse is successfully established for the first time, and the TM latent reactivation model is established in the mouse body, so that the dynamic process of fungi in the human body is simulated, and a model basis is provided for researching the latent infection state of TM in the body. And the TM latent activation model is used as a tool model for researching the TM, so that the molecular mechanism of TM latent infection can be further clarified conveniently, a sufficient basis and an early-stage basis are provided for analyzing the pathogenesis of the TM, a tool basis is also provided for deeply excavating the TM latent infection mechanism, and the research and development of related drugs in the field are promoted.

Owner:GUANGXI MEDICAL UNIVERSITY

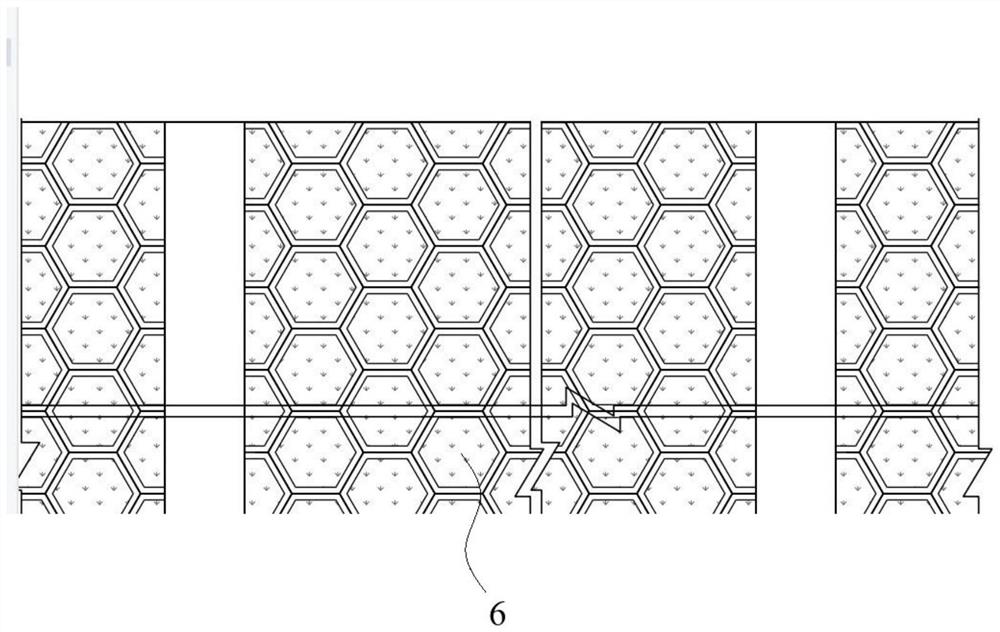

Three-dimensional rotary net-shaped contact body assembly mounting structure

InactiveCN110615529AThe solution cannot be appliedLess land acquisitionTreatment with aerobic and anaerobic processesSustainable biological treatmentWater qualityEngineering

The invention discloses a three-dimensional rotary type net-shaped contact body assembly mounting structure, and relates to the technical field of environmental protection equipment. A three-dimensional rotary type net-shaped contact body assembly is directly installed on a tank body, the occupied area does not need to be increased, an equipment room does not need to be built, and various pipelines, valves and air supply devices are not needed. Less land is occupied when sewage treatment plants with the same scale are newly built, and early-stage investment is greatly reduced. According to different scales of sewage treatment plants and different inlet water qualities, the number of the required three-dimensional rotary net-shaped contact body assemblies is different, and corresponding design can be carried out according to the installation number and the occupied area. The problem that an existing three-dimensional net-shaped rotating body device cannot be applied to a newly-built sewage treatment plant with the limited land area is solved, and the cost is greatly reduced.

Owner:青海洁神环境科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com