Application of deep learning in product appearance defect detection

A technology of deep learning and defect detection, applied in the direction of optical test defects/defects, neural learning methods, measuring devices, etc. The waste of human resources, the effect of improving detection speed and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

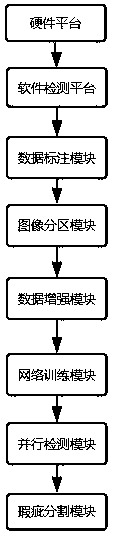

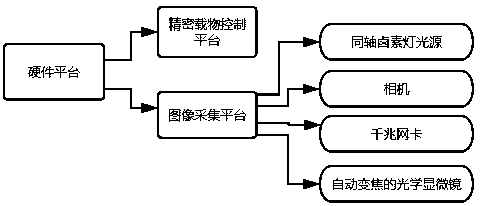

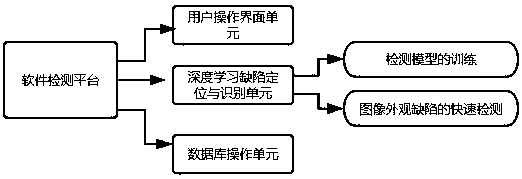

[0035] The application of deep learning in the detection of product appearance defects, such as Figure 1-3 As shown, it includes hardware platform, software detection platform, data labeling module, image partition module, data enhancement module, network training module, parallel detection module and defect segmentation module. The hardware platform includes precision loading control platform and image acquisition platform; data labeling The module is used to mark the type, position and pixel of the defect; the image partition module is used to divide the large image into small images; the data enhancement module is used to realize the expansion of the data set; the parallel detection module adopts multi-threading mode, which can choose to process the same The accuracy of each image is improved, and different images can be processed to achieve detection acceleration; the blemish segmentation module is used to obtain the specific shape of the blemish.

[0036] The precision l...

Embodiment 2

[0053] The application of deep learning in the detection of product appearance defects, such as Figure 1-3 As shown, it includes hardware platform, software detection platform, data labeling module, data enhancement module, parallel detection module and defect segmentation module. The hardware platform includes precision loading control platform and image acquisition platform; the data labeling module is used to mark the defect type, location and pixels; the image partition module is used to divide a large image into small images; the data enhancement module is used to realize the expansion of the data set; Different images can be processed to achieve detection acceleration; the blemish segmentation module is used to obtain the specific shape of the blemish.

[0054] The precision loading control platform includes a stage, which adopts a vacuum adsorption stage device, so that the detected flexible substrate is firmly attached to the stage; the motor and the driving device ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com