High-density flexible substrate appearance defect detection system and method based on depth learning

A deep learning and appearance defect technology, applied in optical testing defects/defects, measuring devices, scientific instruments, etc., can solve the problems of low efficiency of systems and methods, inability to detect multiple defects at the same time, avoid waste and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

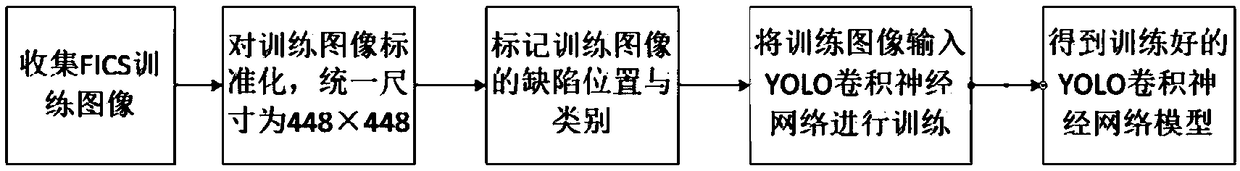

[0033] In order to describe the present invention more specifically, the flexible substrate appearance defect detection system and method will be described in detail below in conjunction with the accompanying drawings and specific embodiments. network), all of which can be understood or implemented by those skilled in the art with reference to the prior art, and will not be repeated here.

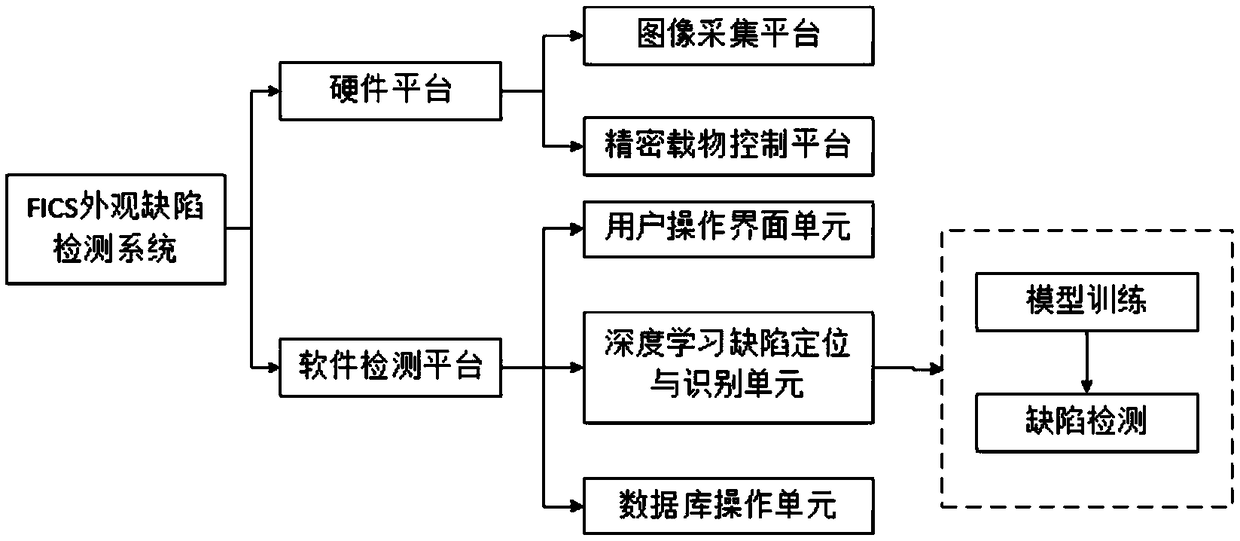

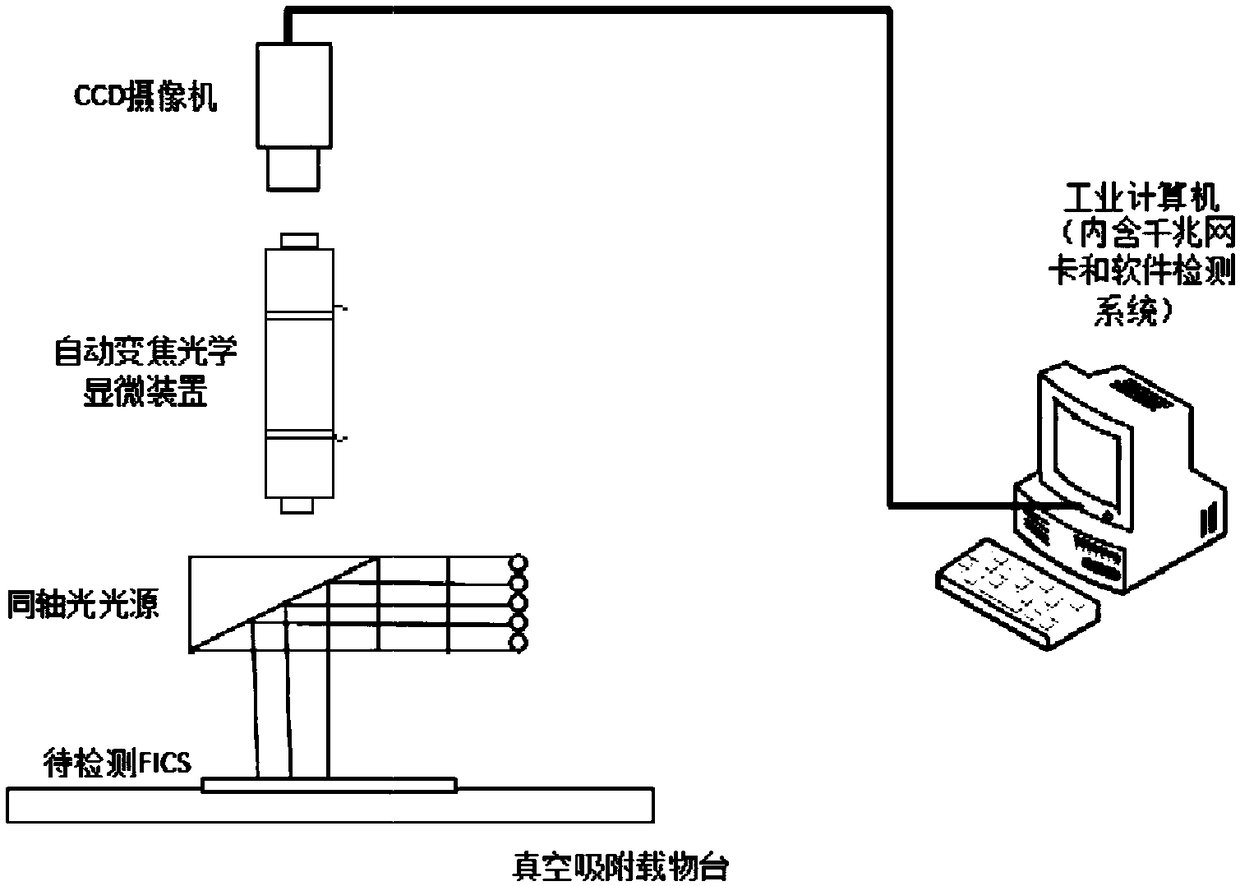

[0034] Such as figure 1 As shown, a high-density flexible substrate appearance defect detection system based on deep learning includes a hardware platform and a software detection platform. The hardware platform consists of two parts. The first part is the precision loading control platform, which consists of the following three parts: ⑴The stage adopts a vacuum adsorption stage device, so that the flexible substrate to be tested is firmly attached to the stage , ⑵ motor and driving device, used to drive the movement of the stage, ⑶ motion control board, used to transmit the control signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com