Original version concrete bracket system construction method

A construction method, the technology of concrete bucket arch, applied in the direction of roof, roof, building components, etc., can solve the problems of construction speed and construction quality decline, construction cost increase, wood loss, etc., to improve production efficiency and product quality, and improve construction efficiency and quality, and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

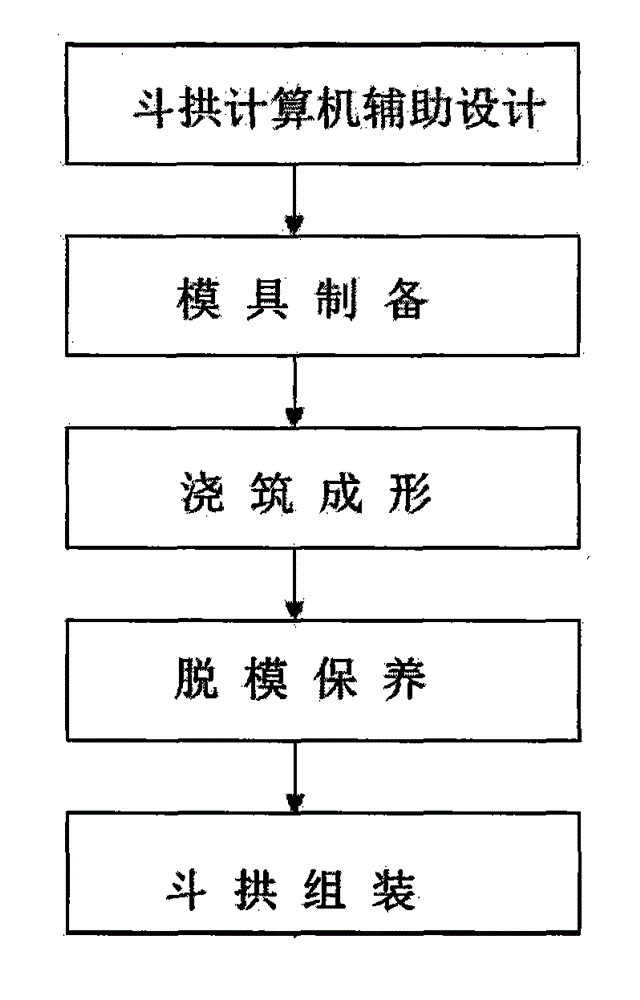

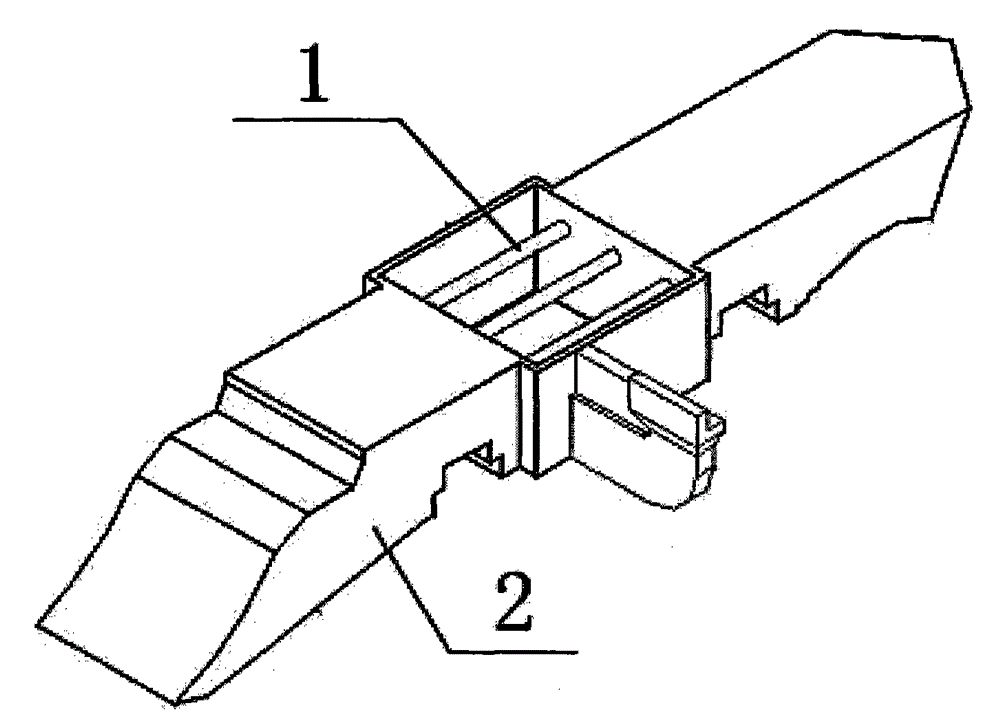

[0020] Such as figure 1 and 2 An original version of the concrete bucket arch construction method shown, the construction method includes the following steps:

[0021] The first step is the computer-aided design of the bucket arch. According to the requirements of the building construction, use the computer-aided design software to draw the structural drawings of the small bucket, the Zhengshenke bucket arch, the Jiaoke bucket arch and the column head bucket arch, as well as the auxiliary accessories of various types of bucket arches and production. Mold drawings;

[0022] The second step is mold preparation. According to the drawn drawings, special molds for Zhengshen Ke Dou Gong, Jiao Ke Dou Gong and Column Head Ke Dou Gong are prepared respectively;

[0023] The third step is pouring and forming. According to the drawn drawings, firstly use steel bars to prepare the structural bars 1 of the Zhengshen Ke Dou Gong, Jiao Ke Dou Arch and Column Head Ke Dou Gong respectively, ...

Embodiment 2

[0029] Such as figure 1 and 2 An original version of the concrete bucket arch construction method shown, the construction method includes the following steps:

[0030] The first step is the computer-aided design of the bucket arch. According to the requirements of the building construction, use the computer-aided design software to draw the structural drawings of the small bucket, the Zhengshenke bucket arch, the Jiaoke bucket arch and the column head bucket arch, as well as the auxiliary accessories of various types of bucket arches and production. Mold drawings;

[0031] The second step is mold preparation. According to the drawn drawings, special molds for Zhengshen Ke Dou Gong, Jiao Ke Dou Gong and Column Head Ke Dou Gong are prepared respectively;

[0032] The third step is pouring and forming. According to the drawn drawings, firstly use steel bars to prepare the structural bars 1 of the Zhengshen Ke Dou Gong, Jiao Ke Dou Arch and Column Head Ke Dou Arch. Carry out po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com