Method and device for cooperative flue gas desulfurization and sewage organic matter degradation and denitrification

A technology of organic matter and flue gas, applied in the field of pollution control, can solve the problems of large excess sludge output, etc., and achieve the effects of large output, efficient desulfurization, and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Example 1 A device for purifying sewage with flue gas desulfurization waste liquid

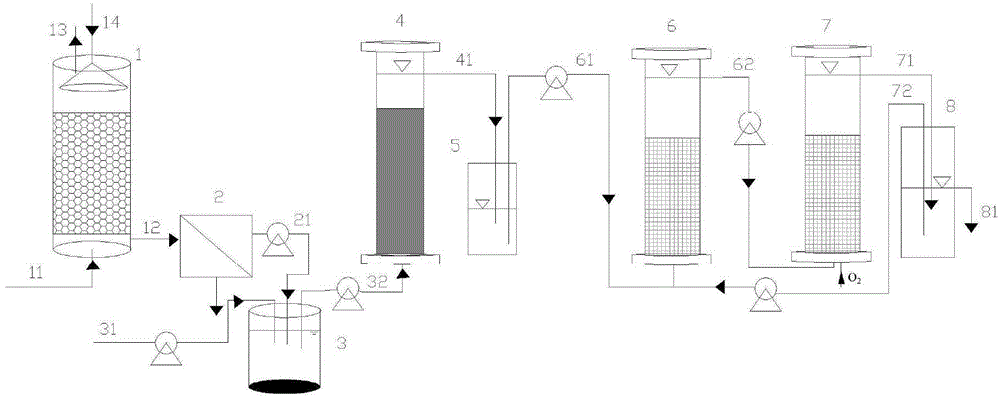

[0082] Such as figure 1 As shown, the present invention provides a kind of device that purifies sewage with flue gas desulfurization waste liquid, and this device comprises flue gas dedusting desulfurization spray tower 1, mixing pool 3, sulfite reduction reactor 4, denitrification reactor 6 and A nitrification reactor 7, the flue gas dedusting and desulfurization spray tower 1, a mixing tank 3, a sulfite reduction reactor 4, a denitrification reactor 6 and a nitrification reactor are connected in sequence through a main water inlet pipeline through 7, and the reaction Between the nitrification reactor 6 and the nitrification reactor 7 there are return pipelines 71 and 72 which can return the effluent from the nitrification reactor 7 to the denitrification reactor 6;

[0083] A sedimentation tank 2 is provided between the flue gas dedusting and desulfurization spray tower 1 and the m...

Embodiment 2

[0092] Embodiment 2 A method of purifying sewage with flue gas desulfurization waste liquid

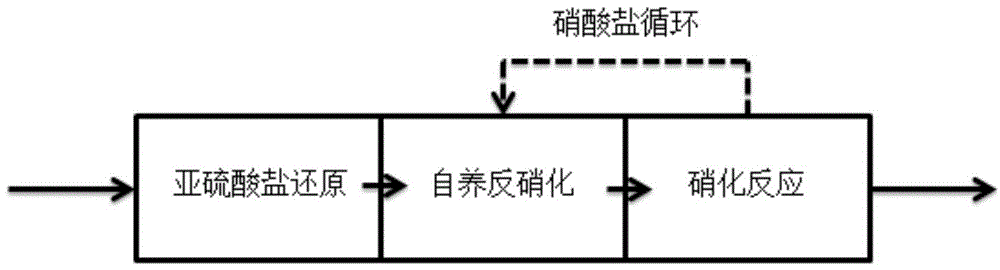

[0093] combine figure 1 (Schematic diagram of flue gas dedusting, desulfurization and sewage treatment equipment) and figure 2 (Schematic diagram of the flow of the sewage purification treatment method) The sewage treatment process is explained as follows.

[0094] 1. Pretreatment before operation of the sewage purification device with flue gas desulfurization waste liquid

[0095] (1) Sludge inoculation and acclimatization of sulfite acid reduction reactor 4

[0096] The sludge of sulfite reduction reactor 1 is taken from the secondary settling tank of Tung Chung Sewage Treatment Plant in Hong Kong (as long as it is activated sludge containing sulfate reducing bacteria), and is mixed with flue gas desulfurization waste liquid and domestic sewage As the influent of the reactor, the sludge in the reactor is domesticated and cultivated, and the dissolved oxygen concentration is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com