Device for heat exchange of electrolytic bath

A technology of electrolytic cells and heat exchangers, which is applied in the direction of electrolytic process and electrolytic components, etc. It can solve the problems of electrolytic cell heat balance damage, current efficiency reduction, equipment deformation, etc., shorten heat exchange time, reduce mass balance, and ensure safe implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples illustrate this patent in detail.

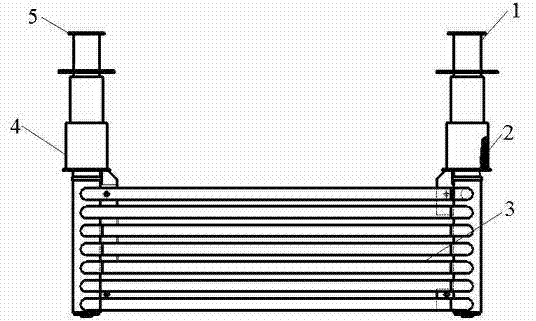

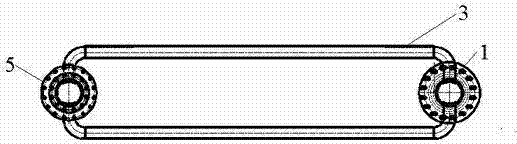

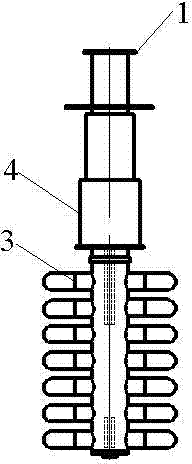

[0029] Such as Figure 1~Figure 3 Shown: a device for heat exchange in an electrolytic cell of the present invention includes an air inlet pipe 1, a pouring material 2, a cooling coil pipe 3, a stainless steel sleeve 4, and an air outlet pipe 5.

[0030] Such as Figure 4~Figure 5 It is a schematic diagram of the external fan and duct installation elevation and top view. Its structure is: electrolytic cell 6, air duct 7, and fan 8. The wind speed of the fan is 70m 3 , The motor power is 18kw blower, the fan is fixed on the ground near the electrolytic cell, and is effectively insulated; the air duct is composed of straight pipes, elbows and connecting flanges made of DN250 and Q235 materials. The fan is flanged to the air inlet of the heat exchanger 1 on the cover of the electrolytic cell through a wind pipe. The heat exchange device adjusts the temperature in the 6 cells of the electrolyzer to ensure the normal wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com