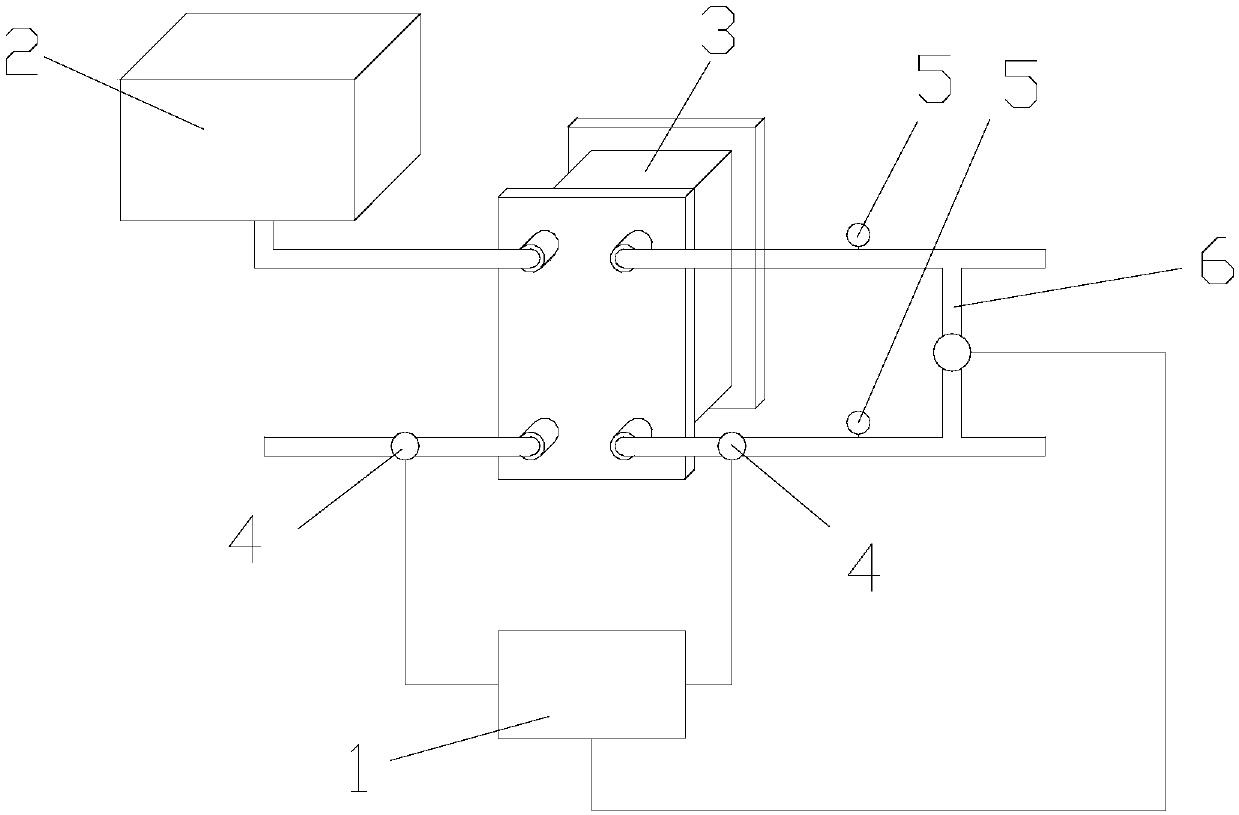

Flue gas waste heat recovery and heat exchange system

A heat exchange system and flue gas waste heat technology, applied in indirect heat exchangers, heat exchanger types, climate sustainability, etc., can solve the problems of low energy efficiency ratio of flue gas heat energy recovery, achieve simple measurement and ensure detection accuracy , the effect of high automation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

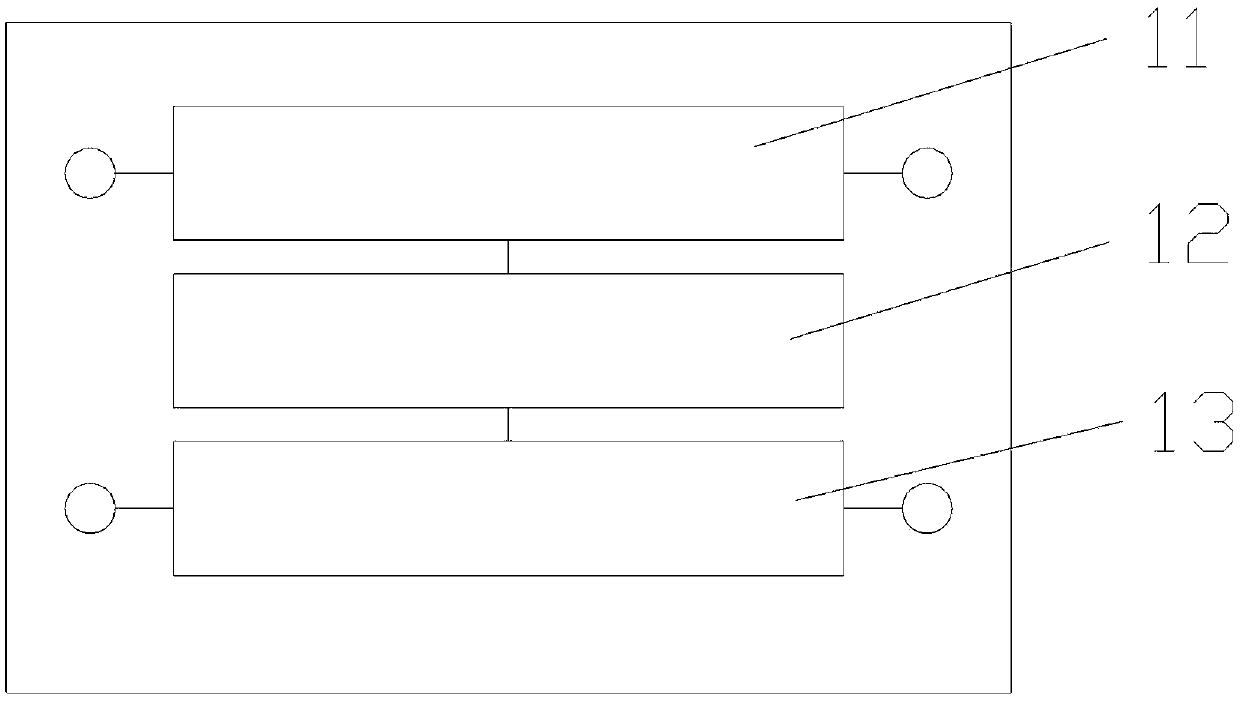

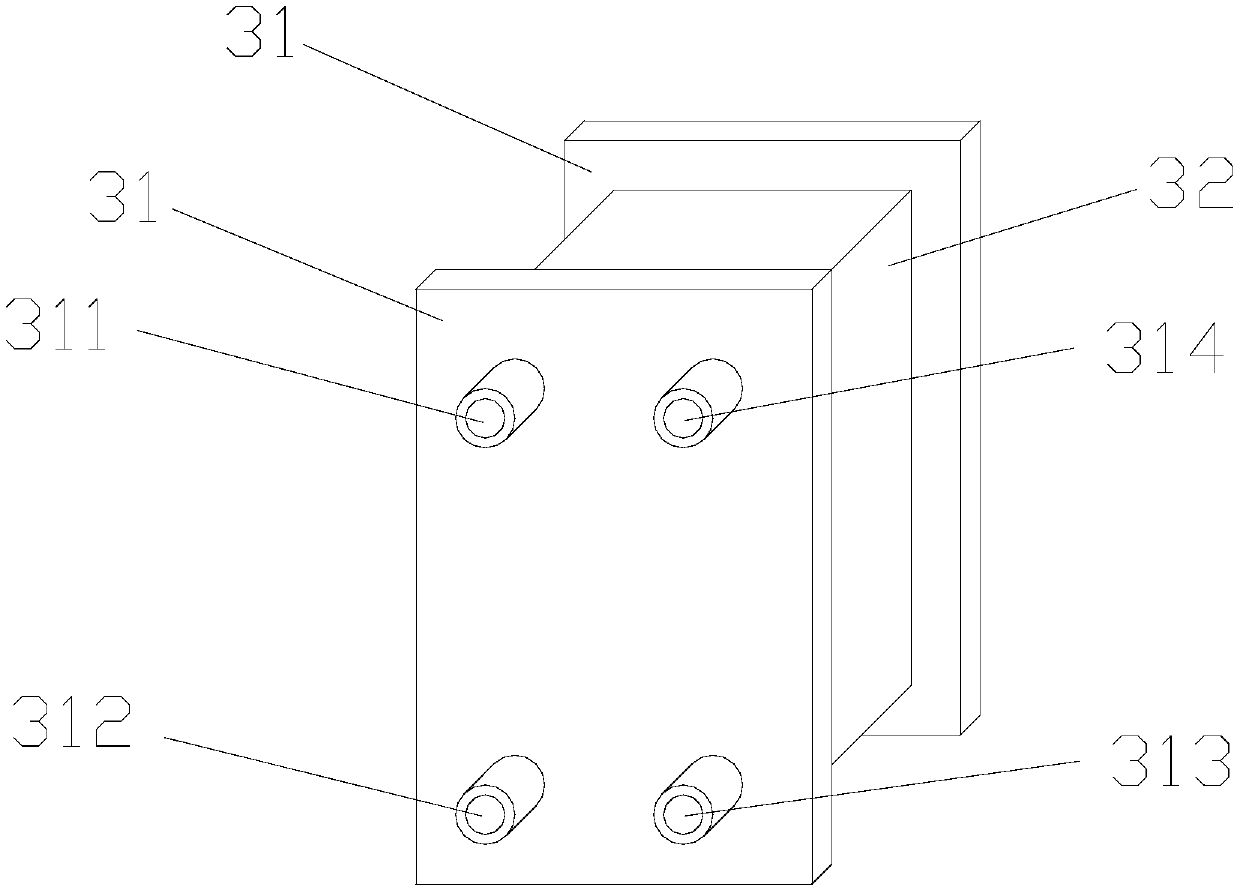

Method used

Image

Examples

Embodiment 1

[0056] In this example, the above-mentioned system will be used to exchange heat for the flue gas, in which 100 tons of flue gas is used for heat exchange, the exhaust gas temperature is 90°C, the heat exchange is 35°C, the heat exchange temperature difference is 90-35=55°C, and the flue gas quality is 1.256 kg / m 3 , 100 boilers discharge 200,000-250,000 m of flue gas per hour 3 / h, this embodiment takes an average of 225,000 m 3 / h calculation; circulation pump flow:

[0057] Q=cm(t2-t1)

[0058] 1398870 joules=4.2*1000*m*55

[0059] m=1398870 joules / 4.2*1000*5

[0060] =66.6*24=1598*2 safety factor=3196t

[0061] Circulation pump flow: 3196 / 24=133 tons.

[0062] Calculate according to Q=cm(t2-t1), where Q is the total heat of the flue gas; C is the specific heat capacity of the flue gas, and the specific heat capacity of the flue gas at 100°C is C=1; m is the mass of the flue gas; t2 is the inlet temperature of the flue gas; t1 is the flue gas discharge temperature. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com