Diesel engine pollutant treatment system and method

A pollutant treatment and diesel engine technology, applied in the field of diesel engine pollutant treatment system, can solve problems such as difficult CDPF work, uncertainty, CDPF regeneration efficiency decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

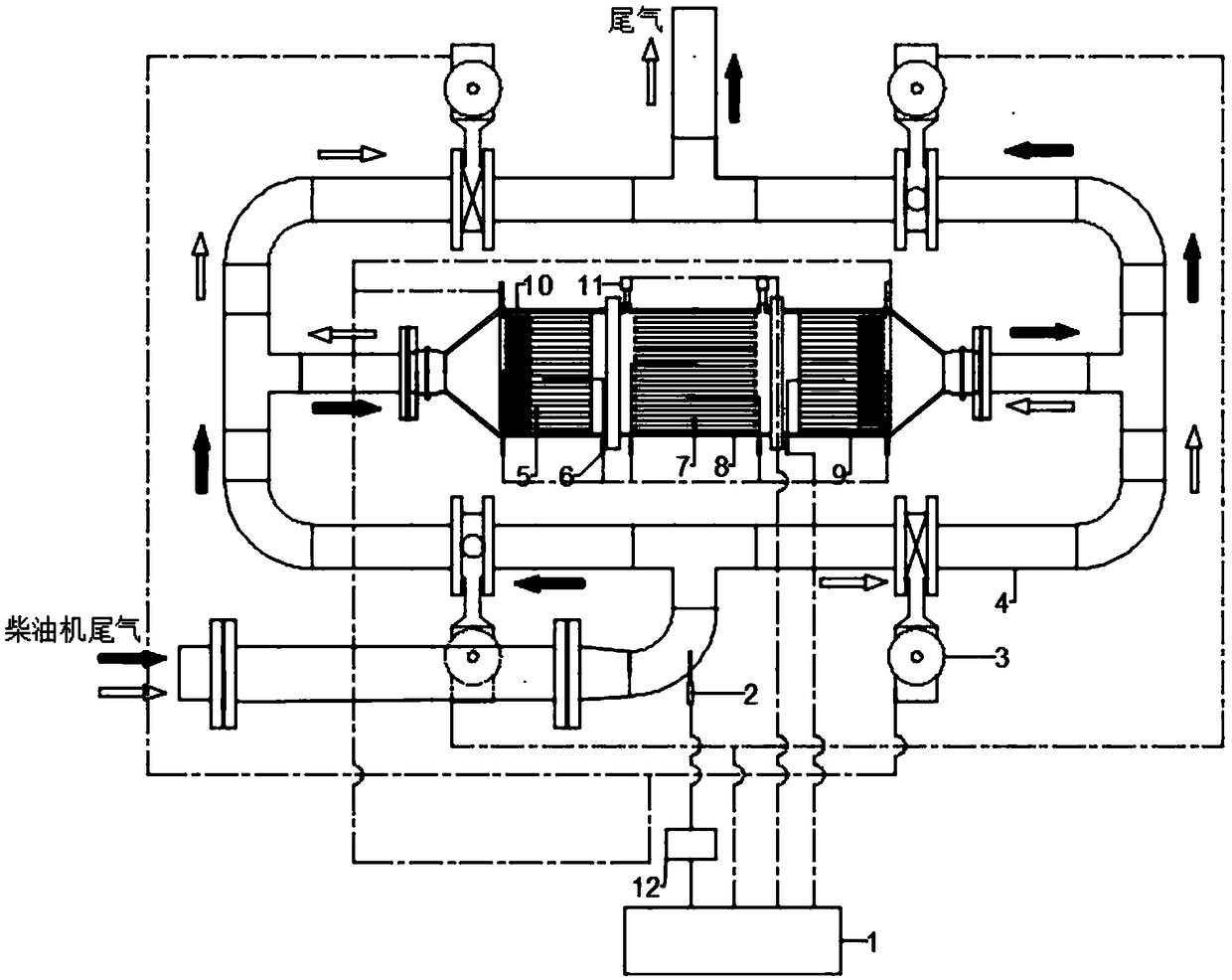

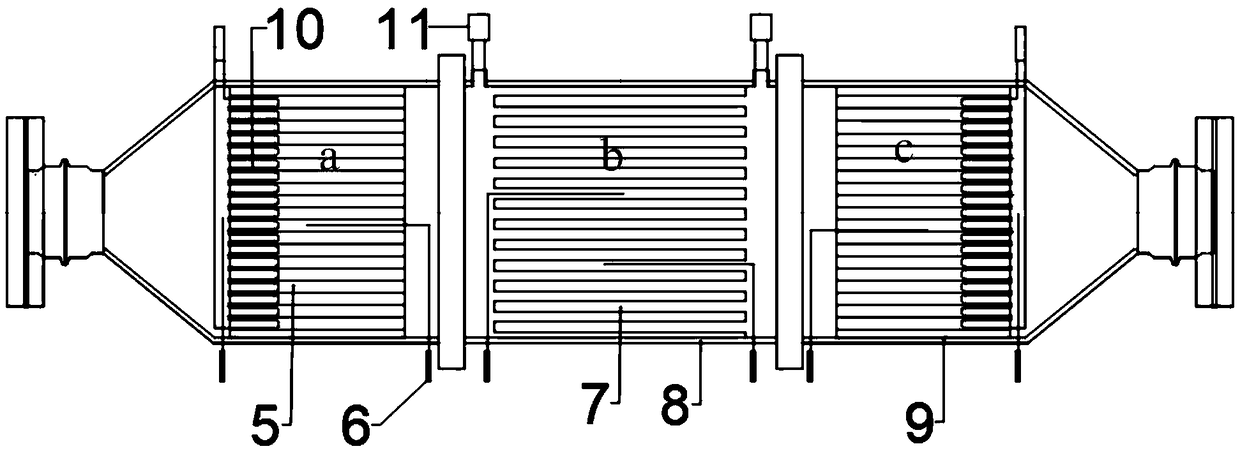

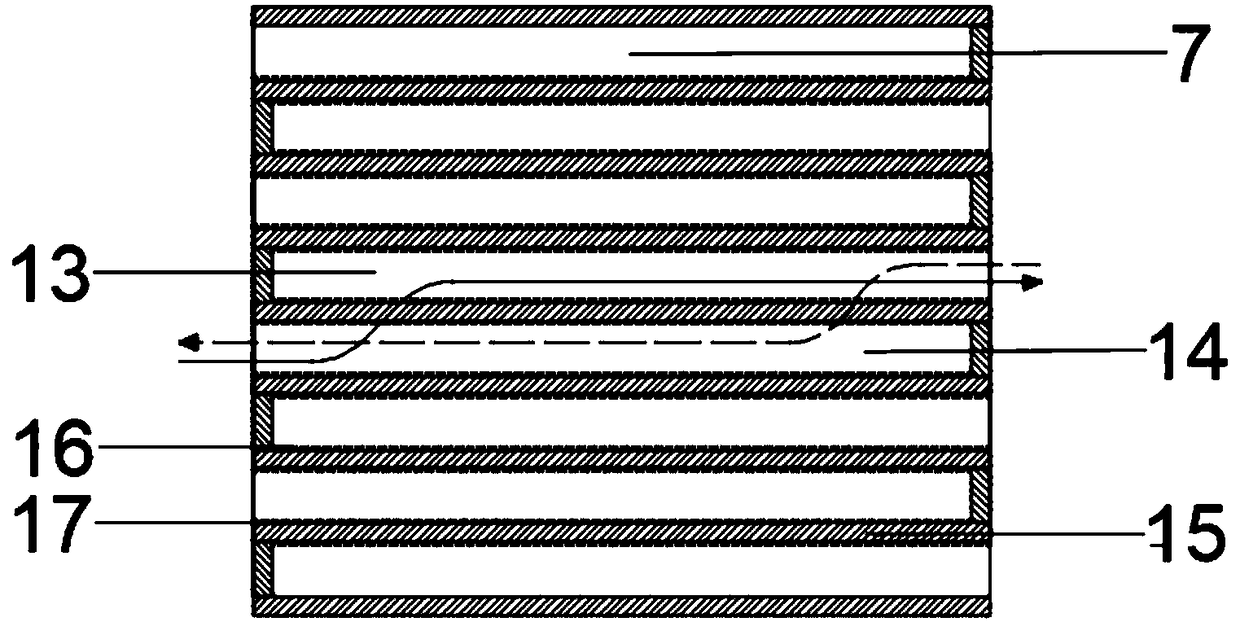

[0045] Such as figure 1 As shown, the diesel engine pollutant treatment system includes a control system 1, a catalytic particulate filter CDPF b, an oxidation catalytic converter DOC and a periodic reversing pipeline 4, wherein: the two ends of the catalytic particulate filter CDPF b are respectively The first oxidation catalyst DOC a and the second oxidation catalyst DOC c are connected, and the respective free ends of the first oxidation catalyst DOC a and the second oxidation catalyst DOC c communicate with the cycle reversing pipeline 4; the cycle The reversing pipeline 4 is connected with the first oxidation catalytic converter DOC a and the second oxidation catalytic converter DOC c to form a closed circulation pipeline. Two pairs of electromagnetic valves 3 that are synchronously opened and closed respectively are arranged on the closed circulation pipeline, and are connected with the outside world. Connected exhaust gas inlet and exhaust gas outlet, two pairs of solen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole density | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com