Adsorbing condensing type oil vapor recovery device for effectively preventing adsorption temperature rise and oil vapor recovery method

A recovery device and condensing technology, applied in the field of adsorption condensation oil and gas recovery devices, can solve problems such as increasing energy consumption, increasing investment, and increasing system complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

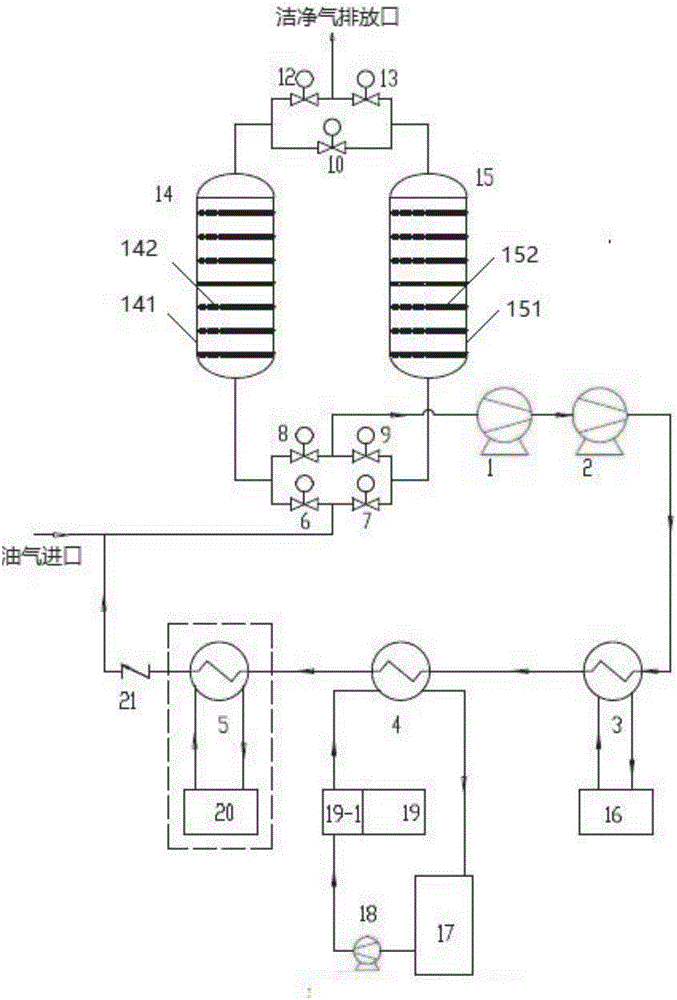

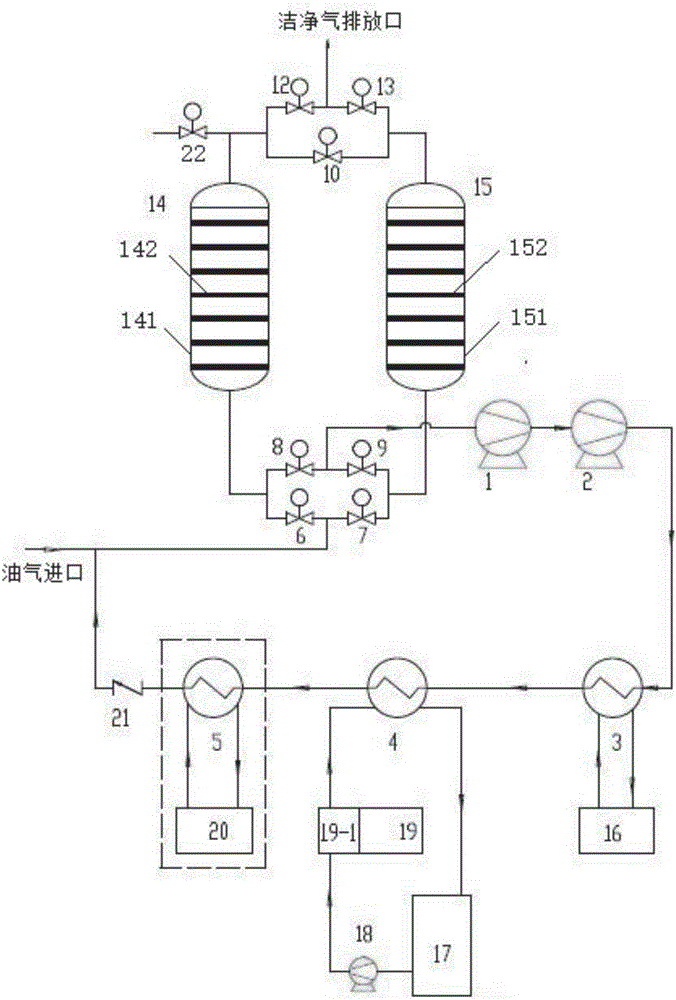

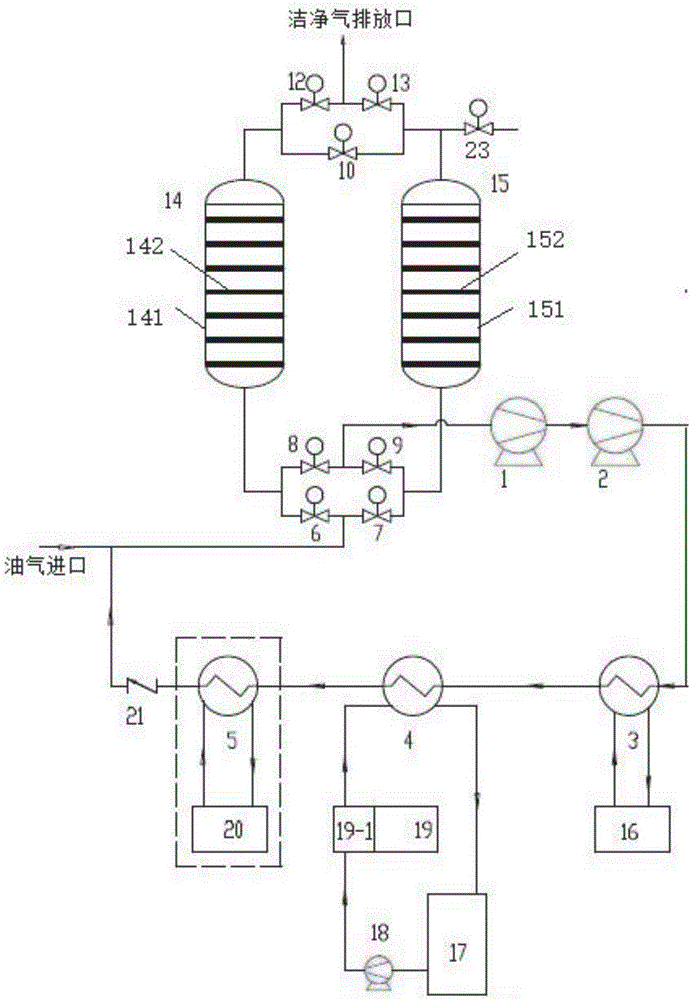

[0131] Such as Figure 1-5 As shown, the present invention discloses an adsorption condensation type oil gas recovery device that can effectively prevent adsorption temperature rise, including oil gas inlet, first valve group, adsorption tank group, second valve group, clean gas discharge port, vacuum pump group, first stage Oil-gas condenser 3, secondary oil-gas condenser 4, tertiary oil-gas condenser 5 and check valve 21, wherein:

[0132] The first valve group is composed of an intake valve group and a vacuum valve group connected in parallel below the adsorption tank group;

[0133] The second valve group is composed of an exhaust valve group located above the adsorption tank group and a purge valve group connected in parallel;

[0134] The purge valve group, the adsorption tank group, the vacuum valve group, the vacuum pump group, the first-stage oil-gas condenser 3, the second-stage oil-gas condenser 4, the third-stage oil-gas condenser 5 and the check valve 21 are conn...

Embodiment 2

[0165] Such as Figure 9 As shown, the present invention also discloses an adsorption condensation oil gas recovery method that effectively prevents the temperature rise of adsorption, comprising the following steps:

[0166] Step 1: The oil and gas to be treated enter through the oil and gas inlet, mix with a very small amount of uncondensed oil and gas discharged from the oil and gas condensing system (first-stage oil-gas condenser 3, second-stage oil-gas condenser 4 and third-stage oil-gas condenser 5), and then pass through the inlet The gas valve group enters the corresponding activated carbon adsorption tank, and the oil gas enters the left adsorption tank 14 through the left oil and gas inlet valve 6, and is adsorbed and intercepted by the first adsorbent in the left adsorption tank 14, and the solid-liquid phase change material absorbs a large amount of adsorption heat through the finned tube The solid-liquid phase change material is changed from solid to liquid, and t...

Embodiment 3

[0170] Such as Figure 10 As shown, the present invention additionally discloses an adsorption condensation oil gas recovery method that effectively prevents the temperature rise of adsorption, and is characterized in that it comprises the following steps:

[0171] Step A: The oil and gas to be treated enter through the oil and gas inlet, mix with a very small amount of uncondensed oil and gas discharged from the oil and gas condensing system (first-stage oil-gas condenser 3, second-stage oil-gas condenser 4 and third-stage oil-gas condenser 5), and then pass through the inlet The gas valve group enters the corresponding activated carbon adsorption tank, and the oil gas enters the right adsorption tank 15 through the right oil and gas inlet valve 7, and is adsorbed and intercepted by the second adsorbent in the right adsorption tank 15, and the solid-liquid phase change material absorbs a large amount of adsorption heat through the finned tube The solid-liquid phase change mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat of phase change | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com