Method for preparing gypsum by removing boiler flue gas sulphur dioxide with white slime from ammonia alkali factory

A technology of sulfur dioxide and boiler flue gas, applied in the direction of calcium/strontium/barium sulfate, etc., can solve the problems such as the useless value of calcium sulfite, complicated preparation process of desulfurizer, and many equipment, etc., to achieve broad commercial utilization prospects and achieve clean The effect of low production and investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

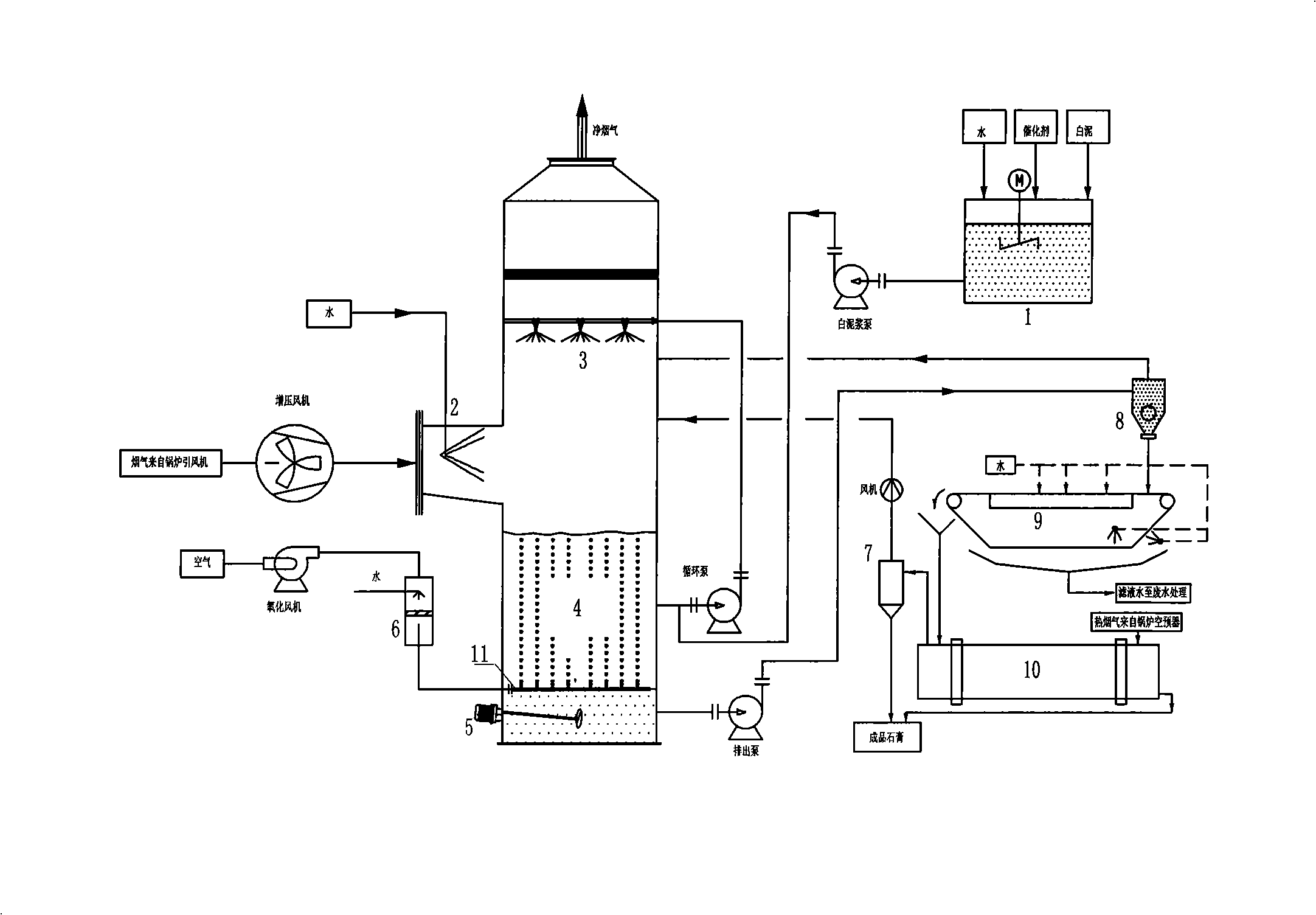

Method used

Image

Examples

Embodiment 1

[0048] Three 65t / h coal-fired boilers in an alkali plant, the sulfur content of the coal is 1.2%, and the flue gas volume is 3×85000Nm 3 / h, the sulfur dioxide content is 2160mg / Nm 3 , The white mud composition of the alkali plant is shown in Table 1:

[0049] Table 1 White mud composition analysis table

[0050] CaO

MgO

SiO 2

Al 2 O 3

Fe 2 O 3

Na 2 O

K 2 O

P 2 O 5

Cl -

S

Loss

40.18

3.56

2.75

1.98

0.63

1.04

0.057

0.080

3.50

4.18

37.13

[0051] Note: In the table, the calcium carbonate in the white mud is all converted to calcium oxide.

[0052] The dust-removed flue gas discharged from the three boilers is sent to a spray tower by a booster fan. The inlet flue gas temperature is 130℃, and the flue gas flow rate in the spray tower is controlled at 3.5-3.8m / s. Use this alkali plant The white mud is prepared into a white mud slurry with a water co...

Embodiment 2

[0056] Two 410t / h coal-fired boilers in a coal-fired power plant, the sulfur content of the coal is 1.5%, and the flue gas volume is 2×55000Nm 3 / h, the sulfur dioxide content is 2860mg / Nm 3 . The dust-removed flue gas discharged from each boiler is sent to two spray towers through two booster fans. The inlet flue gas temperature is 145℃, the flue gas flow rate in the spray tower is controlled at 3.8m / s, and the water content is The white mud slurry with a concentration of 80% is pumped into the absorption zone of the spray tower, and is sprayed in the spray zone cyclically, and contacts and reacts with the flue gas, and the sulfur dioxide in the flue gas is removed. The liquid-gas ratio of the spray tower is 12l / Nm 3 , Control the pH value of the oxidation crystallization pool to 5.8. After desulfurization, the flue gas is discharged from the chimney after the mist eliminator on the upper part of the spray tower. The desulfurization liquid after contact with the flue gas is oxidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com