Methods and compositions for improving the surface properties of fabrics, garments, textiles and other substrates

a technology of textiles and surface properties, applied in the preparation of detergent mixtures, liquid repellent fibres, detergent compounding agents, etc., can solve the problems of fading of colors, loss of surface smoothness, and fading of native unprotected fibers, so as to improve optical properties, reduce odor, and improve wearability. , the effect of improving the surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

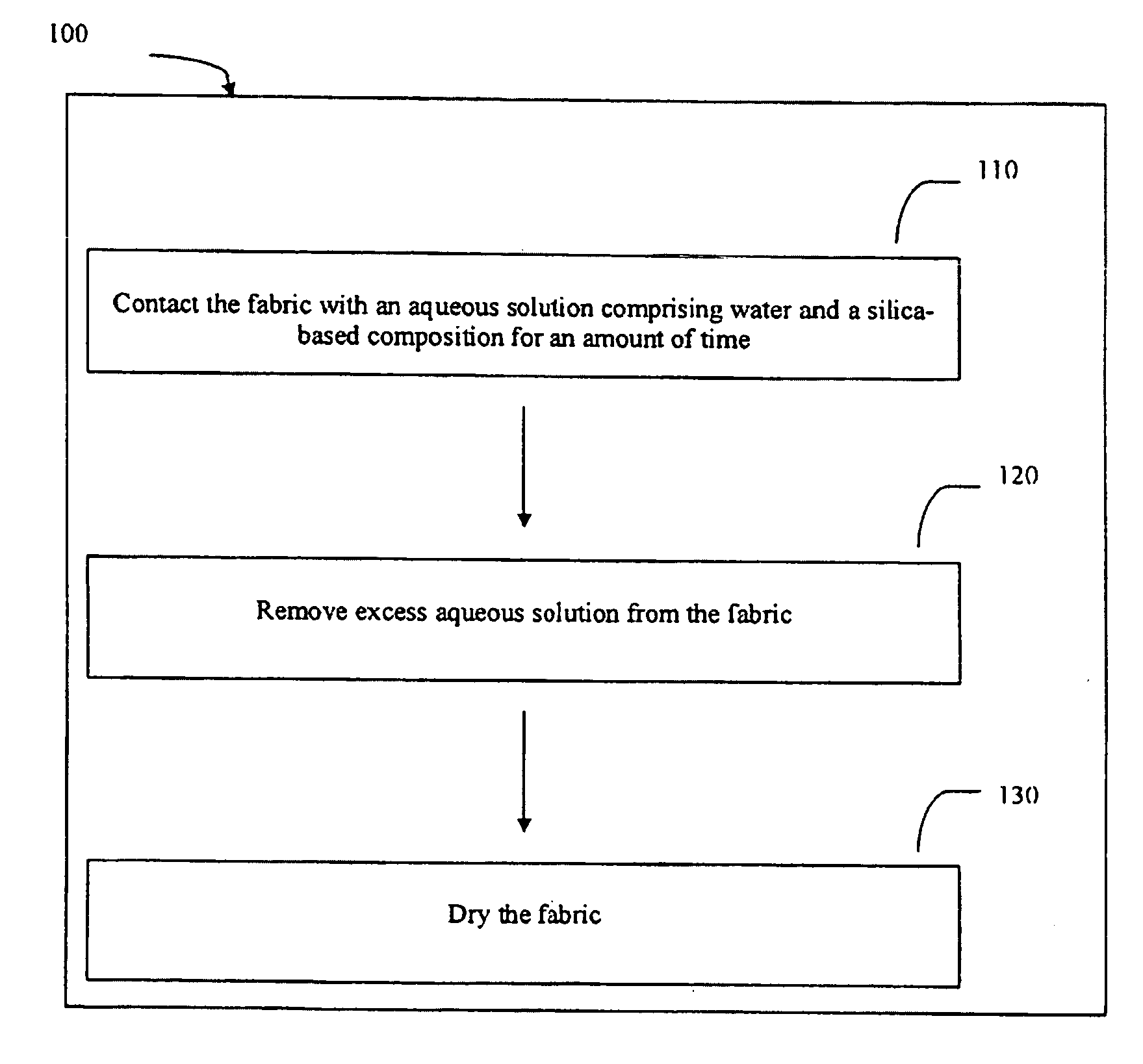

Method used

Image

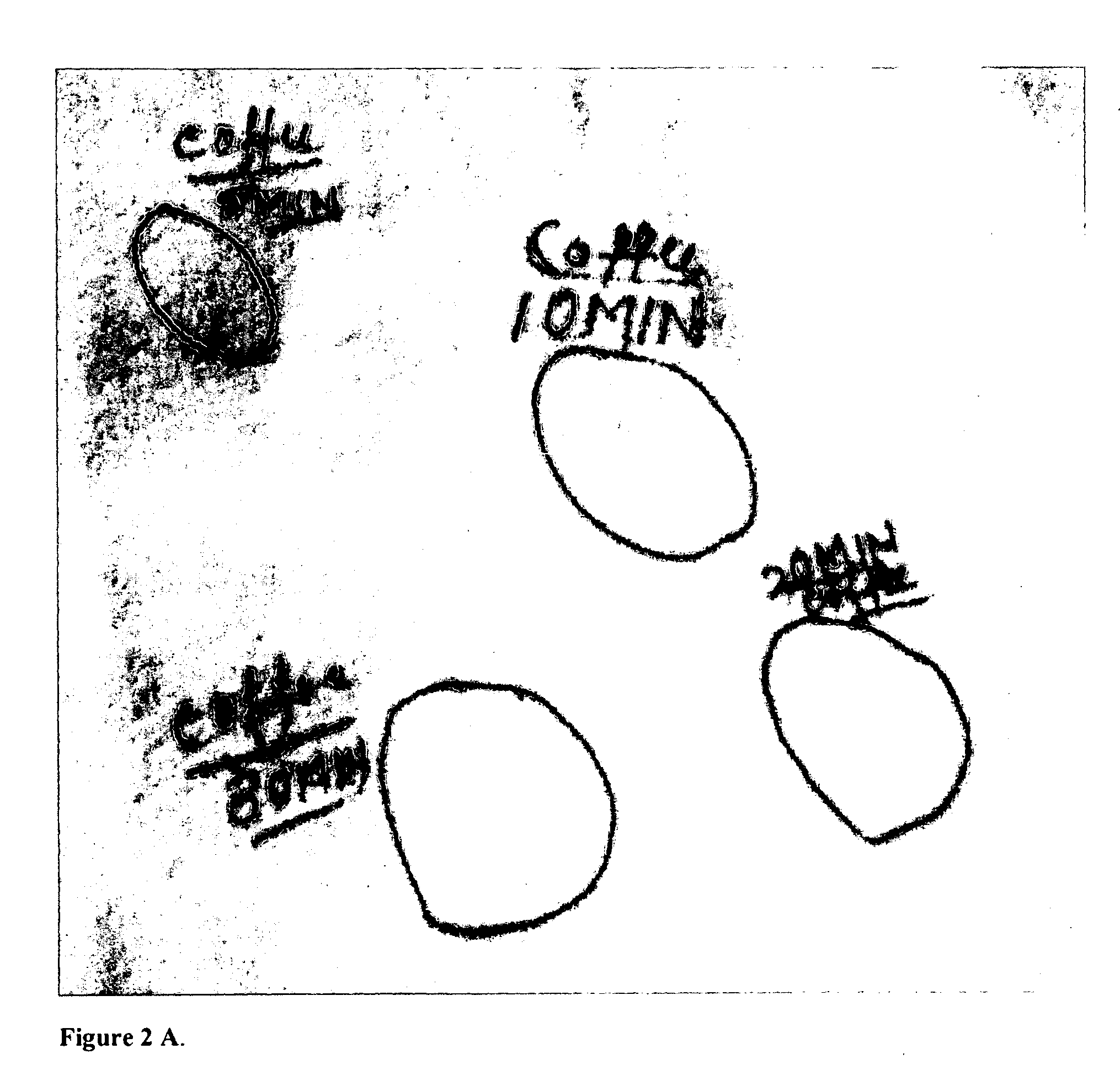

Examples

Embodiment Construction

[0023]The invention is directed to methods and compositions for improving the surface properties of fabric and other materials and substrates. In some embodiments, the methods and compositions may improve stain resistance and other properties of fabric or other materials. In the examples which follow, the beneficial properties achieved may be imparted to fabrics and other materials, such as glass, plastics, ceramics, composites, metal, paper, wood, and leather, as well as other substrates. The terms “halides,”“alkoxides,”“carboxylates,”“phosphates,”“sulfates”“hydroxides,”“hydrides” and “oxides” are intended to have their art-recognized meanings. The terms “alkyl,”“alkenyl,”“alkynyl,”“phenyl,”“benzenyl hydrocarbon,” and “fluorocarbon” are also intended to have their art-recognized meanings.

Silane-Based Compositions

[0024]The treatment composition of the present invention comprises organosilane monomers, oliogomers, particles, polymers and / or gels of organosilicate materials made from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com