Thermal production well filling vapor and nitrogen foam profile control technique

A technology of nitrogen foam and process method, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., which can solve the problems of reducing the efficiency and effect of heavy oil thermal recovery, reducing the effective steam sweep area, and decreasing the periodic oil-gas ratio. , to improve the effect of heat insulation, improve the effect of throughput and recovery, and reduce the effect of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] 1. Performance requirements of blowing agent

[0022] 2. Adapt to the conditions

[0023] (1) The heterogeneity of the oil reservoir is strong, because the foam is mainly produced in the large pores of the sand layer, so the oil layer with higher permeability is selected;

[0024] (2) Blocks with active edge and bottom water, heavy oil wells with comprehensive water cut>90%.

[0025] (3) After multiple huffs and puffs, the steam enters the channel, and the remaining oil is abundant within the steam heating radius;

[0026] (4) According to the test, when the residual oil saturation of steam flooding is below (18.2%), it starts to have a higher plugging ability, so choose the oil well with the high permeability strip with lower oil saturation;

[0027] (5) Oil layer thickness ≥ 5 meters;

[0028] (6) The downhole casing is intact.

[0029] 3. Nitrogen source and injection method

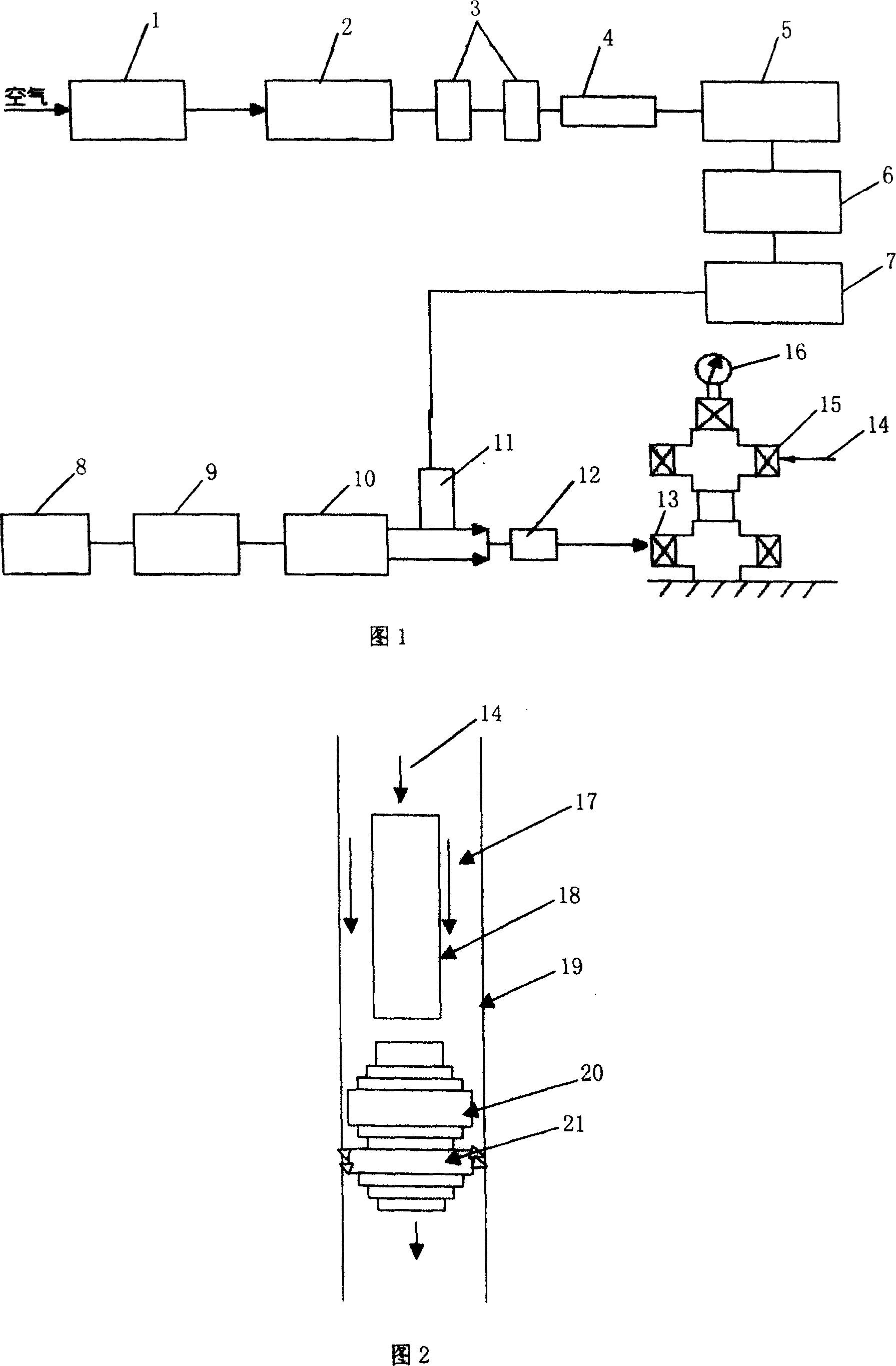

[0030] The process of nitrogen production using membrane air separation method nitroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com