Grade A fireproof light thermal insulating decorative integrated plate and production process thereof

A production process and one-piece board technology, applied in covering/lining, construction, building construction, etc., can solve problems such as high cost, white pollution, hollowing, etc., and achieve low thermal conductivity, long service life, and high economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

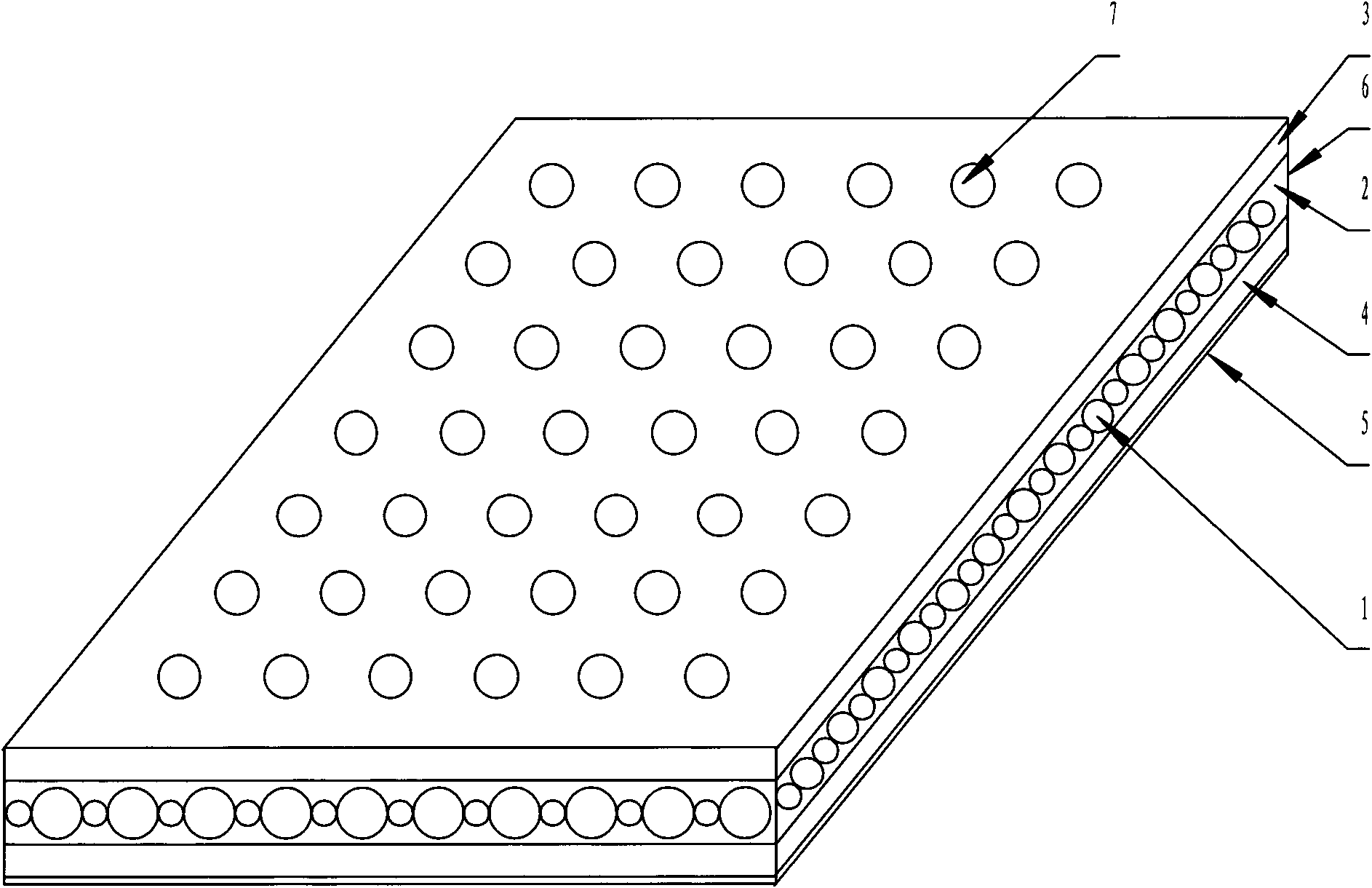

[0024] Such as figure 1 As shown in the present invention, the A-level fireproof light-weight thermal insulation and decorative integrated board of the present invention is composed of a middle splint 6, a bottom plate 3 and a panel 4. The closed-cell vitrified microbeads 1 have a particle size range of 0.5-1.5mm, 720-100 cement nails are distributed on each square meter of the bottom plate 3, and the diameter is 10-20mm, and the above-mentioned panel 4 is covered with protective film5.

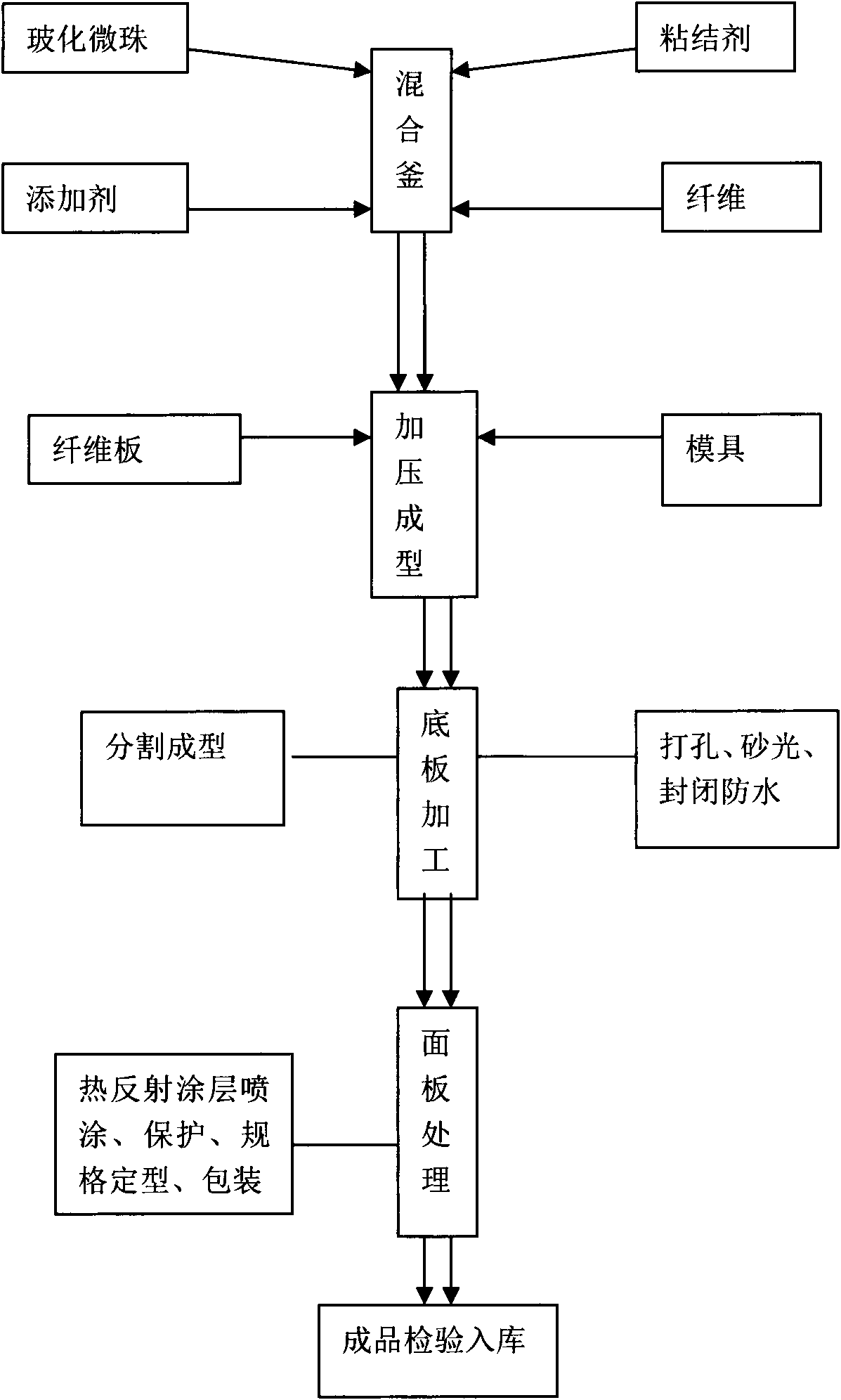

[0025] Such as figure 2 As shown, the production process of the above-mentioned A-level fireproof lightweight thermal insulation and decorative integrated board, the production process steps are as follows:

[0026] A. Production of integrated board and substrate: first mix vitrified microbeads 1 of different particle sizes evenly and then arrange them tightly. Under stirring, spray thermosetting adhesive 2 and make it fully mixed to allow thermosetting adhesive 2 to adhere evenly On the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com