High-efficiency paper base sound-absorbing material and preparation thereof

A sound-absorbing material and paper-based technology, which is applied in the direction of sound-emitting devices, instruments, and hydraulic-setting material layered products, can solve problems such as low strength, high brittleness, and fire hazards, and achieve simplified preparation processes and obvious sound-absorbing effects , Improve the absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

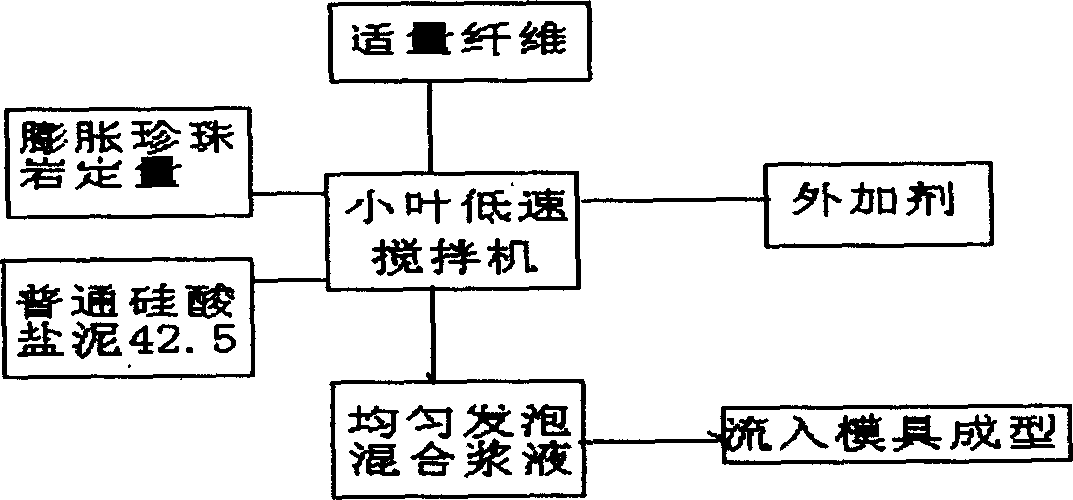

Method used

Image

Examples

Embodiment 1

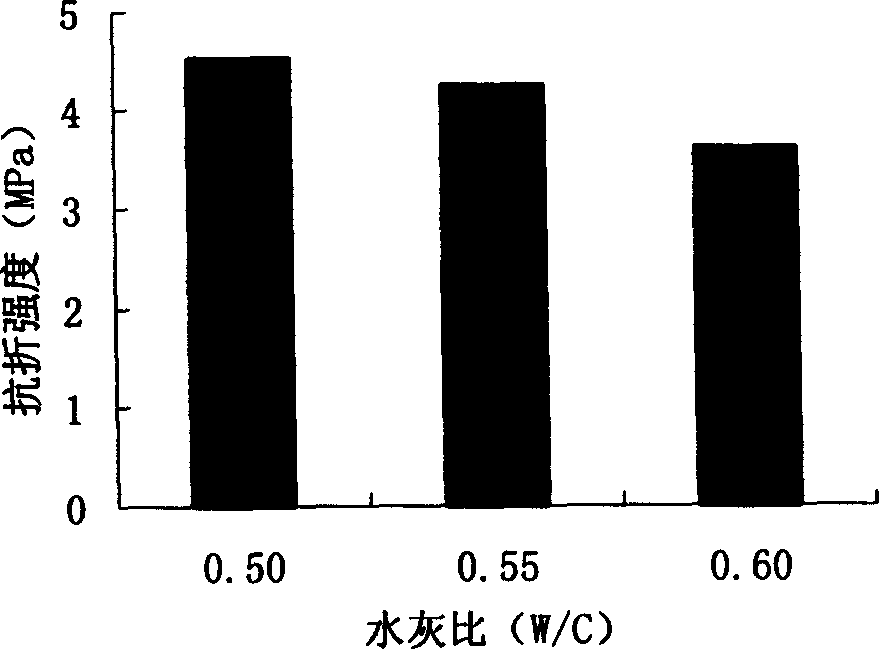

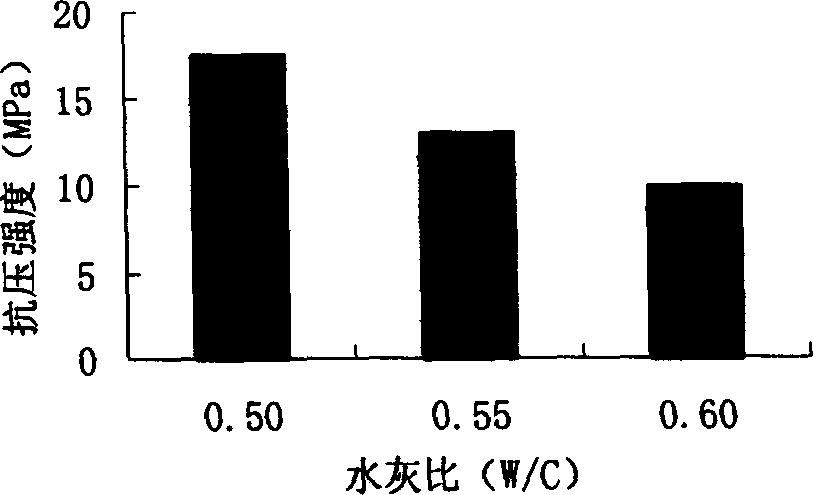

[0036] Example 1 The above-mentioned raw materials were used to prepare a paper-based sound-absorbing material with a water-cement ratio of 0.50. The composition and performance test results are listed in Table 2

Embodiment 2

[0037] Example 2 The above-mentioned raw materials were used to prepare a paper-based sound-absorbing material with a water-cement ratio of 0.55. The composition and performance test results are listed in Table 3

[0038] name

[0039] Composition of foam mortar

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com