High-performance pervious concrete system prepared from construction waste and preparing method thereof

A technology of permeable concrete and construction waste, which is applied to cohesive pavement, buildings, pavement details and other directions paved on site, which can solve the problems of incomplete utilization, inaccessibility, and large limitations in the actual use range, and reduce manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

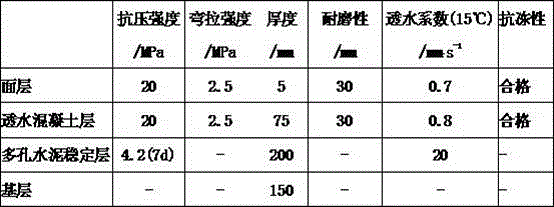

Embodiment 1

[0027] (1) Crush, reshape and sieve construction waste, and classify according to particle size < 4.75 mm, 4.75 mm-9.5 mm, 9.5 mm-16 mm, and 16 mm-26.5 mm.

[0028] Then match as follows,

[0029] Base: 100 parts of construction waste (of which < 4.75 mm, 80%, 4.75 mm-9.5 mm, 20%), 15 parts of water;

[0030] Porous cement stabilization layer: 100 parts of construction waste (of which < 4.75 mm, 10%, 4.75 mm-9.5 mm, 30%; 9.5mm-26.5 mm, 60%), 15 parts of cement, 6 parts of water;

[0031] Permeable concrete layer: 100 parts of construction waste (of which 4.75 mm-9.5 mm, 10%, 9.5 mm-16 mm, 90%), 20 parts of cement, 0.2 parts of water reducing agent (solid content 25%), 4 parts of water;

[0032] Surface layer: 100 parts of construction waste (4.75 mm-9.5 mm), 25 parts of cement, 0.5 parts of reinforcing agent, 0.25 parts of water reducing agent, and 5 parts of water;

[0033] The reinforcing agent is an acrylate emulsion with a solid content of 45-55%.

[0034] The materials...

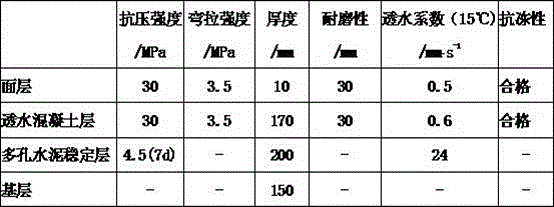

Embodiment 2

[0038] The construction waste is crushed, shaped and sieved, and classified according to particle size < 4.75 mm, 4.75 mm-9.5 mm, 9.5 mm-16 mm, and 16 mm-26.5 mm.

[0039] Then match as follows,

[0040] Base: 100 parts of construction waste (of which < 4.75 mm, 90%, 4.75 mm-9.5 mm, 10%), 20 parts of water;

[0041] Porous cement stabilization layer: 100 parts of construction waste (of which < 4.75 mm, 10%, 4.75 mm-9.5 mm, 25%; 9.5mm-26.5 mm, 65%), 15 parts of cement, 5 parts of water;

[0042] Permeable concrete layer: 100 parts of construction waste (of which 4.75 mm-9.5 mm, 30%, 9.5 mm-16 mm, 70%), 25 parts of cement, 0.25 parts of water reducing agent (solid content 25%), 6 parts of water;

[0043] Surface layer: 100 parts of construction waste (4.75 mm-9.5 mm), 25 parts of cement, 0.5 parts of reinforcing agent, 0.25 parts of water reducing agent, and 5 parts of water;

[0044] The reinforcing agent is styrene-butadiene emulsion with a solid content of 45-55%.

[0045]...

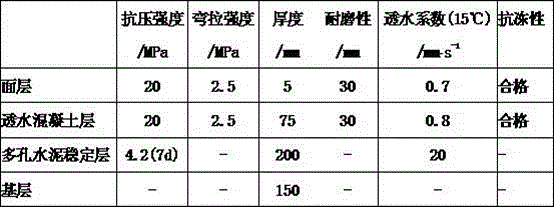

Embodiment 3

[0049] The construction waste is crushed, shaped and sieved, and the particle size is classified according to < 4.75 mm, 4.75 mm-9.5 mm, 9.5 mm-16 mm, and 16 mm-26.5 mm.

[0050] Then match as follows,

[0051] Base: 100 parts of construction waste (of which, < 4.75 mm, 90%, 4.75 mm-9.5 mm, 10%), 20 parts of water;

[0052] Porous cement stabilization layer: 100 parts of construction waste (of which < 4.75 mm, 8%, 4.75 mm-9.5 mm, 20%; 9.5 mm-26.5 mm, 72%), 10 parts of cement, 4 parts of water;

[0053] Permeable concrete layer: 100 parts of construction waste (4.75 mm-9.5 mm, 30%, 9.5 mm-16 mm, 70%), 25 parts of cement, 0.25 parts of water reducing agent (solid content 25%), 6 parts of water;

[0054] Surface layer: 100 parts of construction waste (4.75 mm-9.5 mm), 30 parts of cement, 1.0 parts of reinforcing agent, 0.3 parts of water reducing agent, and 7.5 parts of water;

[0055] The reinforcing agent is styrene-acrylic emulsion with a solid content of 45-55%.

[0056]Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com