A kind of paving brick prepared by using waste clay brick and its preparation method

A technology for discarding clay bricks and paving bricks is applied in the field of building materials to achieve the effect of improving performance and inhibiting accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] For paving bricks prepared from waste clay bricks, the raw materials used in parts by weight are: 100 parts of waste clay bricks, 10 parts of cement, 15 parts of water, 0.3 parts of reinforcing agent, and 0.5 parts of surface modifier.

[0020] The reinforcing agent is acrylate emulsion with a solid content of 45-55%.

[0021] The surface modifier is diethanolamine.

[0022] The preparation method is as follows: crushing, reshaping and sieving waste clay bricks. The particle size distribution of waste clay brick powder is: < 0.15mm, 20%; 0.15mm-1.5mm, 50%; 4.75mm-9.5mm, 30%. Mix waste clay brick powder with particle size < 0.15mm and surface modifier evenly. Then waste clay bricks, cement, water, reinforcing agent and other materials were mixed in proportion, stirred evenly, molded under a pressure of 50 MPa, demoulded, and maintained for 28 days to obtain paving brick products. The performance indicators are shown in Table 1.

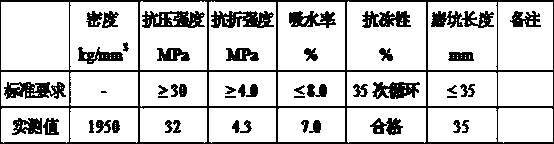

[0023] Table 1. Performance parameters ...

Embodiment 2

[0026] The paving bricks prepared by using waste clay bricks, the raw materials used are 100 parts by weight of waste clay bricks, 15 parts of cement, 0.3 parts of reinforcing agent, 0.75 parts of surface modifier and 12 parts of water.

[0027] The reinforcing agent is styrene-butadiene emulsion with a solid content of 45-55%.

[0028] Surface modifier triethanolamine.

[0029] The waste clay bricks are crushed, shaped and sieved. The particle size distribution of waste clay bricks is: < 0.15 mm, 20%; 0.15mm-1.5mm, 60%; 4.75 mm-9.5 mm, 20%. Mix waste clay brick powder with particle size < 0.15mm and surface modifier evenly. Then waste clay bricks, cement, water, reinforcing agent and other materials were mixed, stirred evenly, and then formed under a pressure of 55 MPa, demoulded, and standard curing for 28 days to obtain paving brick products. The performance indicators are shown in Table 2.

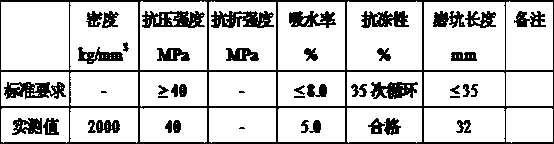

[0030] Table 2. Performance parameters of paving brick products prepared from wa...

Embodiment 3

[0033] The paving bricks prepared by using waste clay bricks, the raw materials used are 100 parts by weight of waste clay bricks, 18 parts of cement, 0.4 parts of reinforcing agent, 1 part of surface modifier and 12 parts of water.

[0034] The reinforcing agent is styrene-acrylic emulsion with a solid content of 45-55%.

[0035] The surface modifier is coconut acid diethanolamide.

[0036] The waste clay bricks are crushed, shaped and sieved, and the particle size distribution of waste clay brick powder is: < 0.15 mm, 15%; 0.15mm-1.5mm, 55%; 4.75 mm-9.5 mm, 30%. Mix waste clay brick powder with particle size < 0.15 mm and surface modifier evenly. Then mix waste clay bricks, cement, water, reinforcing agent and other materials, stir evenly, and then mold them under a pressure of 60MPa, demould, and standard curing for 28 days. The performance indicators of paving brick products are shown in Table 3.

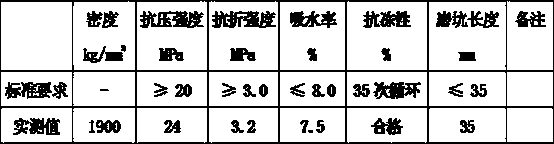

[0037] Table 3. Performance parameters of paving brick products prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com