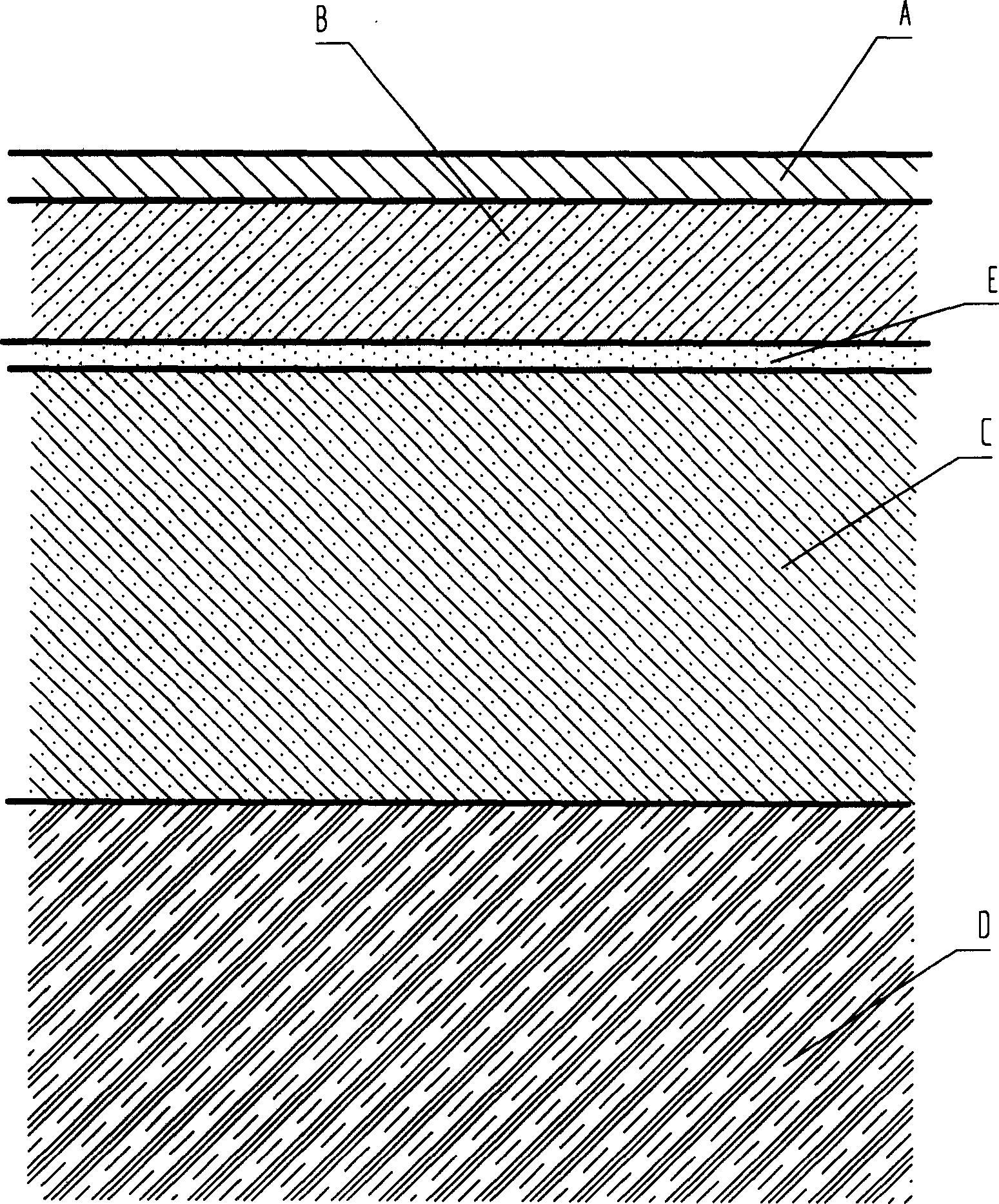

New road surface structure layer

A kind of pavement structure and new technology, applied in the direction of roads, roads, condensed pavement paved on site, etc., can solve the problems of reducing waterproof performance, road water damage, pavement pulling, etc., to improve the ability to resist rutting, extend the road Longevity, effect of preventing lateral displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The material components of porous modified cement concrete are calculated by weight: 500 kilograms of cement; 1800 kilograms of crushed stones with a particle size of 20 mm; 160 kilograms of water; 24 kilograms of cement modifier; the prepared porous modified cement concrete test block , its compressive strength is: 30.3Mpa, flexural strength 5.0Mpa, porosity 6.8%.

Embodiment 2

[0024] The material components of porous modified cement concrete are calculated by weight: 200 kilograms of cement; 1400 kilograms of crushed stones with a particle size of 5 mm; 100 kilograms of water; 5 kilograms of cement modifier; the prepared porous modified cement concrete test block , the compressive strength is: 3.5Mpa, the flexural strength is 1.3Mpa, and the porosity is 25%.

Embodiment 3

[0026] The material components of the porous modified cement concrete are by weight: 300 kilograms of cement; 1500 kilograms of crushed stones with a particle size of 10 mm; 115 kilograms of water; 17.25 kilograms of cement modifier; the prepared porous modified cement concrete test block , its compressive strength is: 15Mpa, flexural strength 2.5Mpa, porosity 22%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com