Environment-friendly all-permeable water-permeable concrete based on waste concrete and preparation method thereof

A technology for waste concrete and permeable concrete, applied in the field of building materials, can solve the problems of a single permeable layer, restrict the popularization and application of permeable concrete, and easily block permeable pores, and achieve the effects of improving aesthetics, preventing system blockage, and good permeation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The environmental protection fully permeable color permeable concrete based on waste concrete and the preparation method thereof provided by the present invention comprise the following steps:

[0035] (1) After the waste concrete is broken and screened, four kinds of regenerated aggregates of 2.36mm~4.75mm, 4.75mm~9.5mm, 9.5mm~16.5mm and 4.75mm~26.5mm are obtained; the waste concrete Regenerated aggregate, wherein 4.75mm-9.5mm and 9.5mm-16.5mm need to be strengthened by a strengthening agent; preferably, the strengthening agent is one of potassium methyl silicate or water glass, and the mass concentration is 3% to 45%. The strengthening time is 3 to 8 minutes; after strengthening, the water absorption rate of the recycled aggregate is reduced by 2% to 4%.

[0036] (2) Add waste concrete recycled aggregates of the same particle size, degradable waste plastic particles and water plant silt dry pellets into the mixer at a certain ratio, mix and stir, and add part of the m...

Embodiment 1

[0044] The permeable concrete is divided into three layers: a permeable upper layer, a permeable lower layer, and a porous cement stabilization layer.

[0045]The specific blending ratio is: ① waste concrete recycled aggregate in the permeable upper layer: degradable waste plastic particles: water plant silt dry pellet mass ratio is 90:7:3, and 3‰ of red iron oxide pigment is added; ② The mass ratio of waste concrete recycled aggregate in the permeable lower layer: degradable waste plastic particles: water plant sludge dry pellets is 93:5:2;

[0046] ③ The mass ratio of waste concrete recycled aggregate in the porous cement stabilization layer: degradable waste plastic particles: water plant sludge dry pellets is 83:12:5.

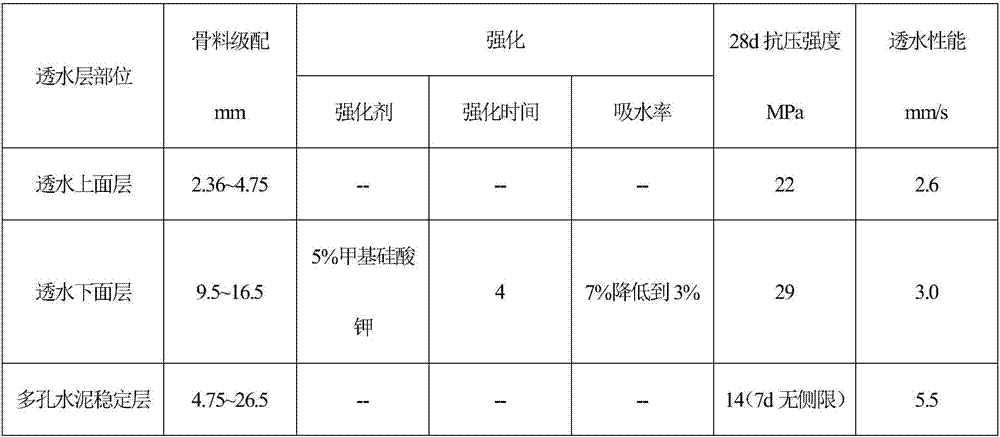

[0047] Please refer to Table 1 below for specific performance information.

[0048] Table 1 Performance of permeable concrete system

[0049]

Embodiment 2

[0051] The permeable concrete is divided into a permeable upper layer, a permeable lower layer, and a porous cement stabilization layer. The specific mixing ratio is as follows: ① waste concrete recycled aggregate in the permeable upper layer: degradable waste plastic particles: water plant sludge drying ball The particle mass ratio is 91:6:3; ②The waste concrete recycled aggregate in the permeable lower layer: the degradable waste plastic particles: the water plant sludge dry pellet mass ratio is 95:3:2; ③The waste concrete in the porous cement stabilization layer The mass ratio of recycled aggregate: degradable waste plastic particles: dry pellets of water plant sludge is 80:15:5.

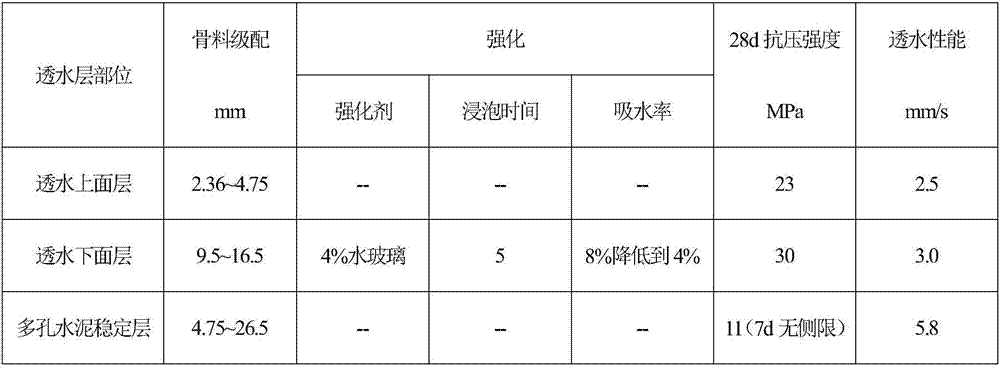

[0052] Please refer to Table 2 below for specific performance information.

[0053] Table 2 Performance of pervious concrete system

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com