Porous cement concrete cement overlay having bond coat laying on bituminous surface and construction method therefor

A technology of cement concrete and asphalt pavement, which is applied to cohesive pavement paved on site, roads, roads, etc., can solve the problems of poor durability, small deformation capacity, and sensitive support conditions of asphalt materials, so as to improve service performance, Enhanced deformation ability, increased adaptability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] An example below:

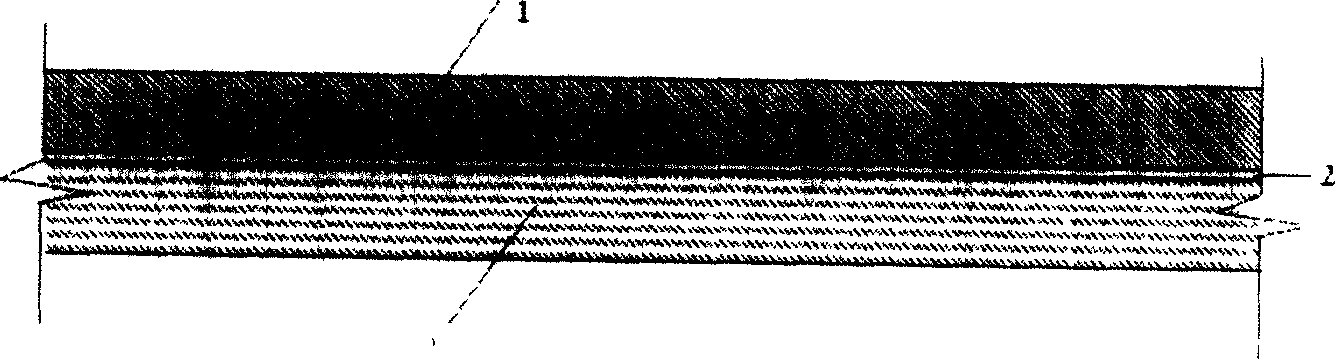

[0029] Its structure is asphalt surface layer 3, adhesive layer 2, porous cement concrete overlay layer 1, adhesive layer 2 is laid on the asphalt surface layer 3, and porous cement concrete overlay layer 1 is paved on the upper surface of the adhesive layer 2.

[0030] The specific embodiment of the present invention is: at first cleaning the bituminous concrete pavement 3 that formed earlier, then polymer material elastic acrylic emulsion, cement, water, according to the weight mixing ratio—polymer: cement: water:=1:6:1 , using artificial mixing, and then artificially brush the formed polymer cement slurry on the asphalt concrete road surface, the polymer cement slurry will form a bonding layer 2 after solidification, when the acrylic cement slurry is not completely solidified, use a cement concrete mixer to prepare Porous cement concrete with a certain dry consistency, suitable for asphalt paver self-leveling and self-vibration process, its weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com