Color pavement formed by spraying on honey-combed cement concrete facing and construction method therefor

A cement concrete and surface layer technology, which is applied to cohesive pavement paved on site, roads, roads, etc., can solve the problems of surface material durability that cannot meet the requirements, no obvious improvement in noise pollution, and no water permeability, etc., to achieve It is convenient for large-scale construction, remarkable economy, and the effect of three-dimensional color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following example

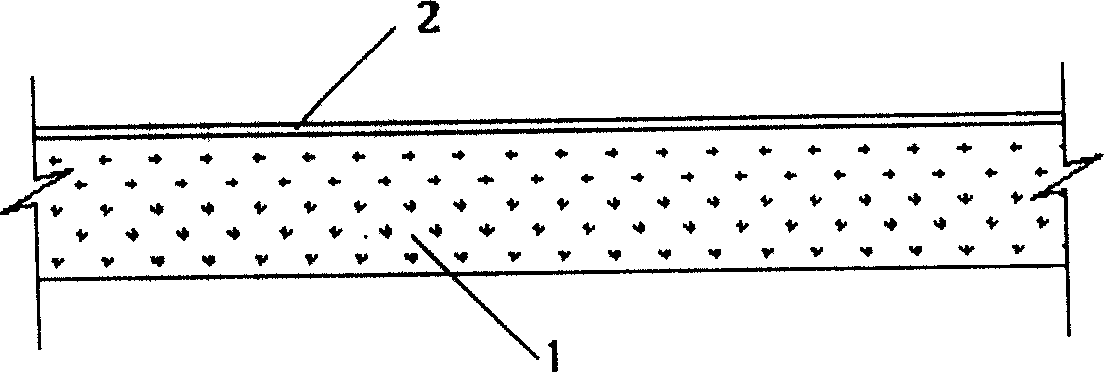

[0046] Its structure is a porous cement concrete surface layer 1 and a colored surface layer 2, and the porous cement concrete surface layer 1 has a colored surface layer 2 on it.

[0047] First, the weight ratio is - cement: crushed stone: sand: water = 350kg: 1700kg: 0kg: 110kg, using a concrete mixer to mix evenly to form cement concrete rich in pores, wherein the cement is P.O42.5 ordinary silicon Salt cement, the crushed stone is granite, a single grade with a particle size range of 5-10mm. Use asphalt paver with vibration function to pave the porous cement concrete surface layer 1, use the self-vibration function of the paver to ensure that the compaction degree of the porous cement concrete surface layer 1 is not less than the design value, and clean the porous cement concrete surface layer 1 after 3 days of curing Impurities and floating ash on the surface of the cement concrete surface layer, when the porous cement concrete surface laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com