Preparation method of directional porous special cement

A cement and cement-based technology, which is applied in the production of porous materials and the preparation of directional porous cement, can solve the problems of few reports and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

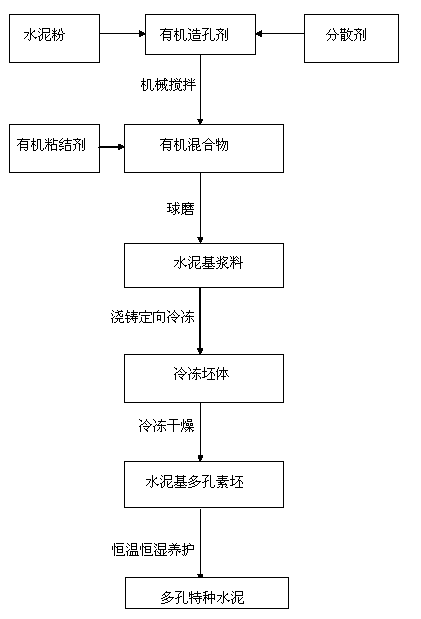

Method used

Image

Examples

Embodiment 1

[0044] A preparation method of directional porous cement, comprising the following steps:

[0045] The first is the preparation of cement-based slurry: take Portland cement powder 100g, tert-butanol 100g, ammonium polyacrylate 0.5g, ethyl cellulose 1g according to the ratio of parts by mass, put Portland cement powder into tert-butanol , add ammonium polyacrylate and perform mechanical stirring for 1 hour to obtain a fully mixed mixture. Using zirconia as the ball milling medium, put the organic mixture and ethyl cellulose into a stainless steel ball mill tank for 24 hours to make the cement-based mixture The material is uniformly dispersed, thereby obtaining a cement-based slurry with a solid content of 50wt%;

[0046] said

[0047]

[0048] The second is the production of the frozen body: put the fully mixed cement-based slurry into a vacuum drying box for vacuum degassing, and then cast the cement-based slurry after removing air bubbles into a self-made freezing mold fo...

Embodiment 2

[0054] A preparation method of directional porous cement, comprising the following steps:

[0055] The first is the preparation of cement-based slurry: Take 80g of composite Portland cement powder, 120g of alkene, 0.4g of citric acid, and 1.5g of polyvinyl butyral according to the ratio of parts by mass, and put the composite Portland cement powder into Add citric acid to olefin, and carry out mechanical stirring for 5 hours to obtain a fully mixed mixture. Using zirconia as the ball milling medium, put the mixture and polyvinyl butyral in a stainless steel ball mill tank for 12 hours to make the cement The base mixed material is uniformly dispersed to obtain a cement-based slurry with a solid content of 40wt%;

[0056] said

[0057]

[0058] The second is the production of the frozen body: put the fully mixed cement-based slurry into a vacuum drying box for vacuum degassing, and then cast the cement-based slurry after removing air bubbles into a self-made freezing mold fo...

Embodiment 3

[0064] A preparation method of directional porous cement, which is special in that it comprises the following steps:

[0065] The first is the preparation of cement-based slurry: Take 60g of ordinary Portland cement powder, 140g of ketone, 0.3g of methacrylic acid, and 2g of polyethylene according to the ratio of parts by mass, put the ordinary Portland cement powder into the ketone, Add methacrylic acid and carry out mechanical stirring for 1.5 hours to obtain a fully mixed mixture. Use alumina balls as the ball milling medium, put the mixture and polyethylene into a stainless steel ball mill tank for 36 hours to make the cement-based mixed material evenly dispersed , so as to obtain a cement-based slurry with a solid content of 30wt%;

[0066] said

[0067]

[0068] The second is the production of the frozen body: put the fully mixed cement-based slurry into a vacuum drying box for vacuum degassing, and then cast the cement-based slurry after removing air bubbles into a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com